Catalyst for low-temperature catalytic combustion of volatile aromatic hydrocarbon organic matters and method for preparing catalyst

A low-temperature catalysis and catalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, combustion methods, etc., can solve the problems of unfavorable industrial production and high requirements for ultrasonic pretreatment, and achieves low cost, low cost, and high requirements for ultrasonic pretreatment. The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

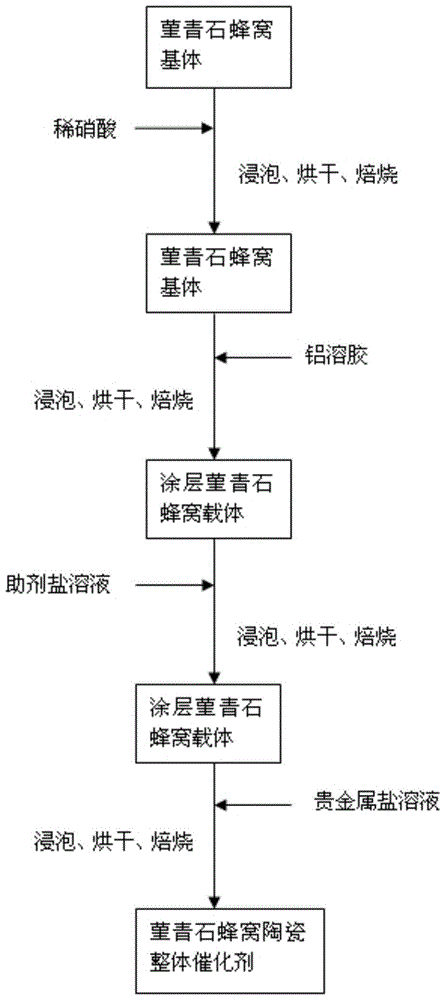

Method used

Image

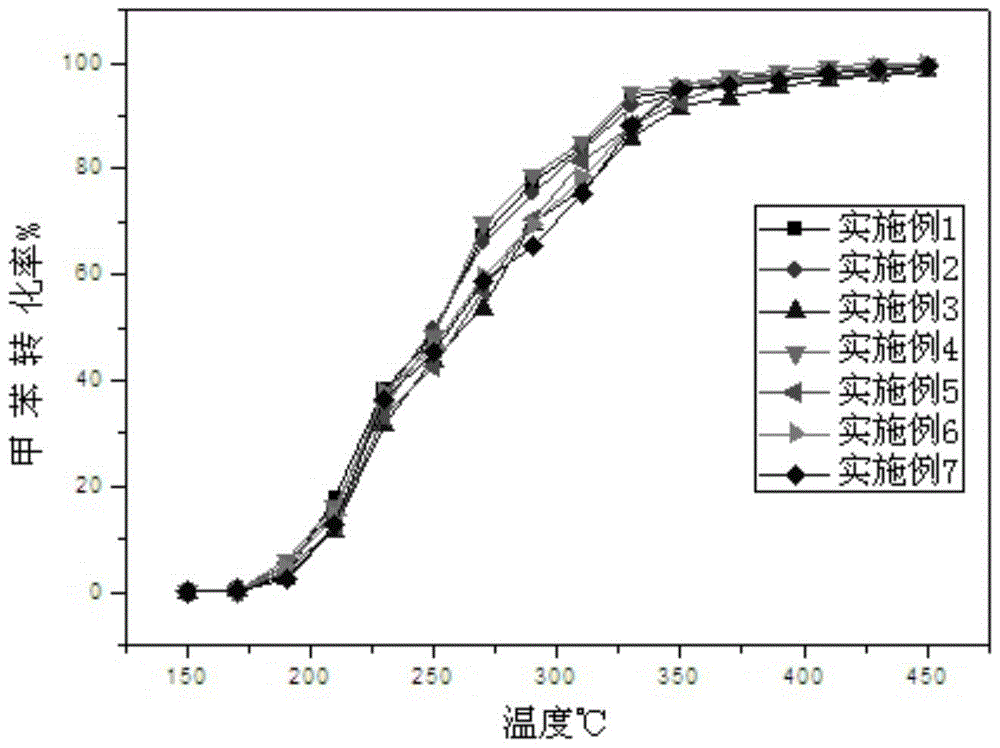

Examples

Embodiment 1

[0033] Pretreatment of cordierite honeycomb ceramics: completely immerse cordierite honeycomb ceramics in 1wt% nitric acid solution for 1 hour, rinse with deionized water 3 times after taking out, blow off residual liquid, and dry at 90°C for 1 hour. Calcined at 400° C. for 2 hours to obtain a surface-activated cordierite honeycomb ceramic carrier.

[0034] Preparation of aluminum sol: Add 10 grams of aluminum isopropoxide into 90 ml of deionized water, heat to 85° C. for stirring and hydrolysis. After complete hydrolysis, it becomes turbid. Slowly add a certain amount of dilute nitric acid of about 4ml5mol / L to degumming. The calculated content is 10wt%.

[0035] Coating of aluminum coating: After immersing the treated cordierite honeycomb carrier in aluminum sol for 1 hour, filter out the solution in the pores, dry at 120°C for 1 hour, and bake at 700°C for 2 hours to obtain alumina-coated cordierite Cellular carrier. The alumina loading reached 8% after coating.

[0036...

Embodiment 2

[0040] Pretreatment of cordierite honeycomb ceramics: completely immerse cordierite honeycomb ceramics in 1wt% sulfuric acid solution for 1 hour, rinse with deionized water 3 times after taking out, blow off the residual liquid, and dry at 120°C for 5 hours. Calcined at 700° C. for 6 hours to obtain a surface-activated cordierite honeycomb ceramic carrier.

[0041]Preparation of aluminum sol: add 26 grams of pseudoboehmite powder into 120ml of deionized water, heat to 85°C under stirring, slowly add a certain amount of dilute nitric acid of about 6ml5mol / L dropwise, control the pH value of the solution at 2~4, after stirring Standing and aging for 24 hours, a transparent aluminum sol with certain fluidity was obtained, and the content was 10wt% based on alumina.

[0042] Coating of aluminum coating: After immersing the treated cordierite honeycomb carrier in aluminum sol for 3 hours, filter out the solution in the pores, dry at 90°C for 5 hours, and bake at 400°C for 6 hours t...

Embodiment 3

[0047] Pretreatment of cordierite honeycomb ceramics: completely immerse cordierite honeycomb ceramics in 1wt% hydrochloric acid solution for 1 hour, rinse with deionized water 3 times after taking out, blow off residual liquid, and dry at 110°C for 3 hours. Calcined at 550° C. for 3 hours to obtain a surface-activated cordierite honeycomb ceramic carrier.

[0048] Aluminum sol preparation: 40 grams of AlCl 3 ·6H 2 Dissolve in 100ml of deionized water with stirring, let it stand for 30 minutes after completely dissolving and cooling, then dissolve 10 grams of 200-mesh aluminum powder in AlCl with stirring 3 In the solution, heat to 80-90°C at the same time to completely dissolve the aluminum powder into a sol, control the pH value of the solution at 2-4, and stand and age for 24 hours to obtain an aluminum sol, the content of which is 10wt% based on alumina.

[0049] Coating of aluminum coating: After immersing the treated cordierite honeycomb carrier in aluminum sol for 1 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com