Roller coating method used in polyolefin thermoplastic elastomer products

A technology of thermoplastic elastomers and polyolefins, which is applied to devices and coatings for coating liquid on the surface, can solve problems such as easy scrapping, increased processes, and high requirements for storage conditions, so as to save material resources, simplify production processes, and reduce The effect of manual input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

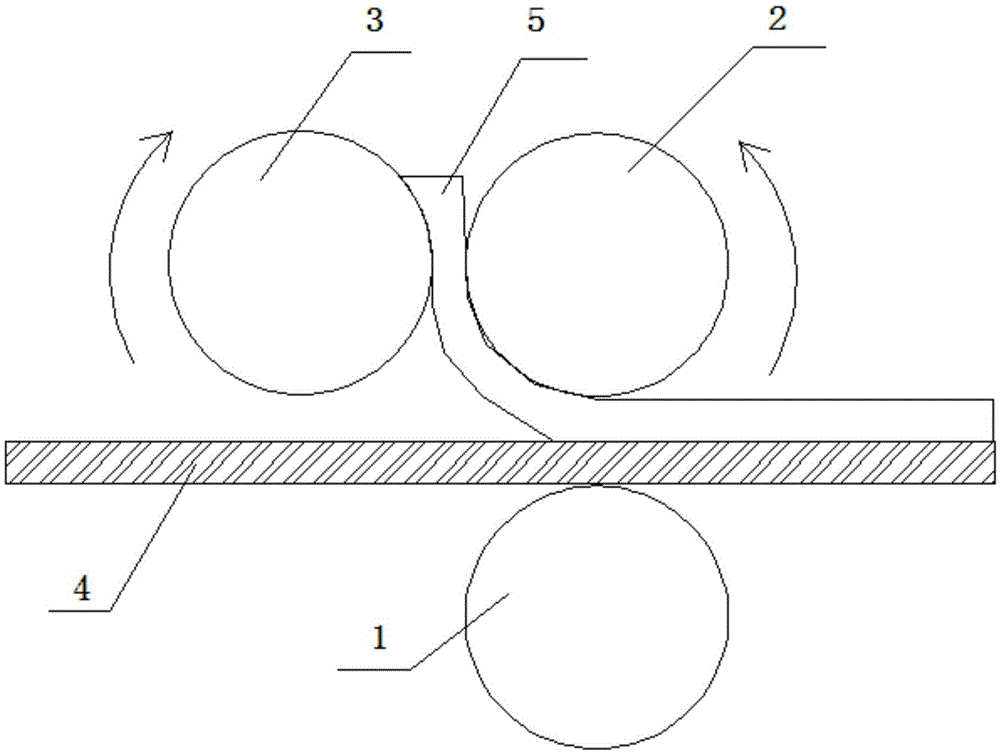

[0027] Such as figure 1 As shown, the present embodiment discloses a roller coating device, which is used for rolling hot melt adhesive on polyolefin thermoplastic elastomer products, and the roller coating device at least includes: a transmission steel roller driven by a driving device 1, set The first steel roll 2 below the above-mentioned transmission steel roll, the second steel roll 3 arranged on the side of the above-mentioned first steel roll 2, the above-mentioned transmission steel roll 1 and the first steel roll 2 are tangent up and down, and the above-mentioned first steel roll The steel roller 2 and the second steel roller 3 are tangent left and right, and the PP foam TPO material 4 passes between the above-mentioned driving steel roller 1 and the first steel roller 2. Between roll 1 and a second steel roll 3 flows for coating.

[0028] The above-mentioned roller coating device is applied in the process of roller coating hot melt adhesive on polyolefin thermoplast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com