Cutter surface plasma vacuum coating pretreatment process

A surface plasma and vacuum coating technology, used in ion implantation coating, vacuum evaporation coating, metal material coating process, etc., can solve the problems of poor coating adhesion, incomplete cutting edge, failure, etc. strength, preventing film cracking, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

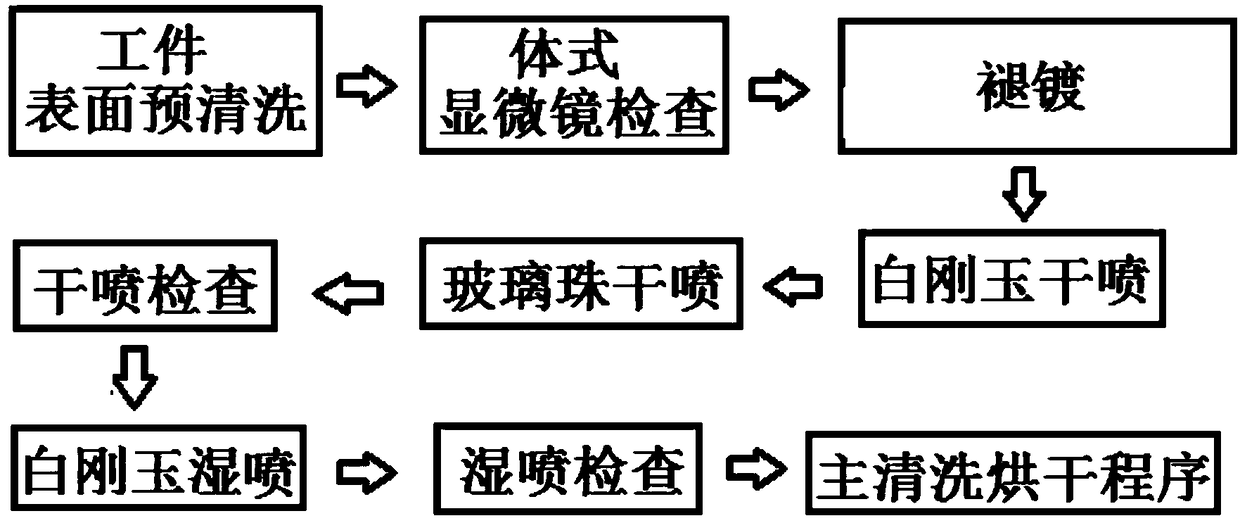

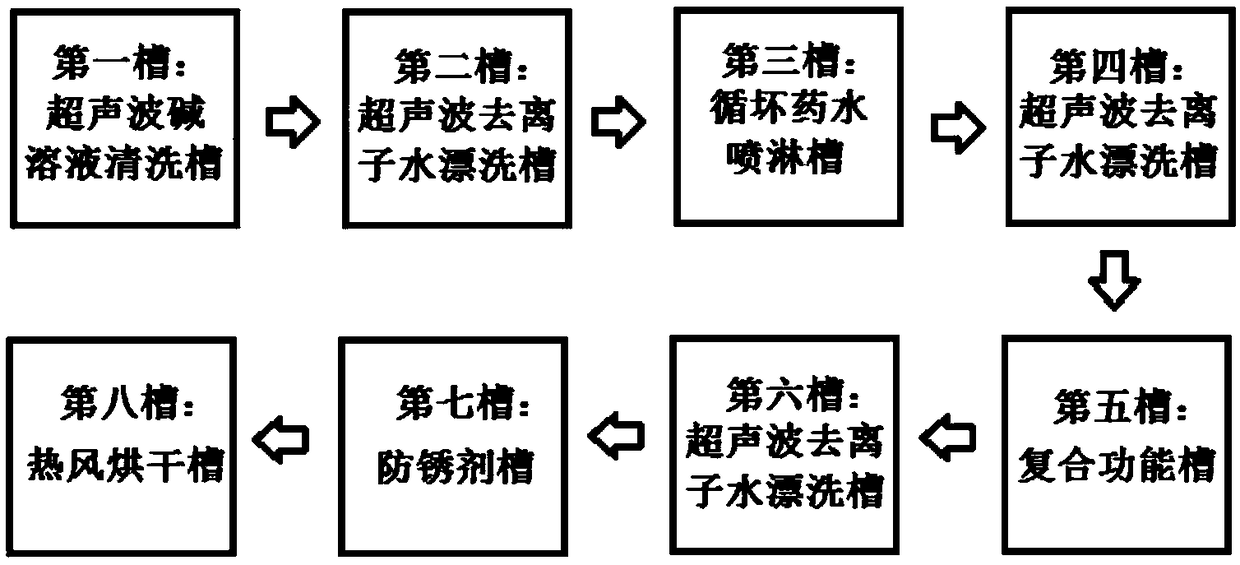

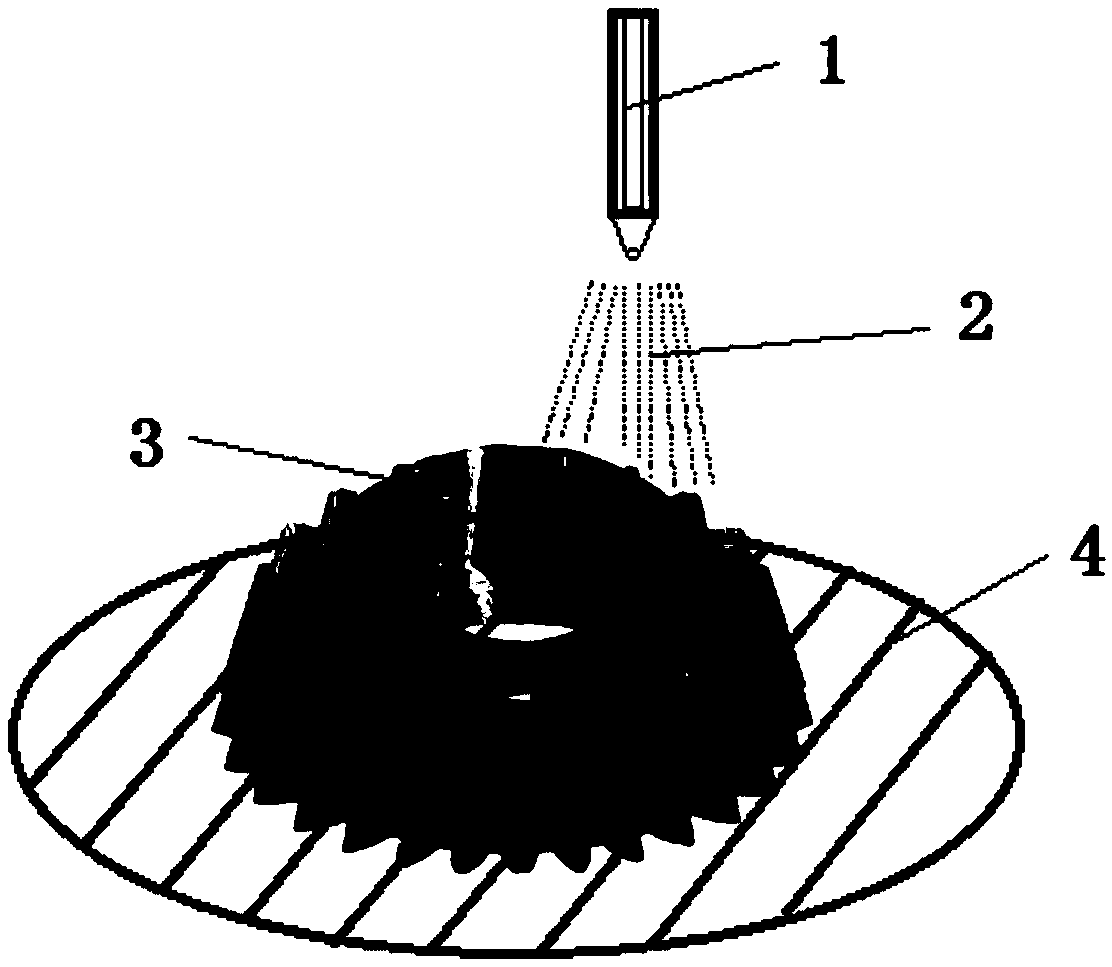

[0029] see figure 1 and figure 2 .

[0030] The pre-treatment process of plasma vacuum coating on the tool surface includes the following steps:

[0031] (1) Pre-cleaning of tool surface

[0032] There are usually a lot of oil stains, waxes and other pollutants on the surface of the cutting tool when the material comes in. Only after pre-cleaning to remove large macroscopic pollutants can it be convenient to observe the defects under the microscope. The surface pre-cleaning solution is the solution used in the first tank of the following main cleaning, so as to make full use of it, and the used surface pre-cleaning solution is used as hazardous waste for recycling.

[0033] (2) Stereo microscope inspection

