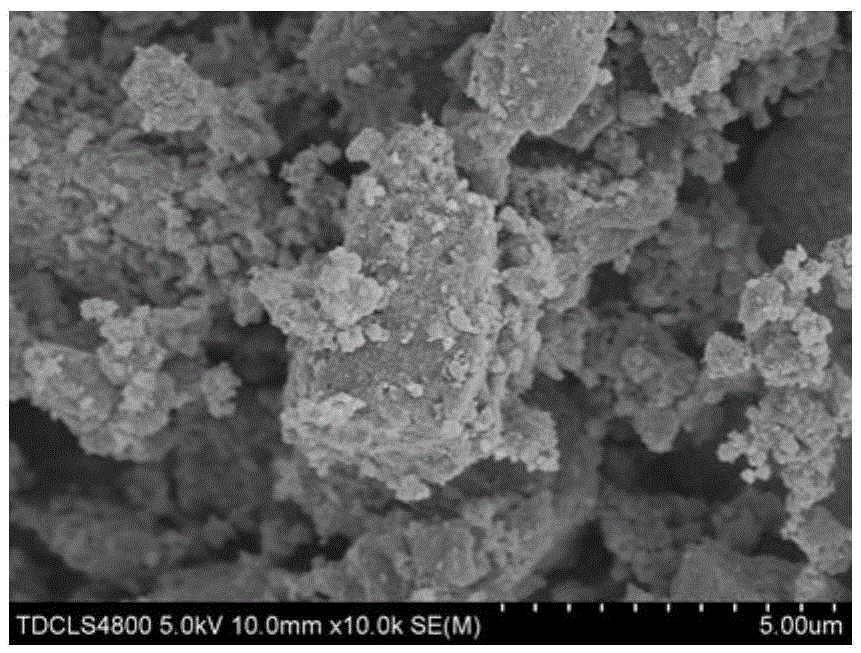

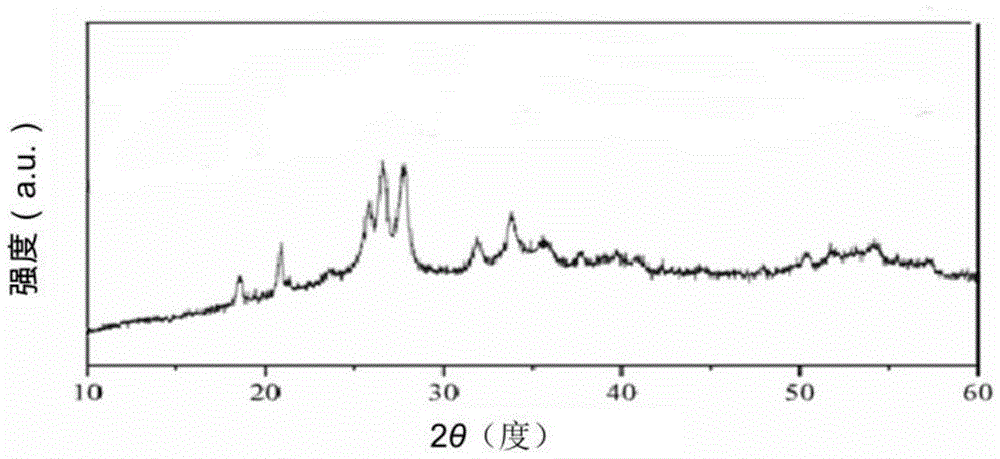

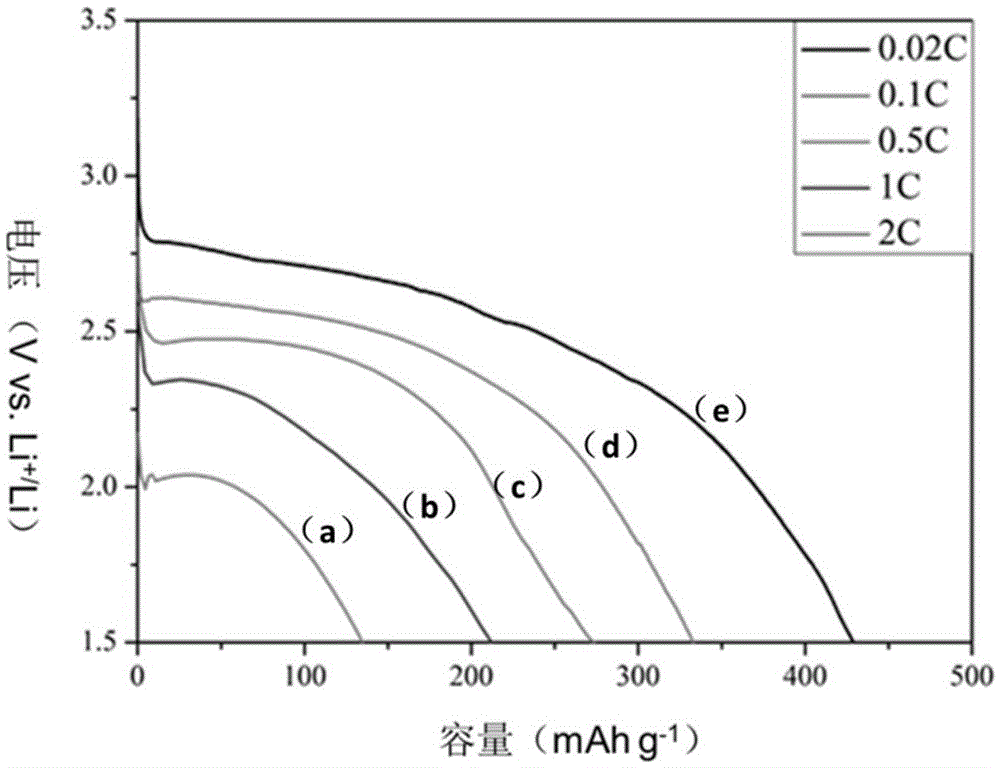

Preparation method for copper fluoride/molybdenum trioxide/graphene composite material and method for preparing electrode from copper fluoride/molybdenum trioxide/graphene composite material

A composite material, molybdenum trioxide technology, used in battery electrodes, circuits, electrical components, etc., can solve the problems of limited and low conductivity, and achieve the effects of simple operation, high output, good conductivity and electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] (1) Combining graphene with CuF 2 / MoO 3 The composite material was placed in an agate ball mill jar, and the mass of graphene accounted for CuF 2 / MoO 3 2% of the composite material mass, place 15 ball milling beads (12 small ball milling beads, 5nm in diameter; 3 large ball milling beads, 10nm in diameter), and cover the ball milling jar.

[0031] (2) Place the ball milling pot in (1) in a closed stainless steel mold stainless steel outer lining ball milling pot, and fill the mold with nitrogen.

[0032] (3) Place the mold in (2) on a planetary ball mill, and ball mill for 5 hours under the condition of 400rmp.

[0033] (4) Store the copper fluoride / molybdenum trioxide / graphene composite material powder obtained by ball milling in (3) in a vacuum oven at 80°C.

[0034] (5) Mix the composite material powder in (4) with acetylene black and polyvinylidene fluoride in a mass ratio of 8:1:1, and add 5ml of NMP dropwise to prepare the mixture into a uniform homogenate. ...

example 2

[0042] (1) Combining graphene with CuF 2 / MoO 3 The composite material was placed in an agate ball mill jar, and the mass of graphene accounted for CuF 2 / MoO 3 4% of the composite material mass, place 15 ball milling beads (12 small ball milling beads, 5nm in diameter; 3 large ball milling beads, 10nm in diameter), and cover the ball milling jar.

