Nitriding PVD composite coating and preparation method thereof

A composite coating and nitriding technology, applied in the field of high-performance die steel coating, can solve problems such as increasing the cost of coating preparation, and achieve the effects of improving interface stress concentration, improving bearing capacity, and improving film-matrix bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

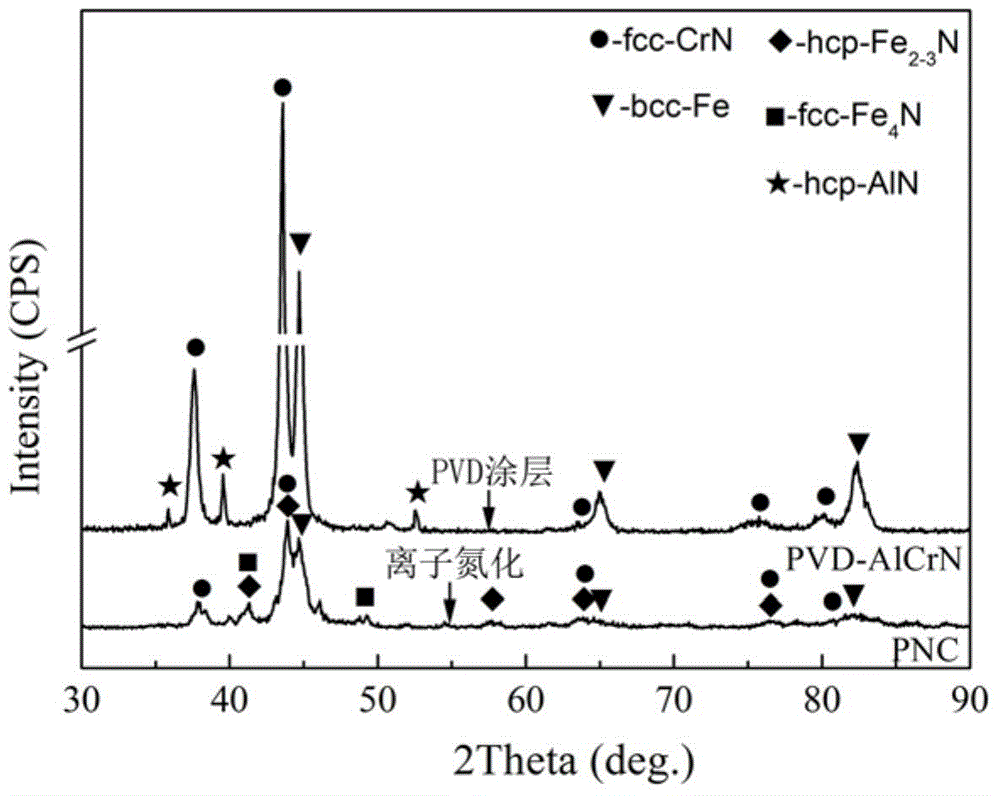

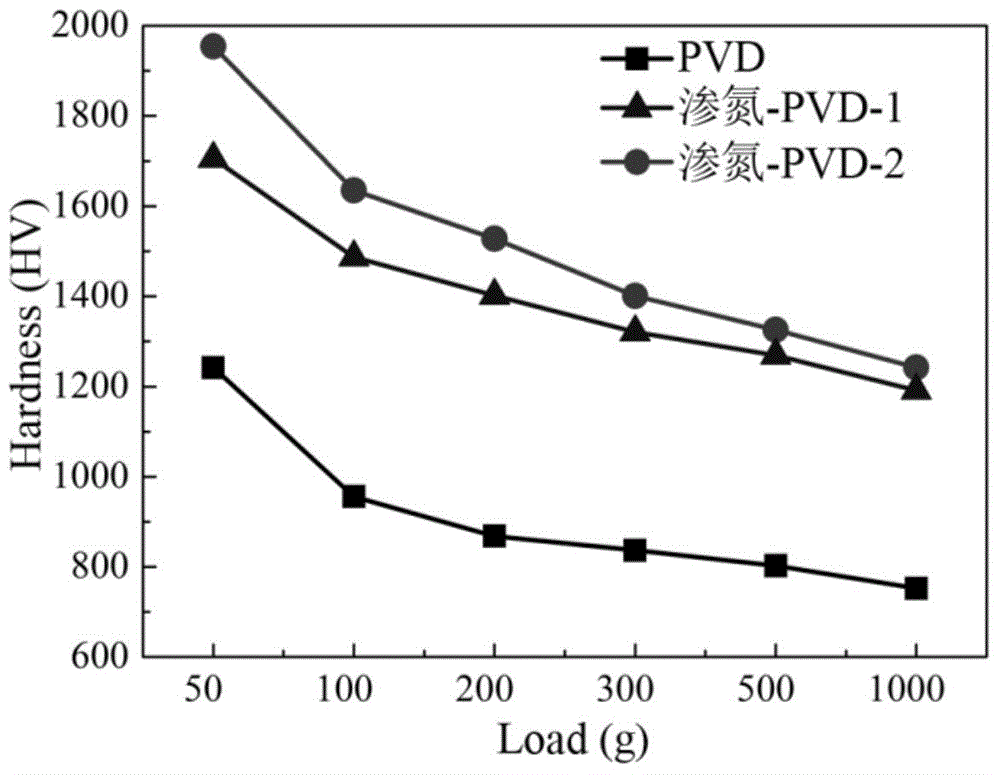

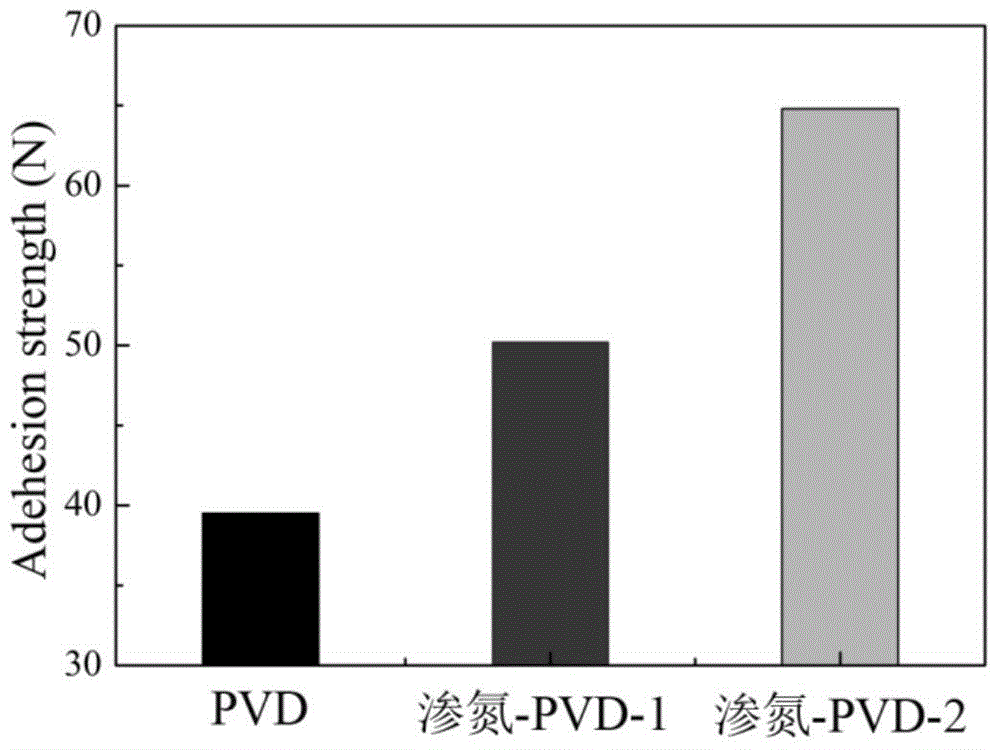

Embodiment 1

[0029] Mechanically polish the SKD 11 cold-working die steel samples purchased in the market to a surface roughness of ≤0.1 μm, then perform ultrasonic cleaning with acetone and absolute ethanol, then put them in alcohol and acetone, and use ultrasonic cleaning for 30 minutes, then Dry the cleaned samples with an air gun and place them on the substrate holder in the furnace cavity. Turn on the mechanical pump and the molecular pump to pump the background vacuum of the vacuum chamber to less than 1×10 -2 Pa, feed Ar gas and control the flow rate at 50-200sccm, the air pressure is less than 0.2Pa, the sample temperature is 300-500°C, the negative bias voltage is 1000V, and the bombardment time is 10-40min. After glow cleaning, adjust the vacuum to 0.1-5Pa, turn on the turret, Cr target and AlCr target, keep the sample bias at -30--200V, and turn on the N 2 , control the air pressure at 0-5Pa, keep the sample temperature at 300-500°C, target current at 50-100A, deposit for 1-3h,...

Embodiment 2