[0034] After pre-cleaning, the tool is rinsed with clear water, dried with a high-pressure air gun, and then inspected under a stereo microscope. The inspection items include whether there are defects such as chipping, cracks, burrs, and blunt cutting edges on the sur...

Embodiment 2

[0063] Comparative experiment of different pretreatment processes

[0064] Table 2 is a comparison of different pretreatment processes, where the four processes A, B, C, and D correspond as follows:

[0065] A: Step (1)+(2)+(3)+(4)+(5)+(6)+(7)+(8)+(9);

[0066] B: Step (1)+(2)+(4)+(5)+(6)+(7)+(8)+(9);

[0067] C: step (1)+(2)+(3)+(4)+(7)+(8)+(9);

[0068] D: Step (1)+(2)+(3)+(4)+(5)+(6)+(9).

[0069] Table 2 Comparison of different pretreatment processes

[0070]

[0071] The surface cleanliness is based on the American ASTM D 2200 standard, in which SSPC SP1~10, the larger the number, the worse the surface cleanliness. It can be seen from Table 1 that B, C, and D in the four pretreatment processes will all cause the decline of the tool surface cleanliness , which has a greater impact on the bonding force between the coating and the substrate and the service life of the tool. The bonding force test adopts the German VDI3198 standard (HF1~HF6), HF1 represents the best bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com