Production process of monolithic refractories and lining bricks for zinc oxide rotary kiln

A refractory material and production process technology, applied in the field of unshaped refractory material for zinc oxide rotary kiln and its brick making process, can solve the problems of large heat loss, high energy consumption, unfavorable market competition, etc., and achieve enhanced integrity and process flow. Simple, energy- and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

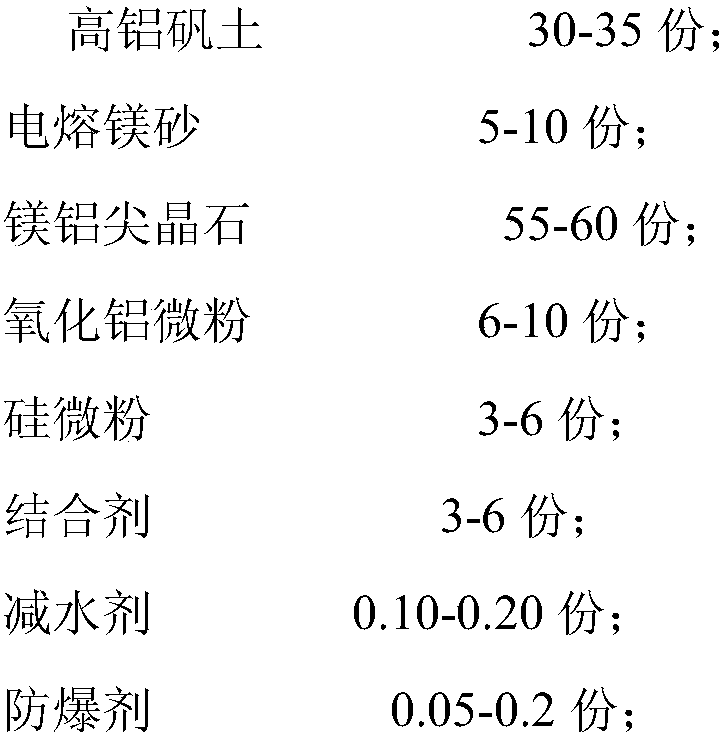

[0054] The monolithic refractory material for zinc oxide rotary kiln described in this embodiment contains the components and the parts by mass of various components as follows:

[0055] 35 parts of high alumina bauxite;

[0056] 10 parts of fused magnesia;

[0057] 60 parts of magnesium aluminum spinel;

[0058] 10 parts of alumina micropowder;

[0059] 6 parts of silica powder;

[0060] 6 parts of pure calcium aluminate cement;

[0061] Sodium hexametaphosphate 0.20 parts;

[0062] Explosion-proof fiber 0.2 parts.

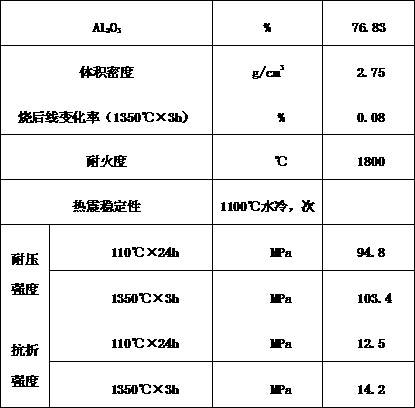

[0063] After testing, the technical parameter of the monolithic refractory material for the zinc oxide rotary kiln of the present invention is

[0064]

Embodiment 2

[0066] The monolithic refractory material for zinc oxide rotary kiln described in this embodiment contains the components and the parts by mass of various components as follows:

[0067] 32 parts of high alumina bauxite;

[0068] 7 parts of fused magnesia;

[0069] 58 parts of magnesium aluminum spinel;

[0070] 8 parts of alumina fine powder;

[0071] 5 parts of silica powder;

[0072] 4 parts of pure calcium aluminate cement;

[0073] Sodium hexametaphosphate 0.16 parts;

[0074] Explosion-proof fiber 0.15 parts.

[0075] The remaining components, proportioning ratio and production process of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0077] The monolithic refractory material for zinc oxide rotary kiln described in this embodiment contains the components and the parts by mass of various components as follows:

[0078] 30 parts of high alumina bauxite;

[0079] 5 parts of fused magnesia;

[0080] 55 parts of magnesium aluminum spinel;

[0081] 6 parts of alumina micropowder;

[0082] 3 parts of silica powder;

[0083] 3 parts of pure calcium aluminate cement;

[0084] Sodium hexametaphosphate 0.10 parts;

[0085] Explosion-proof fiber 0.05 parts.

[0086] The remaining components, proportioning ratio and production process of this embodiment are the same as those of Embodiment 1 or 2, and will not be repeated here.

[0087] The raw materials used in the invention are mainly magnesia-aluminum spinel, high-quality high-alumina bauxite, and fused magnesia, and a certain amount of binder, water-reducing agent and explosion-proof agent are added to make the lining brick with good energy-saving effect.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com