High-temperature resistant slag cleaning and fishing device

A technology of high temperature resistance and slag removal, applied in coating, metal material coating process, hot dip plating process, etc., can solve the problems of only slag fishing, large space occupation, low application temperature, etc., and achieves high work efficiency, Easy maintenance and installation, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

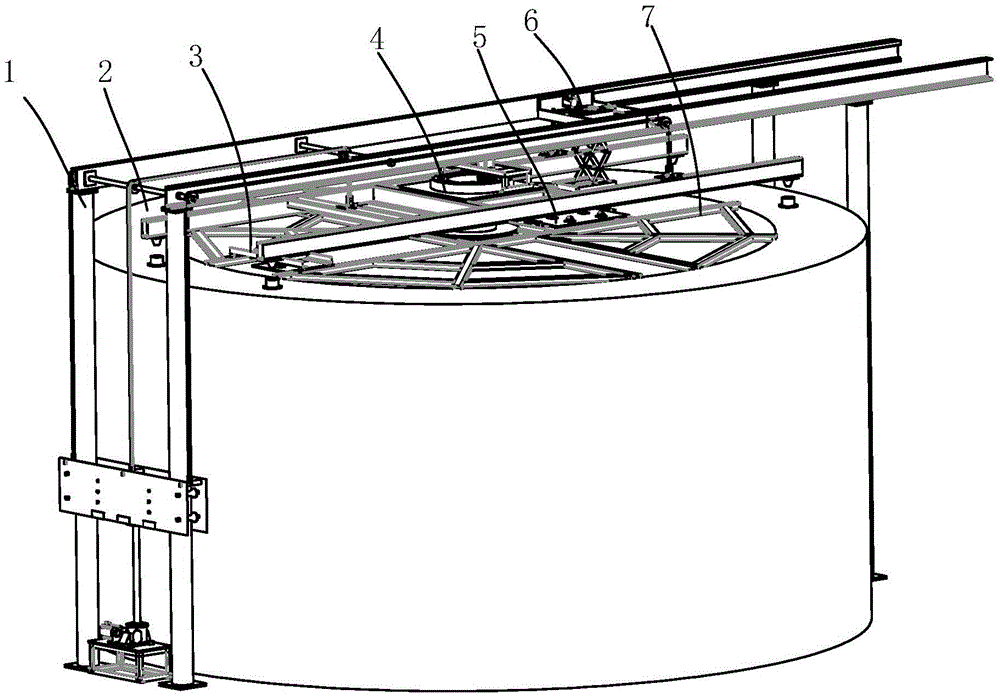

[0027] exist figure 1In the schematic diagram of the high-temperature slag cleaning and slag removal device shown, the gantry type self-positioning lifting device 1 is set above the heat preservation and heating pot 2, and the center top of the multifunctional rotary pot cover 7 for cleaning and scraping is fixed on the inner ring of the rotary support 4, and the rotary support The outer ring is fixed on the positioning rectangular frame of the tapered positioning pin on the gantry type self-positioning lifting device, the self-cleaning scraping bucket 5 and the rotary stirring slag cleaning device 3 are respectively installed on the pot cover, and the two-degree-of-freedom slag dumping manipulator 6 is fixed On the beams of the aforementioned gantry.

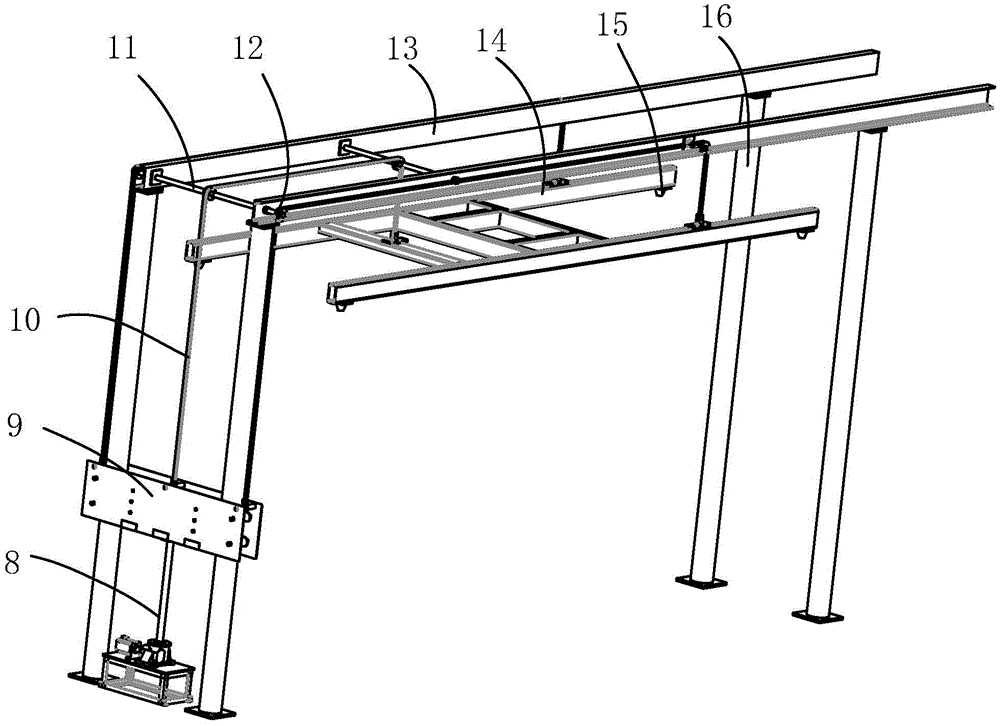

[0028] Such as figure 2 As mentioned above, the gantry frame in the gantry type self-positioning lifting device is formed by connecting four pillars 16 and two beams 13, and the counterweight 9 is installed on the two pillars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com