A kind of low molecular soybean peptide and preparation method thereof

A soybean peptide and low-molecular technology, applied in the field of low-molecular soybean peptide and its preparation, can solve the problems of non-concentrated molecular weight of soybean peptide products, difficult to control product quality, difficult to absorb, etc., and achieve remarkable absorption effect, small molecular weight, and concentrated molecular weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

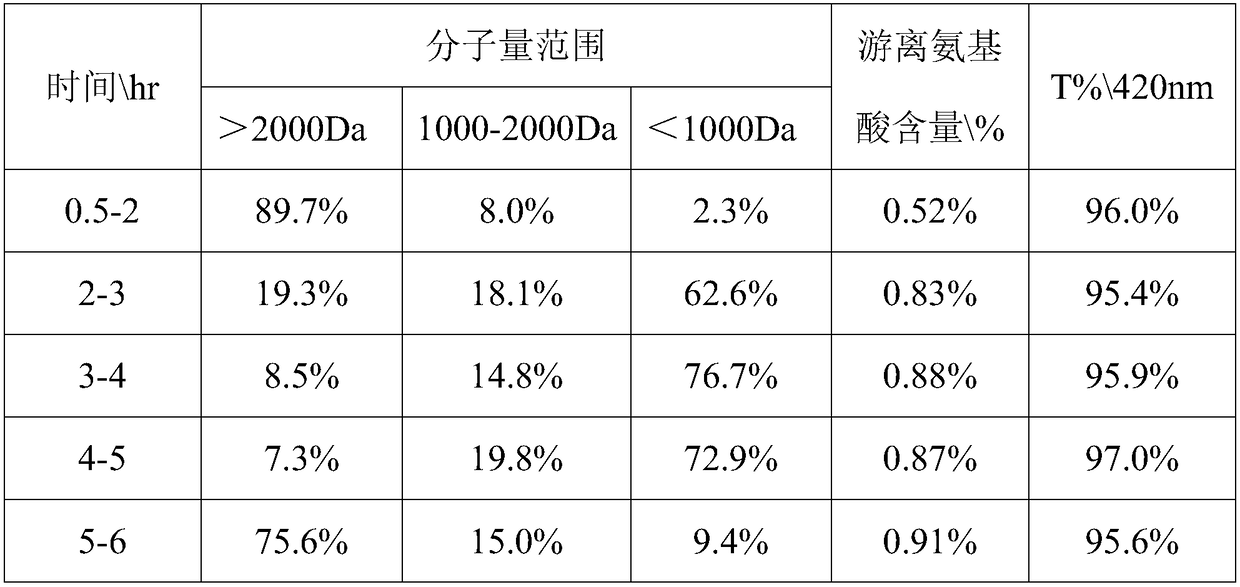

Examples

Embodiment 1

[0034] The low-molecular-weight soybean peptide of this embodiment is prepared by the following method, and the specific operation steps are:

[0035] 1) Dissolve soybean protein isolate in RO pure water at 30°C, and add NaOH solution with a mass concentration of 25% to adjust the pH value to 7 to obtain solution 1; the mass ratio of soybean protein isolate to RO pure water is 1:12;

[0036]2) Add complex protease to the solution 1 prepared in step 1) at 55°C, and stir for 4 hours for enzymolysis to obtain solution 2; , add composite protease 1 to solution 1, wherein the mass ratio of composite protease 1 to soybean protein isolate is 0.5:100, after enzymolysis for 2 hours; add composite protease 2 obtained by compounding ficin and Aspergillus niger, wherein composite protease The mass ratio of 2 to soybean protein isolate is 0.5:100. After 1 hour of enzymolysis, add 537 acid protease, the mass ratio of 537 acid protease to soybean protein isolate is 0.2:100, and the enzymoly...

Embodiment 2

[0041] The low-molecular-weight soybean peptide of this embodiment is prepared by the following method, and the specific operation steps are:

[0042] 1) Under the condition of 20°C, dissolving soybean protein isolate in RO pure water, and adding NaOH solution with a mass concentration of 10% to adjust the pH value to 5, so that the soybean protein isolate was dissolved to obtain solution 1; wherein the soybean protein isolate was mixed with The mass ratio of RO pure water is 1:10;

[0043] 2) Add compound protease step by step to solution 1 prepared in step 1) at 40°C, stir and enzymatically hydrolyze for 3 hours to obtain solution 2; first, take papain and pineapple Protease and 3942 neutral protease are compounded to obtain composite protease 1, and composite protease 1 is added in solution 1, wherein the mass ratio of composite protease 1 to soybean protein isolate is 1:100, after enzymolysis for 1 hour; The compound protease 2 obtained by compounding Aspergillus, wherein...

Embodiment 3

[0048] The low-molecular-weight soybean peptide of this embodiment is prepared by the following method, and the specific operation steps are:

[0049] 1) Under the condition of 45°C, dissolving soybean protein isolate in RO pure water, and adding NaOH solution with a mass concentration of 40% to adjust the pH value to 9, so that the soybean protein isolate was dissolved to obtain solution 1; wherein the soybean protein isolate was mixed with The mass ratio of RO pure water is 1:15;

[0050] 2) Add the compound protease step by step to the solution 1 prepared in step 1) at 70°C, stir for 5 hours for enzymolysis to obtain solution 2; wherein the compound protease is obtained by compounding papain, bromelain, and 3942 neutral protease Protease 1, compound protease 1 is added in solution 1, wherein the mass ratio of compound protease 1 and soybean protein isolate is 1:100, after enzymolysis 2 hours; Add the compound protease 2 that is obtained by compounding ficin and Aspergillus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com