Automatic assembly line for radar products

An automatic assembly and automatic technology, applied in the direction of assembly machines, other manufacturing equipment/tools, metal processing equipment, etc., can solve problems such as the inability to achieve the production quantity and quality, affecting the assembly efficiency of radar products, and the unreasonable arrangement of equipment. Achieve the effect of guaranteeing the quality of radar products, improving the confidence of traceability support capability, saving time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

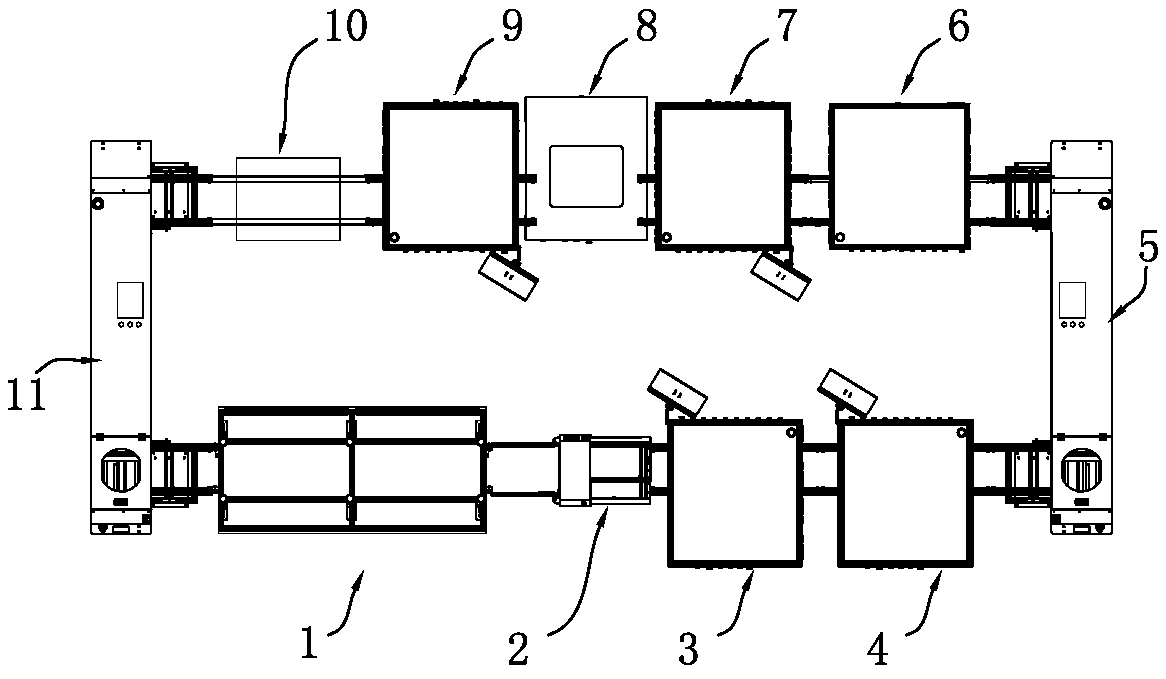

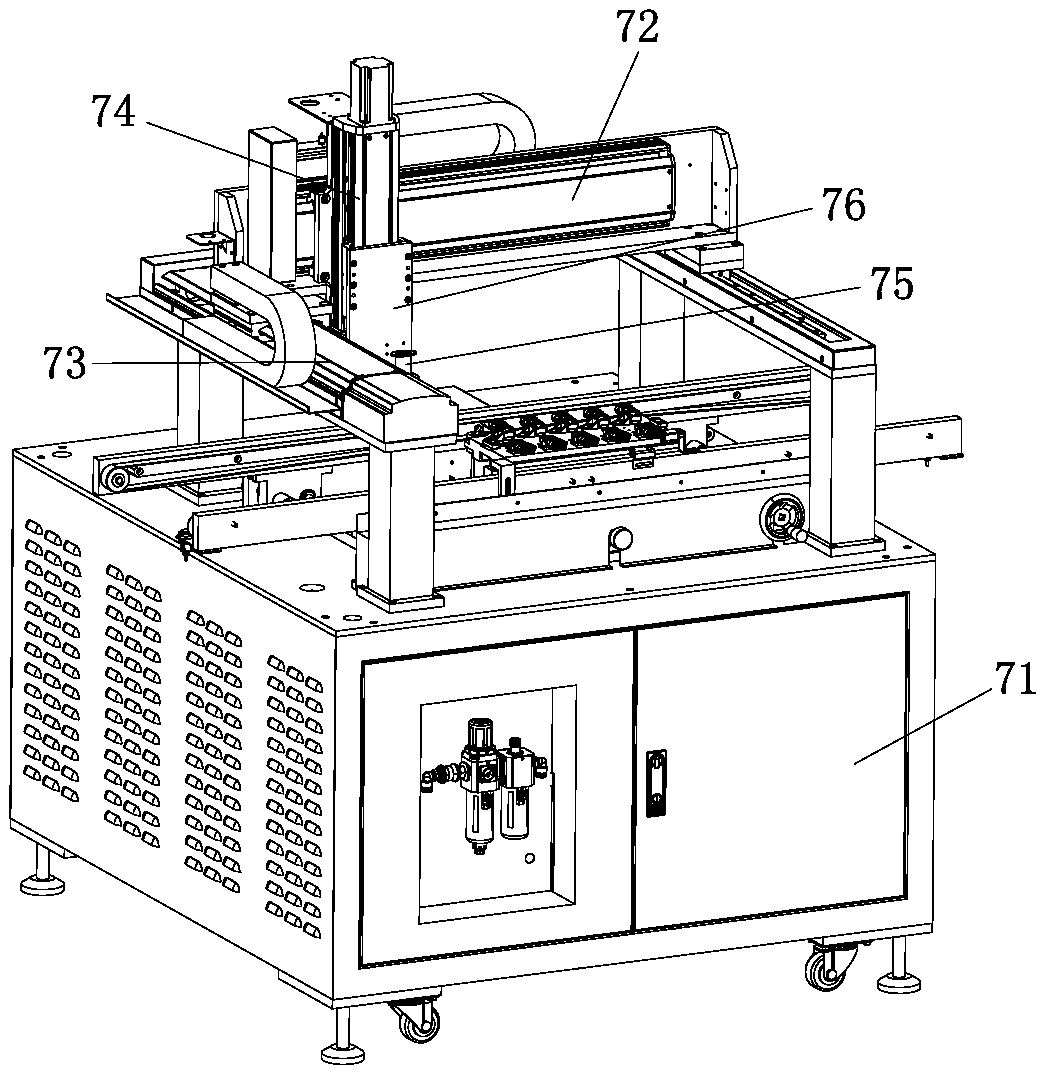

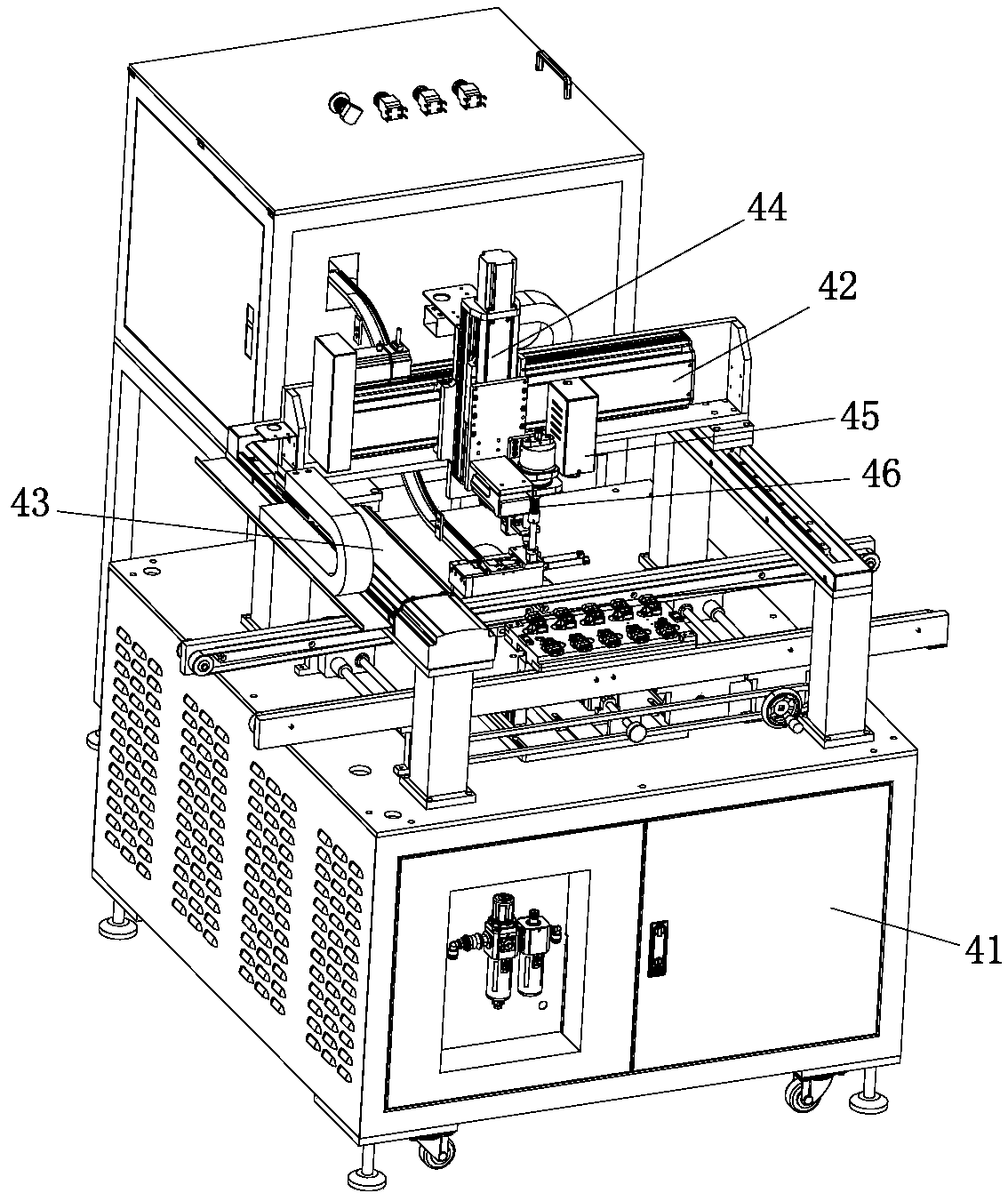

[0013] see figure 1 , figure 2 and image 3 , an automatic assembly line for radar products provided in this embodiment, which includes a workbench 1, a folding connection table 2, an automatic code reading point solder paste machine 3, an automatic laser welding machine 4, a first translation machine 5, and an automatic static test machine 6, automatic double-head dispensing machine 7, automatic vacuum defoaming machine 8, automatic cap suction combination machine 9, buffer connection table 10, second translation machine 11 and product traceability system, and the product traceability system is respectively related to the Workbench 1, folding connection table 2, automatic code reading point solder paste machine 3, automatic laser welding machine 4, first translation machine 5, automatic static testing machine 6, automatic double-head glue dispensing machine 7, automatic vacuum defoaming machine 8. The automatic cap suction assembly machine 9 is connected to the buffer conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com