Transformer shielding layer design method for flyback switching power supply

A switching power supply and design method technology, applied in the manufacture of inductors/transformers/magnets, preventing/reducing unwanted electric/magnetic influences, circuits, etc., can solve power supply products that are difficult to meet EMC standards, electronic load interference, EMI, etc. problem, to achieve the effect of common mode noise suppression, increase product cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

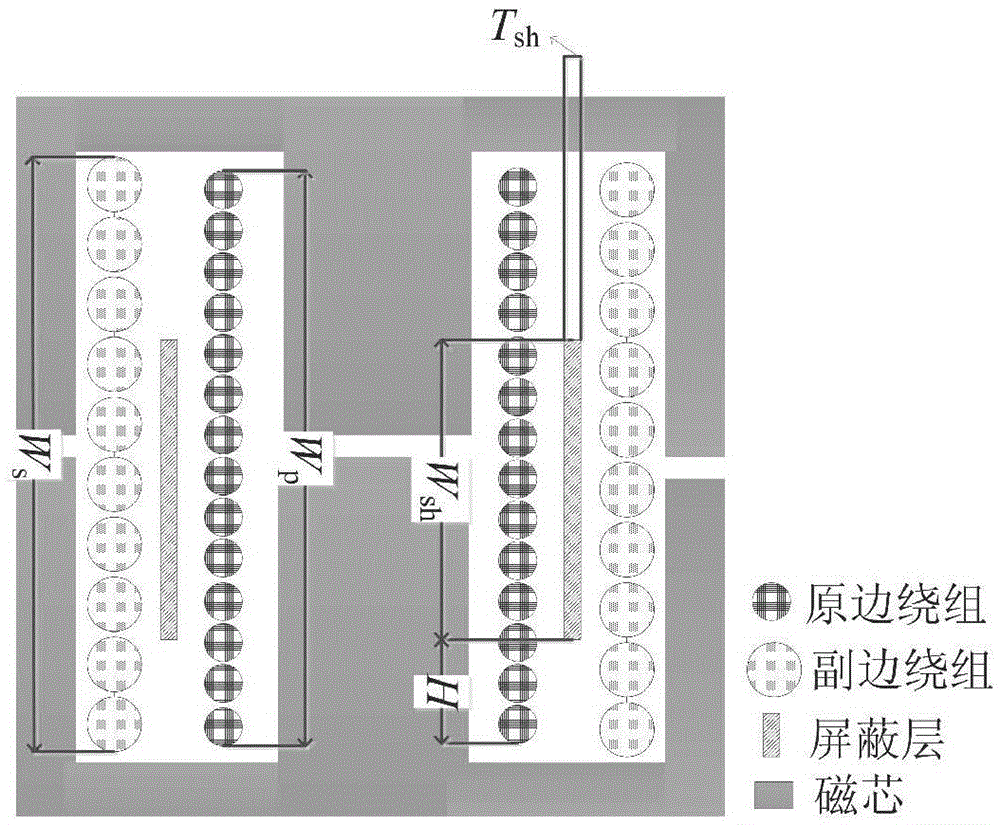

[0038] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

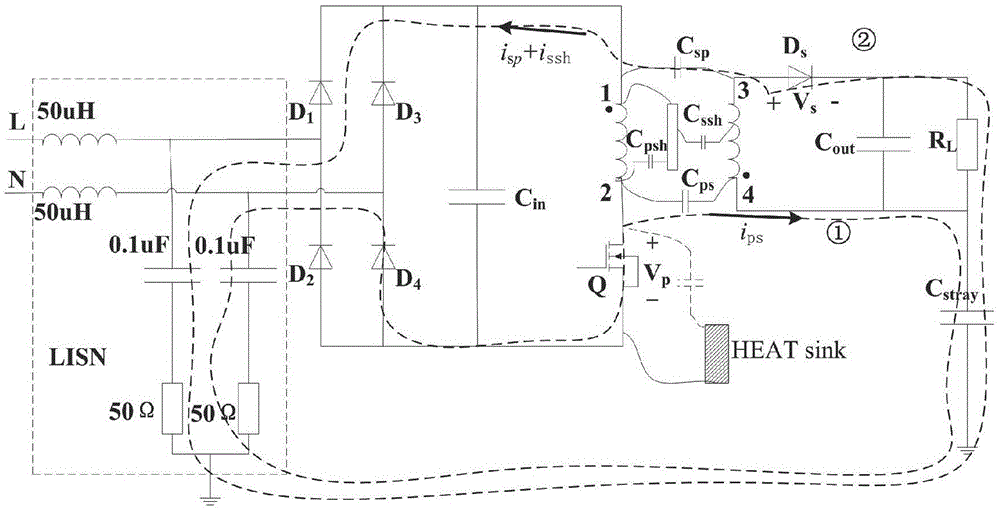

[0039] The transformer shielding layer design method of the flyback switching power supply of the present invention uses finite element analysis software to simulate the structural capacitance between the original and secondary windings and the structural capacitance between the secondary winding and the shielding layer under different shielding layer widths, and then Use the common-mode current evaluation formula to calculate the shielding layer width when the common-mode current is minimum, including the following steps:

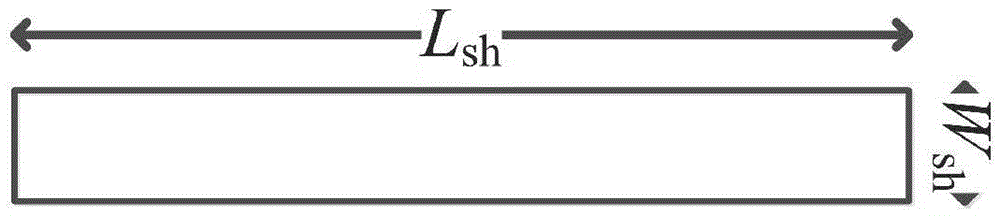

[0040] (1) Measure and estimate the structural dimensions such as the winding diameter, copper foil layer thickness, and winding spacing of the transformer.

[0041] The structural capacitance between the transformer winding and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com