Polycrystalline diamond clad sheet and preparation method thereof

A polycrystalline diamond and composite sheet technology, applied in chemical instruments and methods, metal layered products, layered products, etc., can solve the problems of improving the thermal conductivity of polycrystalline diamond sheets and reducing the wear resistance of polycrystalline diamond sheets, etc. To achieve the effect of weakening graphitization, the preparation method is simple and easy to operate, and the impact resistance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

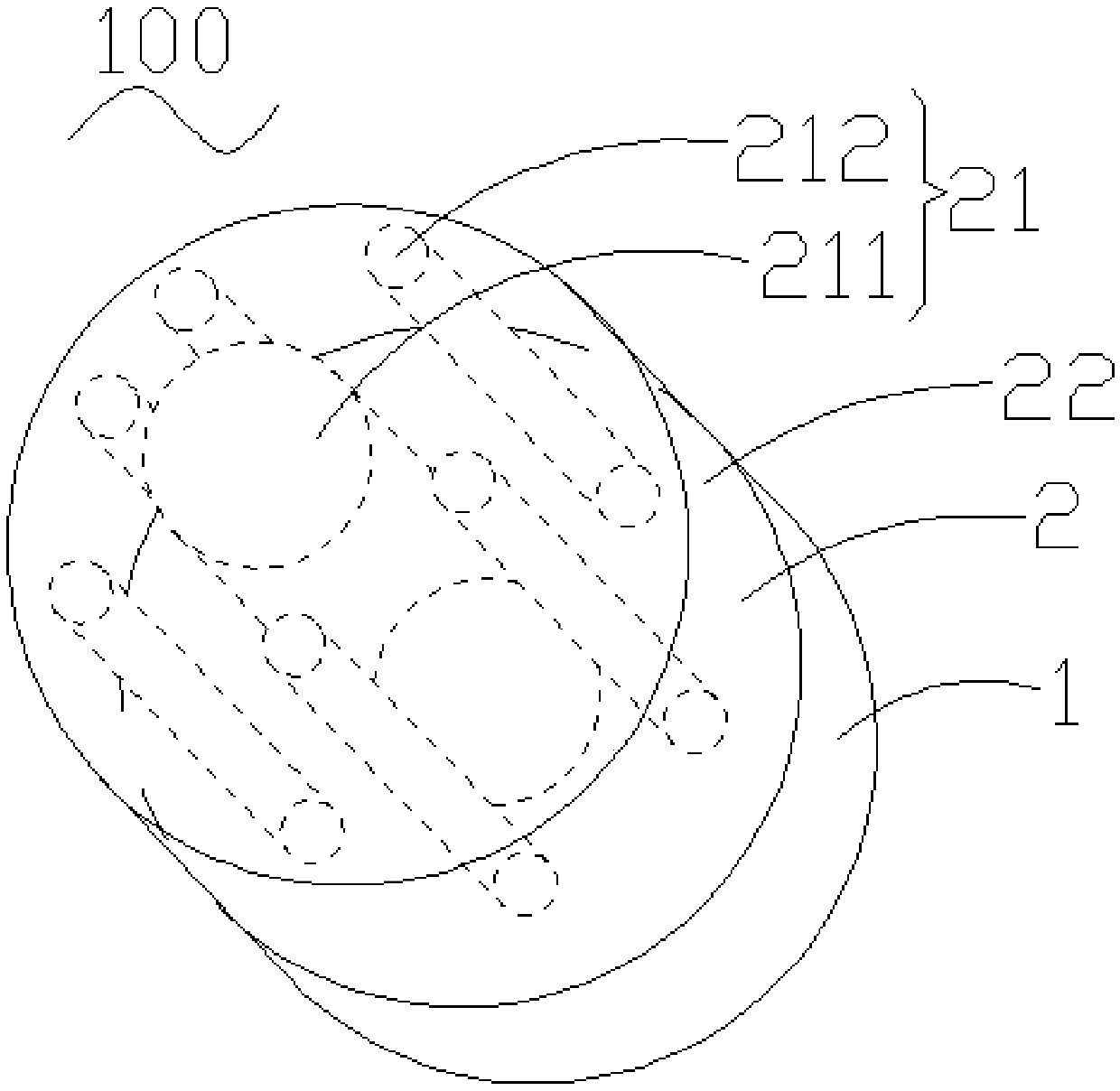

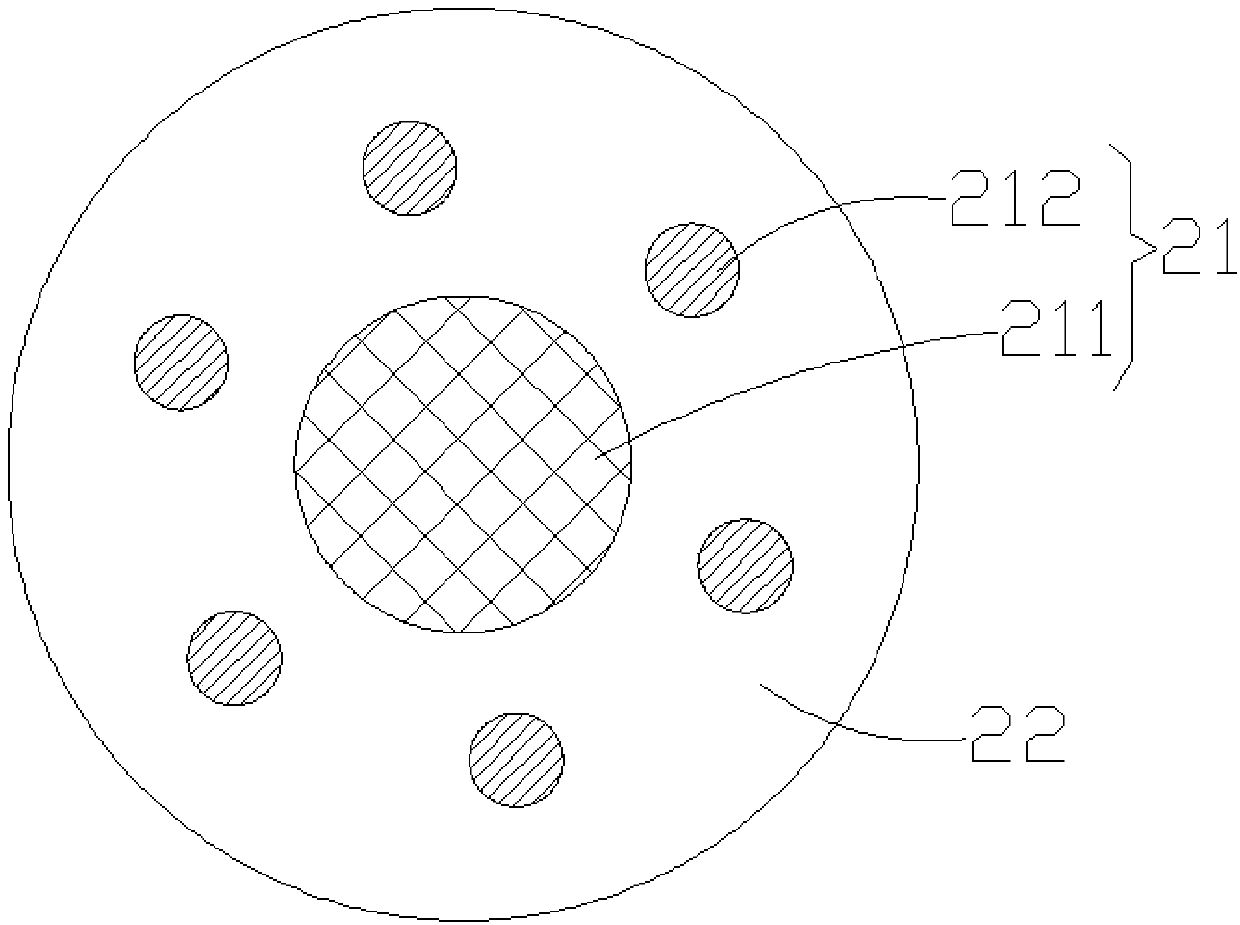

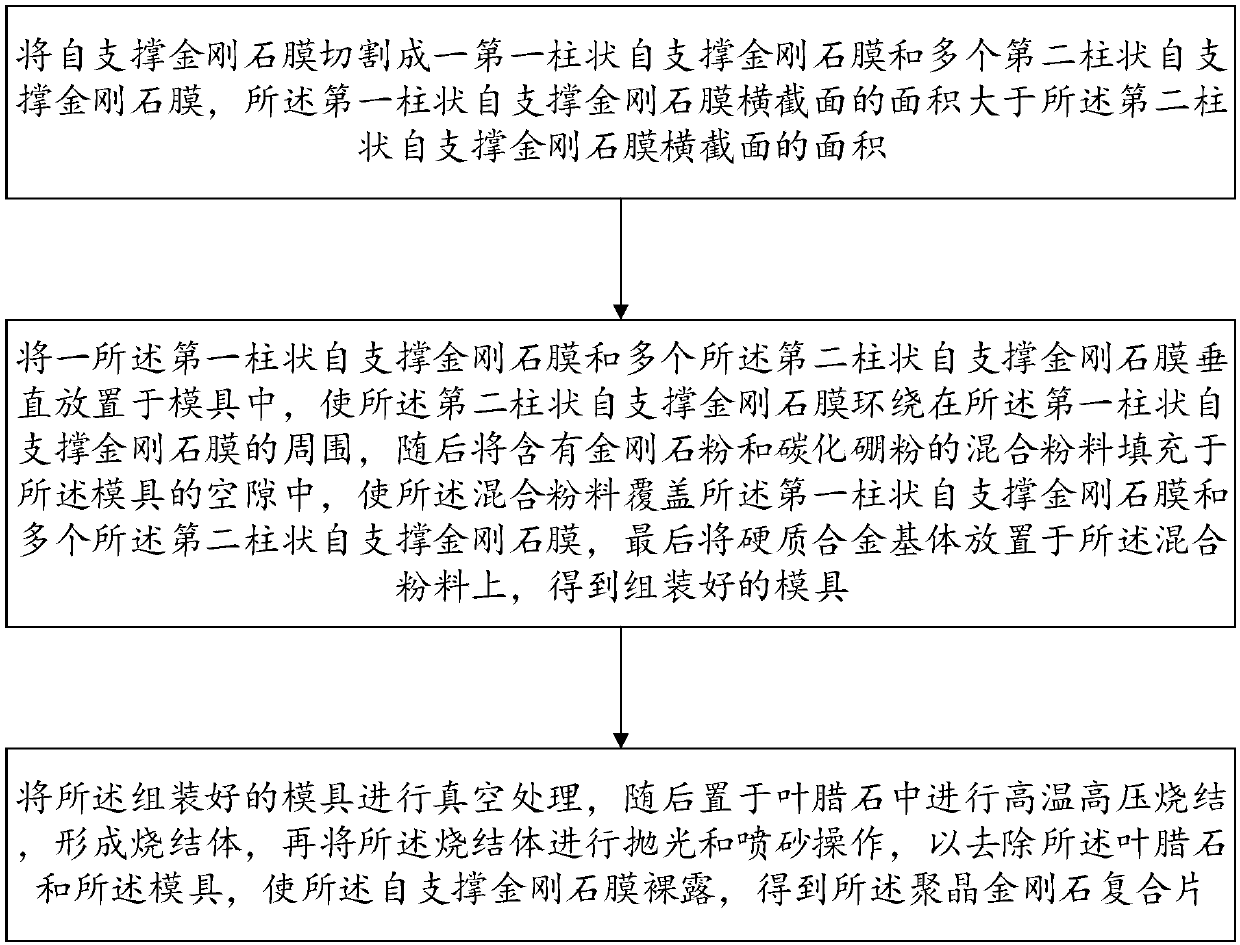

[0035] Please refer to image 3 , the preparation method of the polycrystalline diamond compact 100 according to the embodiment of the present invention provided by the embodiment of the present invention includes the following steps:

[0036] Step 1: cutting the self-supporting diamond film 21 into a first columnar self-supporting diamond film 211 and a plurality of second columnar self-supporting diamond films 212, the cross-sectional area of the first columnar self-supporting diamond film 211 is greater than that of the second columnar self-supporting