Preparation method of white carbon black-doped high performance concrete

A high-performance concrete and silica technology, applied in the field of engineering building materials, can solve the problems of difficult processing and high price of mineral ultrafine powder, and achieve the effects of excellent self-compacting workability, low cost and improving compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] A method for preparing high-performance concrete mixed with white carbon black. When preparing high-performance concrete mixed with white carbon black, 16-20 parts of Portland cement, 0.1-0.5 parts of micro-silica fume, and 28-35 parts of mountain sand are taken in parts by weight. 33-41 parts of crushed stone, 5-7 parts of water, 0.3-0.6 parts of admixture, 1-2 parts of white carbon black, and the high-performance white carbon black mixed with each raw material can be obtained after the improved concrete production process concrete.

[0012] Wherein the improved concrete production process is as follows: mix the Portland cement, microsilica fume, mountain sand, gravel and white carbon black in the parts by weight, pour the mixed raw materials into a mixer, and stir for 20 ~30s, then add the water and the admixture of the said weight part again, after stirring for 100~120 seconds, the finished concrete product is obtained, and the molecular formula of the white carbon b...

specific Embodiment 1

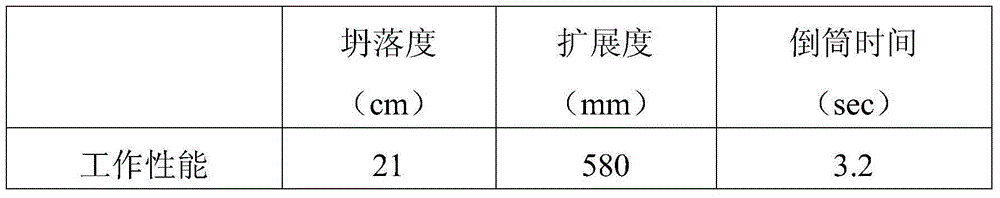

[0013] Using 16 parts of Portland cement, 1 part of white carbon black, 33.5 parts of mountain sand, 42 parts of gravel, 7 parts of water, and 0.5 part of admixture to make concrete products, the performance test of the mixture was carried out, and the results are shown in Table 1. Show:

[0014] Table 1

[0015]

[0016] Results: The working performance of the test product is excellent, which can meet the technical requirements of pumping construction on the construction site.

[0017] Then the concrete of Test Example 1 was made into two groups of 150×150×150mm specimens, demoulded after 24h, placed in the curing room for 7d and 28d, and then the compressive strength test was carried out. The results are shown in Table 2:

[0018] Table 2

[0019]

Embodiment 2

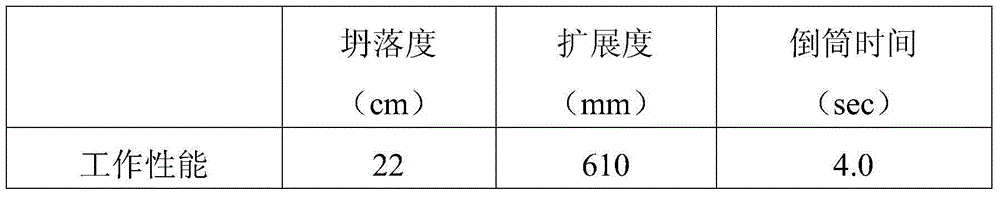

[0021] Using 17 parts of Portland cement, 1.2 parts of white carbon black, 0.1 part of microsilica, 35 parts of mountain sand, 40 parts of gravel, 6.2 parts of water and 0.5 parts of admixtures to make concrete products, the performance test of the mixture was carried out. The results are shown in Table 3:

[0022] table 3

[0023]

[0024] Results: The working performance of the test product is excellent, which can meet the technical requirements of pumping construction on the construction site.

[0025] Then the concrete of Test Example 2 was made into two groups of 150×150×150mm specimens, demoulded after 24h, placed in the curing room for 7d and 28d, and then the compressive strength test was carried out. The results are shown in Table 4:

[0026] Table 4

[0027]

7 days 28 days

[0028] Concrete compressive strength (MPa) 67.5 80.5

[0029] The above test shows that the 60-80MPa concrete produced by the present invention has excel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com