Novel marsh gas pretreatment device

A pretreatment device and biogas technology, applied in gas treatment, gas fuel, separation methods, etc., can solve the problems of large total volume, and achieve the effects of convenient transportation, simplified overall setting and improved effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

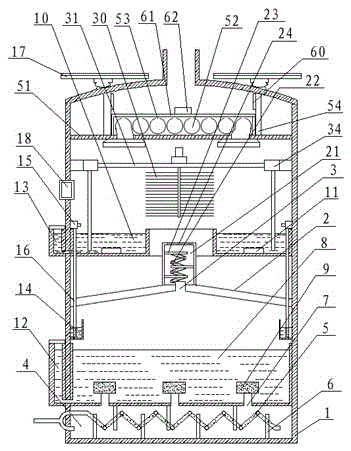

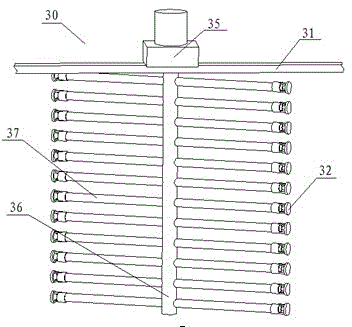

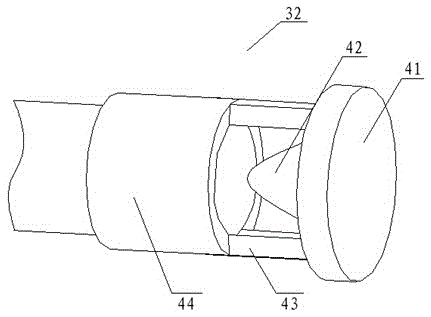

[0034] see Figure 1 to Figure 6 , the present invention provides a new type of biogas pretreatment device, as a primary filter device in the biogas purification pretreatment process, including a filter tank, the filter tank is connected with a biogas collection tank, and biogas is collected from the biogas collection tank, usually with The fan pumps out the biogas in the biogas collection tank and puts it into the filter tank. The filter tank includes a tank body 1, which is provided with a partition 2 that separates the tank body 1 from top to bottom, and an opening 3 is left in the middle of the partition 2; The partition 2 is inclined to both sides along the opening 3, forming an inverted "V" shape. The upper surface of the partition 2 is an arc surface protruding upwards in the middle. Diversion grooves are arranged on both sides of the partition 2, and a deceleration chamber is arranged on the partition 2. 21. The deceleration chamber 21 is a chamber for biogas to pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com