A three-phase separation device used under pressure

A three-phase separation and condition technology, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve problems such as pressure instability, and achieve the effects of stable pressure, improved stability, and increased integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

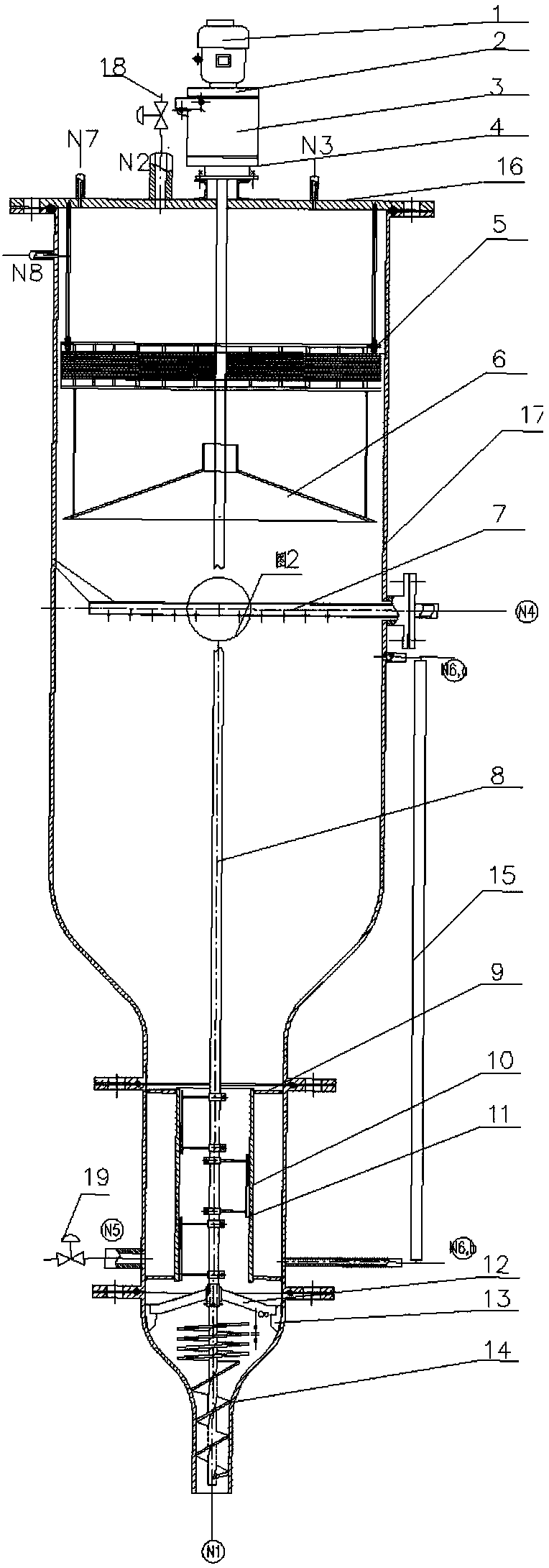

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

[0026] see figure 1 , the present invention is made up of motor 1, cylinder body 17 and each functional area in cylinder body, and cylinder body upper part is sealing end cap 16, and end cap and cylinder body use flange connection. The middle spray pipe 7 is the liquid inlet containing gas-solid impurities. The main functional area includes three parts: the upper part is the gas-liquid separation part, including the separation umbrella 6, the wire mesh demister 5, the gas outlet N2, the pressure gauge interface N7, Safety valve outlet N3, pressure supplement system interface N8, gas phase outlet regulating valve 18; the middle part is the liquid-solid separation part, mainly including metal filter element 10, mechanical scraper 11, liquid phase outlet N5, liquid level gauge 15, liquid phase outlet adjustment The valve 19, the cylinder of the liquid-solid separation pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com