Condensation-type gas-liquid separation apparatus

A gas-liquid separation device and condensing technology, which is applied in the direction of separation method, dispersed particle separation, steam condensation, etc., can solve the problems that cannot meet the technical conditions of the wet complexation absorption method denitrification process, so as to improve the efficiency of gas-liquid separation and improve The effect of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

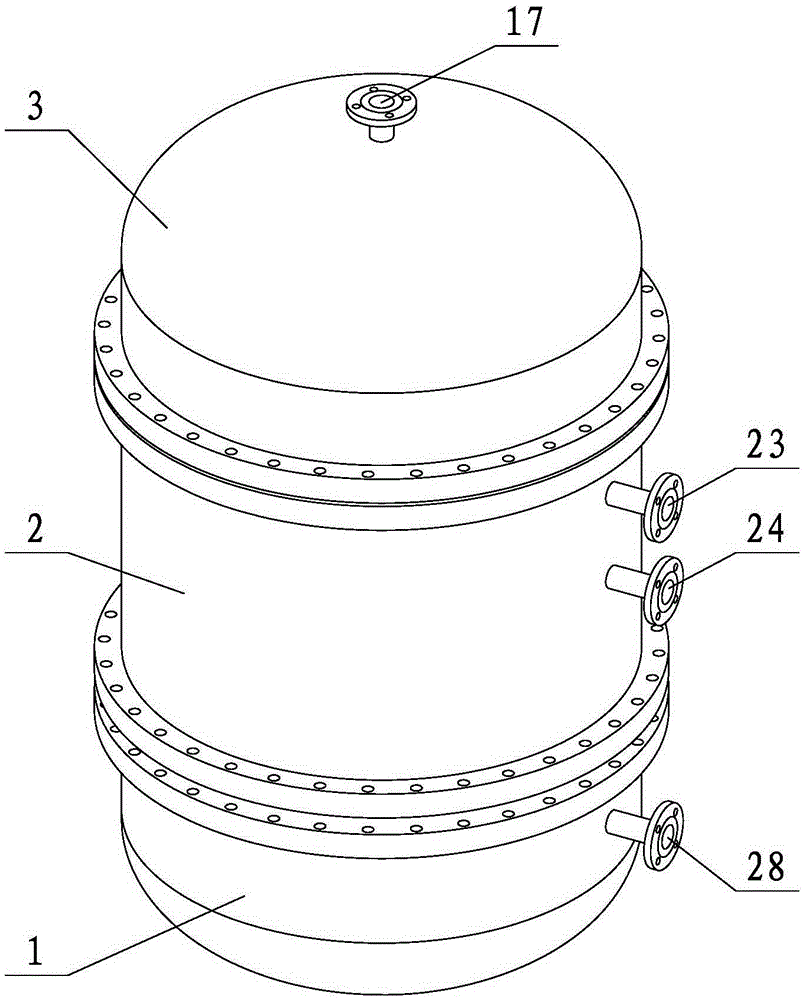

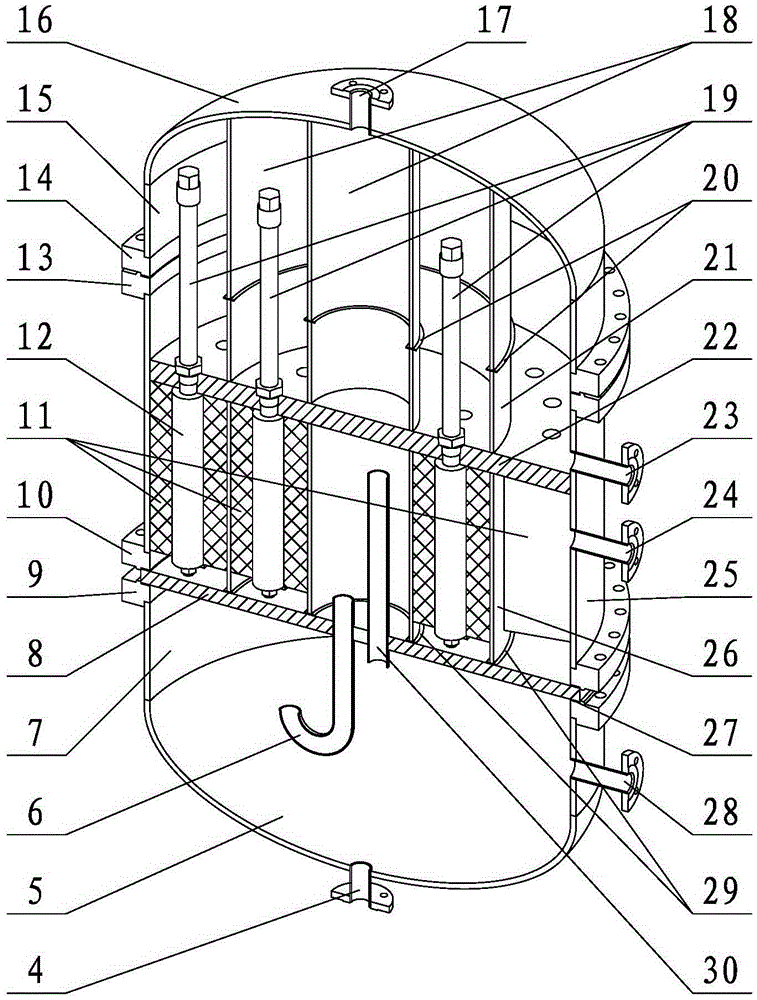

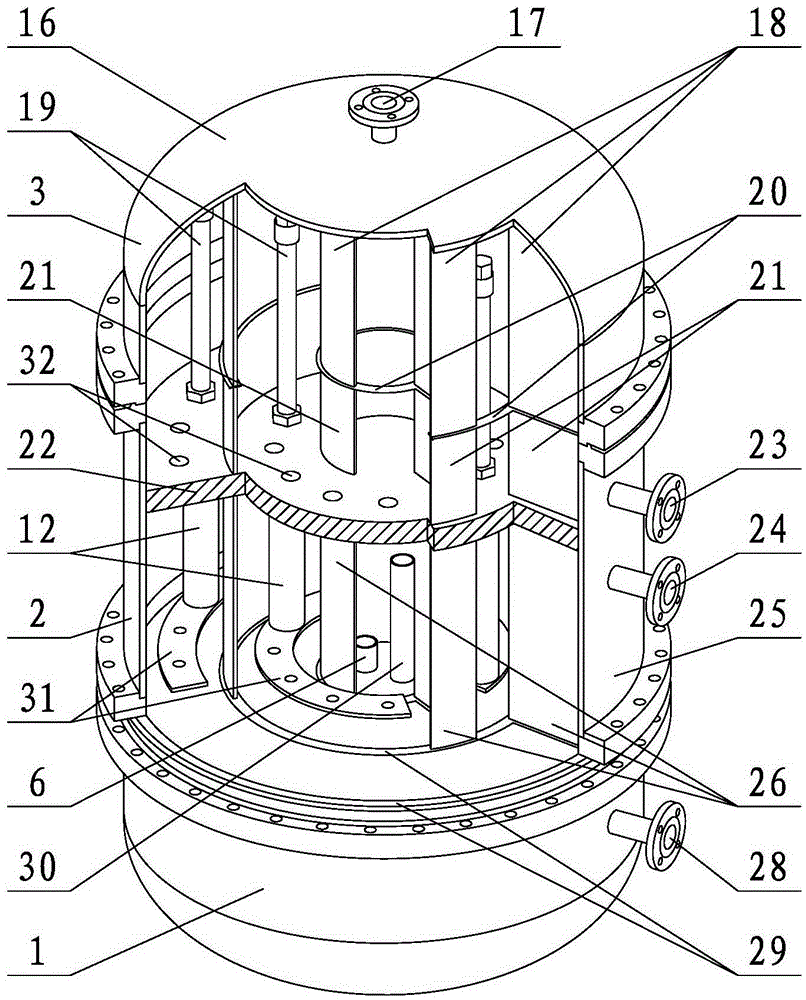

[0034] The present invention is further described below in conjunction with accompanying drawing.

[0035] refer to figure 1 , figure 2 with image 3 , a condensing type gas-liquid separation device is mainly composed of a lower head part 1, a tank body part 2, an upper head part 3, a diaphragm part, a flange pad one 27, a flange pad two 29, a flange pad Three 20, wire mesh bar part 11, fixed plate part 31, heat pipe heat exchanger part 19 are formed. The upper head part 3 is installed on the upper end of the tank part 2, the diaphragm part is installed on the lower end of the tank part 2, the lower head part 1 is installed on the lower end of the diaphragm part, and there is a porous plate 22 in the middle of the tank part 2, The porous plate 22 divides the inner cavity of the tank body part 2 into two parts. The inner cavity from the upper end surface of the porous plate 22 to the inner surface of the upper head part 3 is the upper cavity of the tank body, and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com