Preparation method of Cr-doped DLC coating

A technology of coating and transition layer, applied in the field of preparation of DLC coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the Cr-doped DLC coating of the present embodiment comprises the following steps:

[0034] Step S1: Put the surface-treated tungsten-cobalt alloy substrate on the turret rod of the sputtering equipment cavity, and when the turret rotates as a whole, the turret rod rotates to ensure the uniformity of the coating;

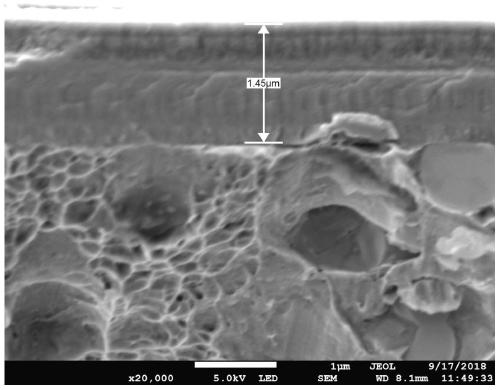

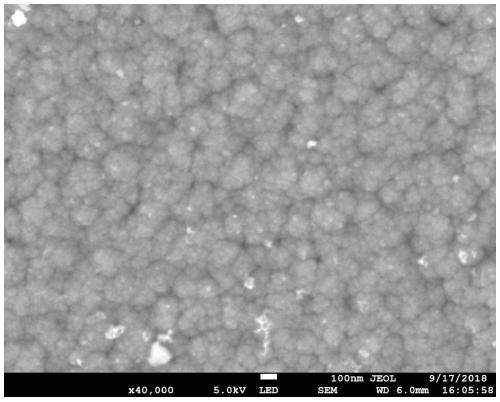

[0035] Step S2: Use the long-column Cr target as the doping source, the long-lived graphite target as the source of the carbon element, and the flat Cr target as the source of the doping Cr element, which is evenly distributed and installed on the inner wall of the furnace, using high-purity Ar As the main ionized gas, to ensure an effective glow discharge process; respectively use Cr layer as the bottom layer, CrN, CrN 2 , Cr+C as gradient transition layer, high-purity N 2 As a transition layer reaction gas, C 2 h 2 As DLC layer reaction gas, forming Cr, CrN, CrN 2 , Cr+C, α-C:H multi-layer film system coating;

[0036] Step S3:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com