Preparation method of large-size Cu(111) monocrystal copper foil and ultra-large-size monocrystal graphene

A single-crystal graphene, ultra-large-size technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve problems such as reducing grain boundary density, achieve reduced production costs, good application prospects, and fewer defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

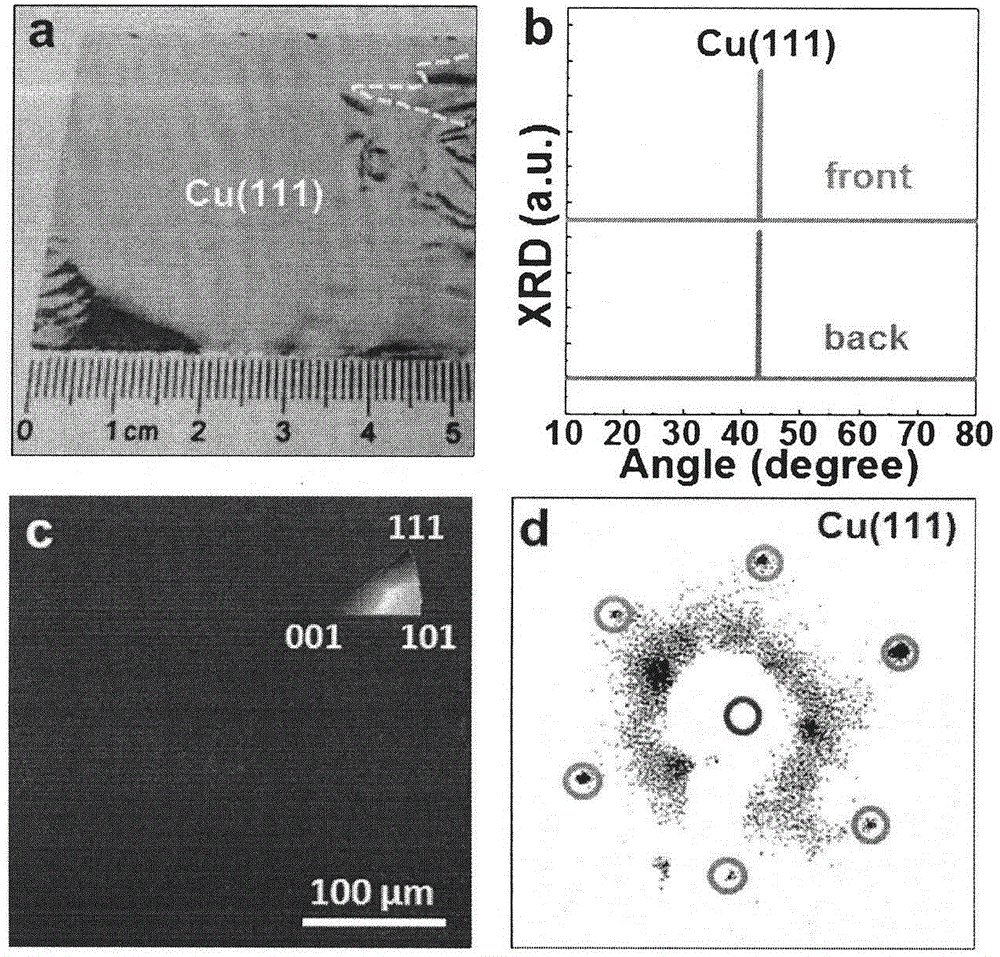

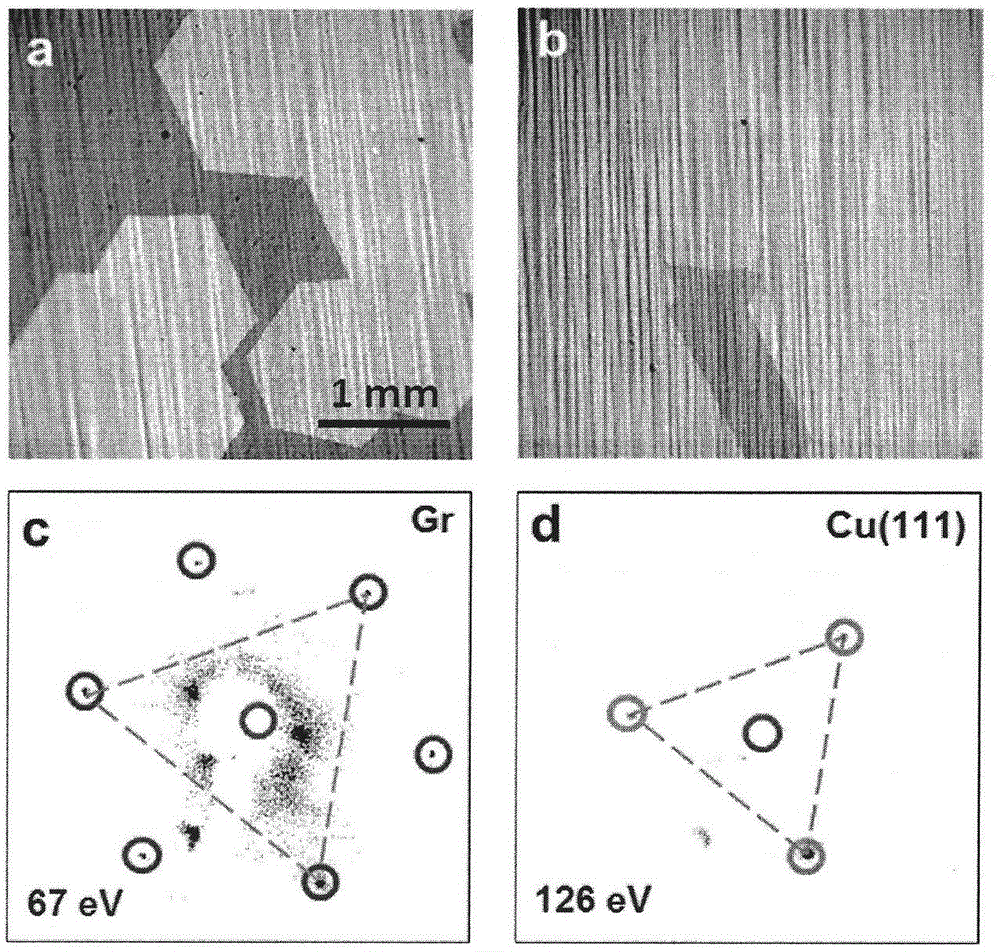

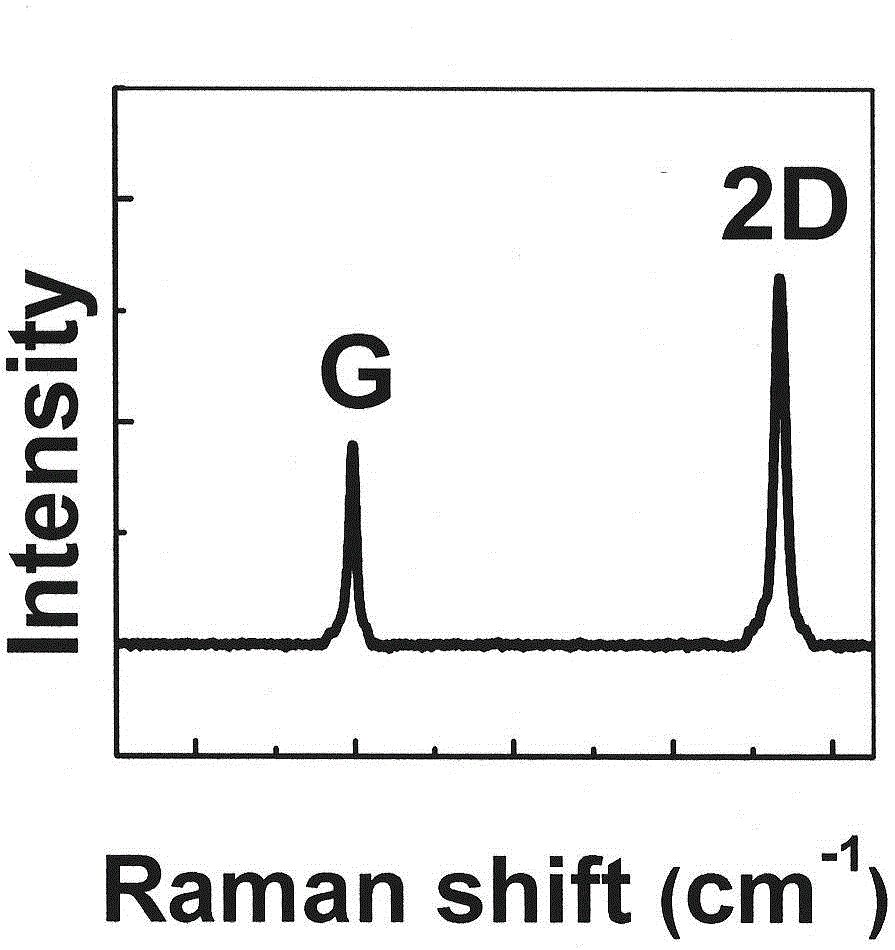

[0018] Embodiment 1: A method for annealing doped polycrystalline copper foil to prepare single crystal Cu(111) and super-large single crystal graphene

[0019] 1. Put the polycrystalline copper foil doped with metal elements into the chemical vapor deposition equipment, pass in the inert gas, the flow rate is more than 300 sccm, and the working pressure is normal pressure (that is, one atmosphere or about 1×10 5 Pa), and then start to heat up, and the heating process lasts for 50 to 70 minutes;

[0020] 2. When the temperature rises to 800~1100℃, H 2 Gas, H 2 The flow rate is 2-500sccm, the inert gas flow rate remains unchanged, and the annealing process is carried out, and the annealing duration is 5-180min;

[0021] 3. After the annealing is over, start to introduce CH 4 Mixed gas with inert gas (CH 4 The content is 200~20000ppm), the mixed gas flow rate is 0.2~50sccm, and the H 2 The flow rate is 0.2-50 sccm, the inert gas flow rate remains unchanged, and the working ...

Embodiment approach 2

[0069] Embodiment 2: A method of annealing doped polycrystalline copper to prepare single-crystal copper foil and super-large-sized single-crystal graphene. Influence of oxygen in the heating process:

[0070]Test 1: A method of annealing doped polycrystalline copper to prepare single-crystal copper foil and super-large-size single-crystal graphene in this test is carried out according to the following steps:

[0071] 1. Put the polycrystalline copper foil doped with metal elements on the crucible substrate, put it into the chemical vapor deposition equipment, and pass Ar and H 2 Gas, Ar flow rate is 500sccm, H 2 The flow rate is 20sccm, and the working pressure is 1×10 5 Pa, then start to heat up, and the heating process lasts for 60 minutes;

[0072] 2. When the temperature rises to 1000°C, H 2 , the Ar flow rate remains constant, and the annealing process is carried out, and the annealing duration is 60min;

[0073] 3. After the annealing is over, start to introduce CH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com