[0031] The SKD 11 cold work die steel samples purchased in the market were quenched for austenitization, and then tempered at high temperature to make the internal structure mainly tempered sorbite. Mechanically polish the sample to a surface roughness of ≤0.1 μm, then perform ultrasonic cleaning with acetone and absolute ethanol, put the cleaned workpiece into the frame of the ion nitriding furnace, and inject ammonia gas for glow heating. The vacuum degree of the vacuum chamber in the nitriding furnace is less than 1×10 -4 Pa, feed ammonia and control the flow rate at 100-200 sccm, feed acetone and control the flow rate at 20-50 sccm, and the furnace pressure is 5 × 10 -2 , the sample temperature is 520-590°C, the bias voltage is 400-800V, and the nitriding time is 3-9h, and the nitrided sample is prepared.

[0032] The nitrided sample is annealed in a salt bath furnace, the annealing temperature is controlled at 180-500°C and the annealing time is 1-14h. After the annealed...

Embodiment 3

[0034] The SKD 11 cold work die steel samples purchased in the market were quenched for austenitization, and then tempered at high temperature to make the internal structure mainly tempered sorbite. Mechanically polish the sample to a surface roughness of ≤0.1 μm, then perform ultrasonic cleaning with acetone and absolute ethanol, put the cleaned workpiece into the frame of the ion nitriding furnace, and inject ammonia gas for glow heating. The vacuum degree of the vacuum chamber in the nitriding furnace is less than 1×10 -4 Pa, feed ammonia and control the flow rate at 100-200 sccm, feed acetone and control the flow rate at 20-50 sccm, and the furnace pressure is 5 × 10 -2 , the sample temperature is 520-590°C, the negative bias voltage is 400-800V, and the nitriding time is 3-9h, and the nitrided sample is prepared.

[0035] The nitrided sample is annealed in a salt bath furnace, the annealing temperature is controlled at 180-500°C and the annealing time is 1-14h, the annea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com