High-quality fried walnut and processing and storage method thereof

A high-quality technology for walnut kernels, which is applied to the fields of high-quality fried walnut kernels and their processing and storage, can solve the problems of weak market competitiveness, poor quality and taste of fried walnut kernels, and achieves a taste without astringency, The effect of low broken kernel rate and uniform sugar coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

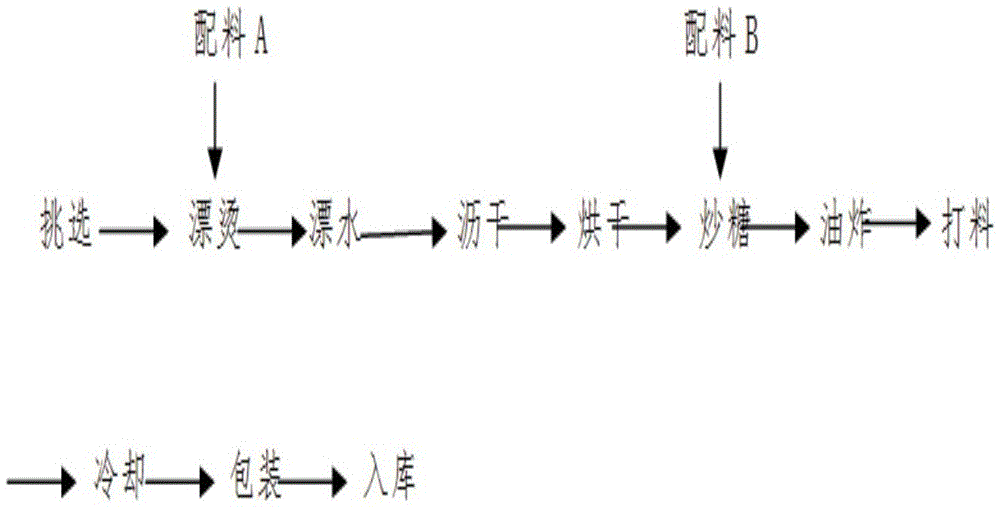

Method used

Image

Examples

Embodiment 1

[0040] 1. Storage of walnut kernel raw materials

[0041] Acceptance procedures for incoming walnut kernels:

[0042] After the walnut kernels come in, notify the quality control staff to check and accept them, and conduct sensory inspection and physical and chemical testing. Only those that pass the test can be put into storage. If there is any sensory defect, the raw materials must be selected to remove damaged fruits, black-spotted fruits and impurities. If the moisture is too damp, the raw materials need to be dried in the sun. When the moisture content of the nuts is ≤8%, if it needs to be stored until March of the next year, the moisture content must be controlled at ≤6.5% before storage.

[0043] Nitrogen-filled packaging process and operating procedures:

[0044] Conduct a trial run of the nitrogen charging equipment to check whether the equipment is operating normally.

[0045] Quantitatively weigh the qualified walnut kernels and carry out vacuum nitrogen-filled ...

Embodiment 2

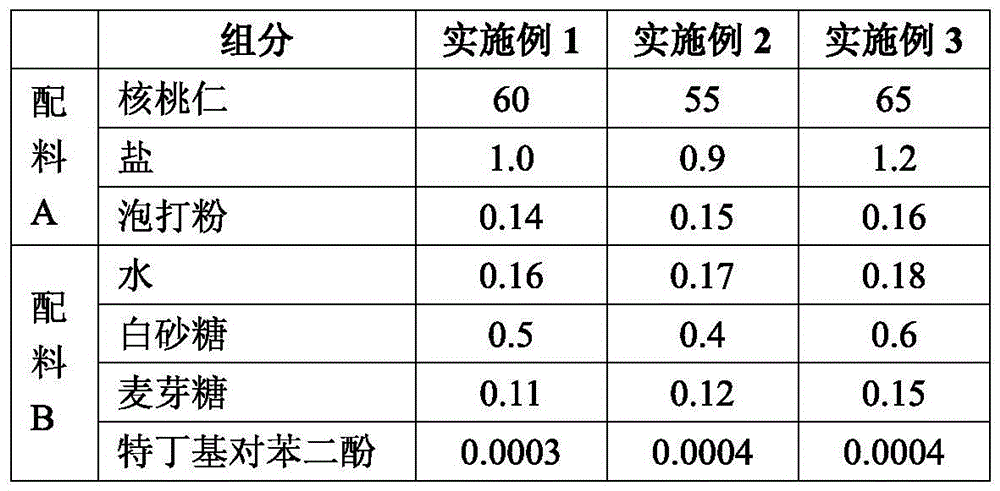

[0078] The process of this embodiment is substantially the same as that of Example 1, and the adjustment of its formula is shown in Table 1 for details.

Embodiment 3

[0080] The process of this embodiment is substantially the same as that of Example 1, and the adjustment of its formula is shown in Table 1 for details.

[0081] Table 2 The sensory index evaluation results and shelf life of the ten-person group

[0082]

[0083] Table 2 shows the sensory index evaluation results and shelf life of the ten-member panel of fried walnut kernels prepared in Examples 1 to 3, all of which meet the requirements of the national standard "GB / T22165-2008 General Rules for Roasted Nuts and Seeds and Seeds".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com