diamond film The area of film 212 cross sections; Preferably, get commercially available self-supporting diamond film 21 or the self-supporting diamond film 21 prepared by chemical vapor deposition, it is cut into the first columnar self-supporting diamond film of different sizes to be used 211 and a plurality of second columnar self-supporting diamond films 212.

[0037] Step 2: Place a first columnar self-supporting dia...

Embodiment 1

[0043] A preparation method of a polycrystalline diamond compact, comprising the following steps:

[0044] Step 1: Using a laser cutting machine to cut the self-supporting diamond film 21 obtained by chemical vapor deposition into a first self-supporting diamond film cylinder 211 and a plurality of second self-supporting diamond film cylinders 212 . Wherein the first self-supporting diamond film cylinder 211 has a diameter of 4 mm and a height of 0.5 mm, and the second self-supporting diamond film cylinder has a diameter of 1 mm and a height of 0.5 mm.

[0045] Step 2: First mix the diamond micropowder and boron carbide powder evenly. Wherein the mass ratio of diamond powder and boron carbide powder is 3:1, the grain size of diamond powder is 5 μ m, and the grain size of boron carbide powder is 5 μ m; secondly, a first self-supporting diamond film cylinder 211 and a plurality of second A self-supporting diamond film cylinder 212 is placed vertically in a metallic molybdenum c...

Embodiment 2

[0048] A preparation method of a polycrystalline diamond compact, comprising the following steps:

[0049] Step 1: Using a laser cutting machine to cut the self-supporting diamond film 21 obtained by chemical vapor deposition into a first self-supporting diamond film cylinder 211 and a plurality of second self-supporting diamond film cylinders 212 . The first self-supporting diamond film cylinder 211 has a diameter of 6 mm and a height of 1.5 mm, and the second self-supporting diamond film cylinder has a diameter of 1.5 mm and a height of 1.5 mm.

[0050] Step 2: First mix the diamond micropowder and boron carbide powder evenly. Wherein the mass ratio of diamond powder and boron carbide powder is 6:1, the grain size of diamond powder is 35 μ m, and the grain size of boron carbide powder is 7 μ m; secondly, a first self-supporting diamond film cylinder 211 and a plurality of second A self-supporting diamond film cylinder 212 is placed vertically in a metallic molybdenum cup. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com