PDLC composition with wide viewing angle

A composition, wide viewing angle technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of reduced film transmittance, viewing angle problems, and the degree of refractive index matching is not as good as the vertical direction, etc., to achieve good viewing angle characteristics, improve film The effect of reducing the surface transmittance and improving the customer experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A PDLC composition with a wide viewing angle in this embodiment, the components in the PDLC composition and their weight percentages are as follows:

[0065] Light curing material 49.0%,

[0066] Liquid crystal material 50.0%,

[0067] Photoinitiator 1.0%.

[0068] The components of the photocurable material of this embodiment and the weight percentage of the components in the PDLC composition are specifically:

[0069] Photocurable prepolymer 24.0%,

[0070] Thinner 22.0%,

[0071] Reactive Liquid Crystal 3.0%.

[0072] The photocuring prepolymer chooses CN704 from Sartomer Company. CN704 is a monofunctional acrylic polyester, which can improve the adhesion. In this formula, it is used as the main component to provide the strength of the polymer.

[0073] The diluent is hydroxypropyl acrylate.

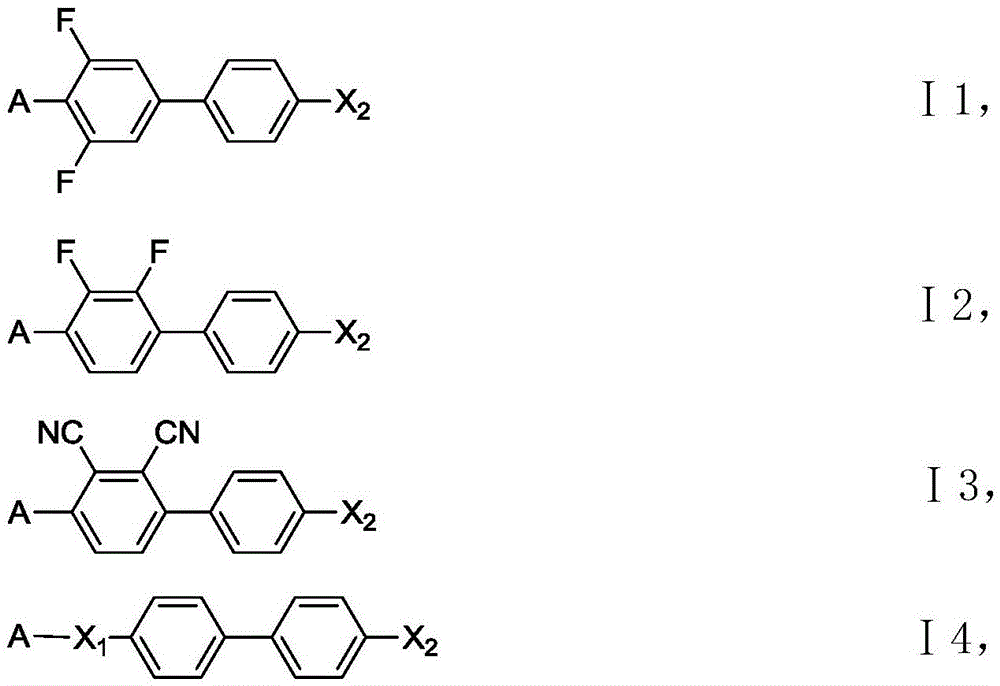

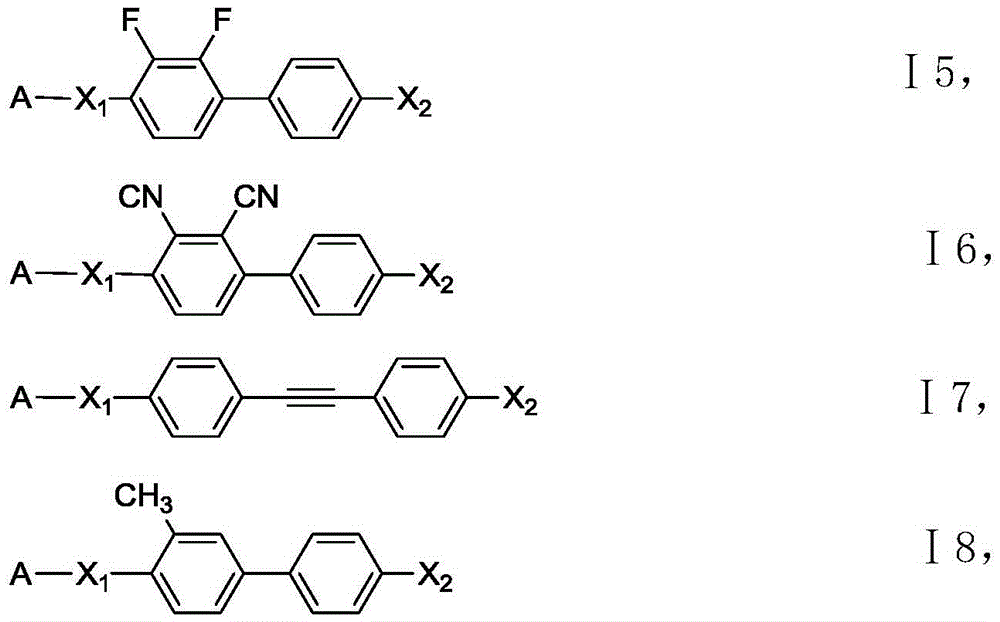

[0074] The structural formula of the reactive liquid crystal and its weight percentage in the PDLC composition are specifically:

[0075]

[0076] The liquid crystal...

Embodiment 2

[0080] A PDLC composition with a wide viewing angle in this embodiment, the components in the PDLC composition and their weight percentages are as follows:

[0081] Light curing material 48.0%,

[0082] Liquid crystal material 50.0%,

[0083] Photoinitiator 2.0%;

[0084] The components of the photocurable material of this embodiment and the weight percentage of the components in the PDLC composition are specifically:

[0085] Photocurable prepolymer 24.0%,

[0086] Thinner 21.0%,

[0087] Reactive Liquid Crystal 3.0%.

[0088] The photocuring prepolymer is selected from Sartomer's acrylic polyurethane CN966J75NS. CN966J75NS is a bifunctional aliphatic urethane acrylate polymer with high strength and good toughness. In this formula, it mainly provides polymer strength and toughness.

[0089] The diluent is lauryl acrylate.

[0090] The structural formula of the reactive liquid crystal and its weight percentage in the PDLC composition are specifically:

[0091]

[00...

Embodiment 3

[0096] A PDLC composition with a wide viewing angle in this embodiment, the components in the PDLC composition and their weight percentages are as follows:

[0097] Light curing material 44.0%,

[0098] Liquid crystal material 55.0%,

[0099] Photoinitiator 1.0%;

[0100] The components of the photocurable material of this embodiment and the weight percentage of the components in the PDLC composition are specifically:

[0101] Photocurable prepolymer 17.0%,

[0102] Thinner 21.0%,

[0103] Reactive Liquid Crystal 4.0%.

[0104] The light-curing prepolymer chooses acrylic polyurethane UV65 from Shanghai Kuer Industrial Co., Ltd. UV65 has the characteristics of high strength and good toughness. In this formula, it mainly provides polymer strength and toughness.

[0105] The components of the diluent and the weight percentage of the components in the PDLC composition are specifically:

[0106]

[0107] The structural formula of the reactive liquid crystal and its weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com