Preparation method of Fe (III)-containing magnetic nano material

A magnetic nanometer and magnetic particle technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as high energy consumption, high reaction temperature, and complex reaction conditions, and achieve low energy consumption , environmental friendliness and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

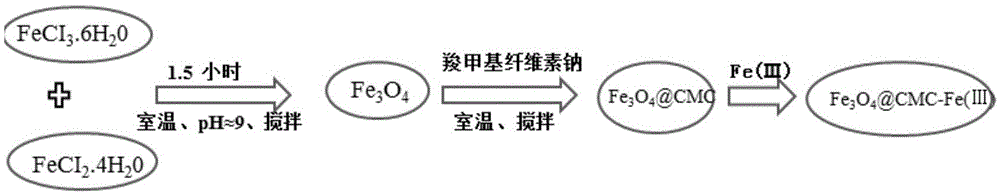

[0013] Specific embodiment 1: This embodiment is a preparation method of Fe(Ⅲ)-containing magnetic nanomaterial, which is specifically completed by the following steps:

[0014] 1. Preparation of magnetic particles: ①, FeCI 3 ·6H 2 O was dissolved in deionized water I, and sonicated under nitrogen for 20min~40min to obtain FeCI with a concentration of 0.270g / mL 3 Solution, ②, FeCI 2 ·4H 2 O was dissolved in deionized water Ⅱ, and sonicated under nitrogen protection for 20min~40min to obtain FeCI with a concentration of 0.099g / mL 2 Solution, ③, the FeCI concentration of 0.270g / mL 3 Solution and FeCI with a concentration of 0.099g / mL 2 The solution is mixed, and the mixed solution is obtained after mixing. Adjust the pH of the mixed solution to 8.5~9.5 with 2mol / L ammonia solution, then stir for 1h~1.5h at the temperature of 25~30℃, and separate the solid and liquid to obtain the black solid product. , First rinse the black solid product with deionized water 2 to 3 times, then rinse ...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and the specific embodiment one is: in step one ①, FeCI 3 ·6H 2 O was dissolved in deionized water I, and sonicated for 30 minutes under nitrogen protection to obtain FeCI with a concentration of 0.270g / mL 3 Solution. Others are the same as the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: This embodiment is different from specific embodiment one or two in that: in step one ②, FeCI 2 ·4H 2 O was dissolved in deionized water Ⅱ, and sonicated under nitrogen protection for 20min~40min to obtain FeCI with a concentration of 0.099g / mL 2 Solution. Others are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com