Methods for reducing one or more tobacco specific nitrosamines in tobacco material

A technology for nitrosamines and tobacco, which is applied in the directions of tobacco, analysis materials, and tobacco processing, and can solve the problems of deteriorating tobacco quality, insoluble matrix binding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

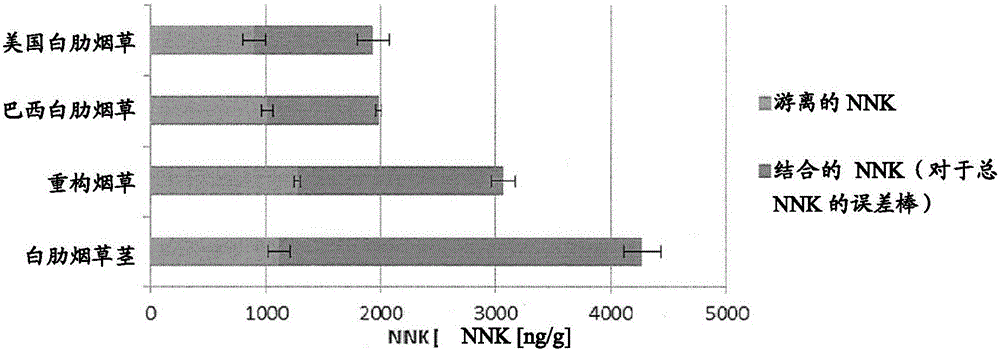

[0109] Method for analyzing free and bound NNK in tobacco

[0110] An aliquot (eg, about 750 mg) of the tobacco sample was extracted with about 30 mL of Tris-HCl buffer (50 mM; pH 7.4) by shaking at about room temperature for about 1 hour. Add internal standard (100ng / mLNNK-d 4 ). A sample (0.4 mL) of the extract was filtered using a 0.2 μΜ filter and analyzed for NNK content using ultra performance liquid chromatography-tandem mass spectrometry (UPLC-MS / MS). The sample concentrations calculated from these extract concentrations correspond to the "free NNK" concentrations in the samples. After processing the extraction mixture (eg, by heating to about 130° C. for about 4 hours) and filtering an aliquot of the extract, the NNK concentration was again measured by UPLC-MS / MS. From these values, the "total NNK" concentration in the sample can be calculated. The "bound NNK" concentration is the difference between the "total NNK" and "free NNK" concentrations.

[0111] An alter...

Embodiment 2

[0113] UPLC analysis

[0114] The column used was Waters Acquity BEHC18, 1.7 μm, 2.1×50 mm. The eluents used were: (A) ammonium bicarbonate (10 mM; adjusted to pH 9.8 with ammonia) + 2% (v / v) acetonitrile; (B) acetonitrile. The gradient used was 0 min-5%B; 0.5min-5%B; 3.3min-18.3%B. The flow rate used was 0.5 mL / min. The column temperature used was 50°C.

Embodiment 3

[0116] MS / MS methodology

[0117] The analysis was performed on a Waters TQ spectrometer using the following MRM transitions: NNK: 208.2 ◇ 122.2; dwell time 100 ms; NNK-d4: 212.2 ◇ 126.2; dwell time 100 ms; capillary voltage: 0.6 kV; cone voltage: 25 V; collision energy : 11eV; source temperature: 120°C; desolvation temperature: 400°C; desolvation gas flow: 800L / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com