Rapid hydrogen peroxide test paper and preparation method thereof

A technology for detecting test paper and hydrogen peroxide, which is applied in the direction of analyzing materials through chemical reactions and observing the influence of chemical indicators on materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

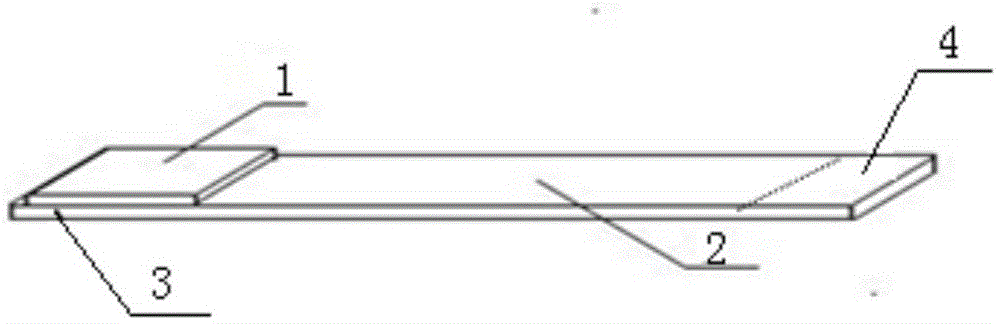

Image

Examples

Embodiment 1

[0027] Step 1. Antioxidant system preparation: Weigh 1.0000g tea polyphenols and 0.2000g vitamin c, dissolve in 100mL distilled water, then add 1.5000g sodium thiosulfate, stir to dissolve and set aside;

[0028] Step 2. Enzyme protection system preparation: Weigh 2.5000g sucrose and dissolve in 100mL distilled water, then add 1.0000g polyethylene glycol and 0.8000g bovine serum albumin, heat and dissolve on an electric furnace, cool, and set aside;

[0029] Step 3. Chromogen preparation: Weigh 1.0000g of tetramethylbenzidine, add 50mL of distilled water to dissolve, then add 20mg of horseradish peroxidase to dissolve, set aside;

[0030] Step 4. Mix the prepared antioxidant system, enzyme protection system and color developer, and stir evenly to obtain the test paper soaking solution;

[0031] Step 5. Pour the soaking liquid of the test paper into the glass dish, slowly immerse the cut filter paper (pH test paper base paper, the specification is 15*30cm) into the soaking liqu...

Embodiment 2

[0036] Step 1. Antioxidant system preparation: Weigh 1.0000g tea polyphenols and 0.2000g vitamin c, dissolve in 100mL distilled water, then add 1.0000g sodium thiosulfate, stir to dissolve and set aside;

[0037] Step 2. Enzyme protection system preparation: Weigh 2.5000g sucrose and dissolve in 100mL distilled water, then add 1.0000g polyethylene glycol and 0.5000g bovine serum albumin, heat and dissolve on an electric furnace, cool, and set aside;

[0038] Step 3. Chromogen preparation: Weigh 1.0000g of tetramethylbenzidine, add 50mL of distilled water to dissolve, then add 20mg of horseradish peroxidase to dissolve, set aside;

[0039] Step 4. Mix the prepared antioxidant system, enzyme protection system and color developer, and stir evenly to obtain the test paper soaking solution;

[0040] Step 5. Pour the soaking liquid of the test paper into the glass dish, slowly immerse the cut filter paper (pH test paper base paper, the specification is 15*30cm) into the soaking liqu...

Embodiment 3

[0044] Step 1. Antioxidant system preparation: Weigh 1.0000g tea polyphenols and 0.1000g vitamin c, dissolve in 100mL distilled water, then add 2.0000g sodium thiosulfate, stir to dissolve and set aside;

[0045] Step 2. Enzyme protection system preparation: Weigh 2.5000g sucrose and dissolve in 100mL distilled water, then add 0.5000g polyethylene glycol and 1.0000g bovine serum albumin, heat and dissolve on an electric furnace, cool, and set aside;

[0046]Step 3. Chromogen preparation: Weigh 1.0000g of tetramethylbenzidine, add 50mL of distilled water to dissolve, then add 40mg of horseradish peroxidase to dissolve, set aside;

[0047] Step 4. Mix the prepared antioxidant system, enzyme protection system and color developer, and stir evenly to obtain the test paper soaking solution;

[0048] Step 5. Pour the soaking liquid of the test paper into the glass dish, slowly immerse the cut filter paper (pH test paper base paper, the specification is 15*30cm) into the soaking liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com