[0043] (2) Place the ball milling pot in (1) in a closed stainless steel outer lining ball milling pot, and fill the mold with nitrogen.

[0044](3) Place the mold in (2) on a planetary ball mill, and ball mill for 5 hours under the condition of 400rmp.

[0045] (4) Store the copper fluoride / molybdenum trioxide / graphene composite material powder obtained by ball milling in (3) in a vacuum oven at 80°C.

[0046] The above is the preparation of copper fluoride / molybdenum trioxide / graphene composite material.

[0047] (5) Mix the composite material powder in (4) with acetylene black and polyvinylidene fluoride in a mass ratio of ...

example 3

[0053] (1) Combining graphene with CuF 2 / MoO 3 The composite material was placed in an agate ball mill jar, and the mass of graphene accounted for CuF 2 / MoO 3 7% of the composite material mass, place 15 ball milling beads (12 small ball milling beads, 5nm in diameter; 3 large ball milling beads, 10nm in diameter), and cover the ball milling jar.

[0054] (2) Place the ball milling pot in (1) in a closed stainless steel outer lining ball milling pot, and fill the mold with nitrogen.

[0055] (3) Place the mold in (2) on a planetary ball mill, and ball mill for 5 hours under the condition of 400rmp.

[0056] (4) Store the copper fluoride / molybdenum trioxide / graphene composite material powder obtained by ball milling in (3) in a vacuum oven at 80°C.

[0057] The above is the preparation of copper fluoride / molybdenum trioxide / graphene composite material.

[0058] (5) Mix the composite material powder in (4) with acetylene black and polyvinylidene fluoride in a mass ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com