Environmentally friendly low-viscosity high-strength polyurethane grouting lifting material and preparation method thereof

An environmentally friendly, grouting lifting technology, applied in the field of lightweight grouting lifting materials and their preparation, can solve the problems of accelerated physical foaming agent escape, foam structure damage, repair point collapse, etc., to achieve low cost and high cost. Compression strength, easy storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

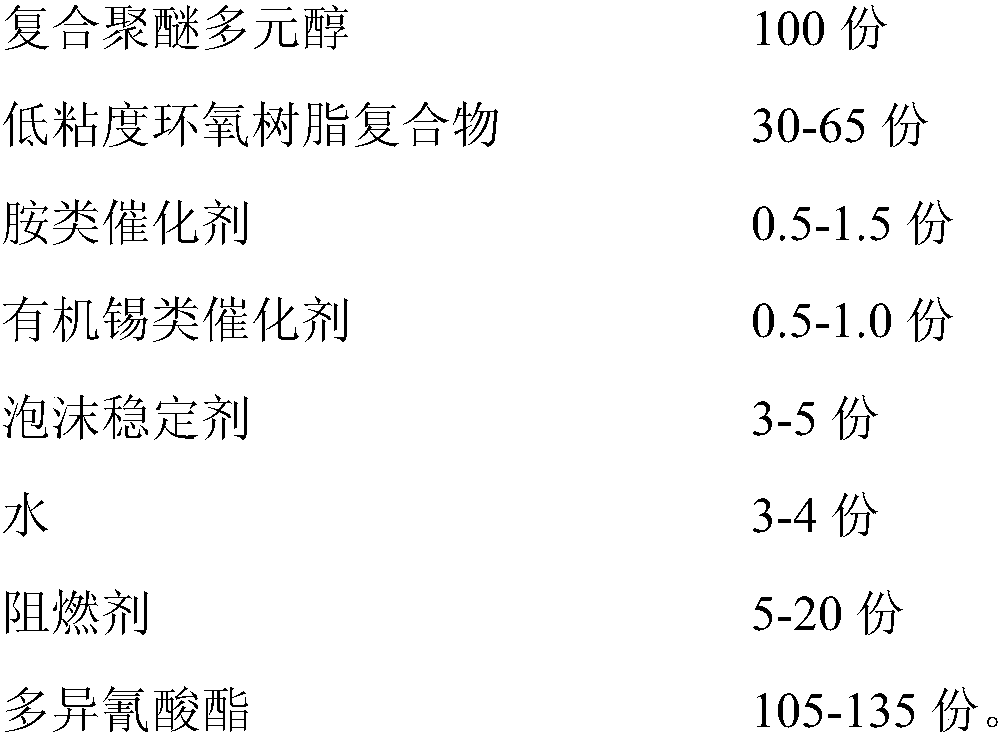

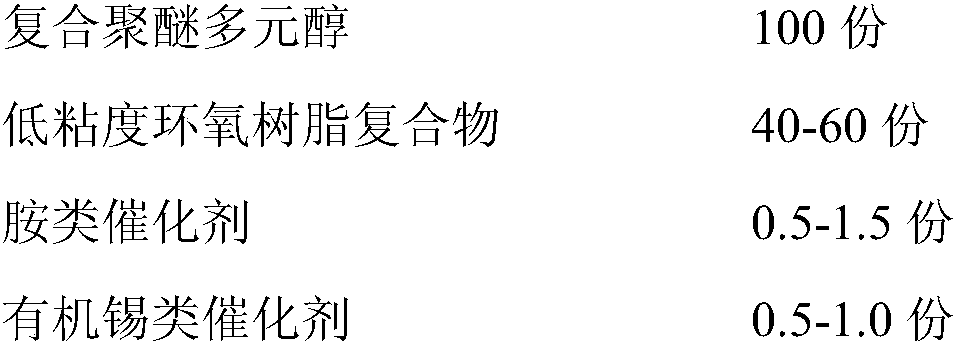

Method used

Image

Examples

Embodiment 1

[0041] 1. At room temperature, weigh 90 parts of polyether polyol 460 (functionality 3.2, number average molecular weight 550, viscosity 250-450mPa·s), 10 parts of polyether polyol 4110 (functionality 4, number average molecular weight 500, Viscosity 2500-4500mPa·s) is placed in a dried reactor to obtain a composite polyether polyol.

[0042] 2. Add 40 parts of low-viscosity epoxy resin compound (30 parts of epoxy resin E-44 and 10 parts of reactive diluent neopentyl glycol diglycidyl ether) into the dried reaction kettle and compound polyether polyol Mix well, then add 1.0 parts of 2,4,6-tris(dimethylaminomethyl)phenol, 4 parts of foam stabilizer AK-8805, 3 parts of deionized water and 10 parts of dimethyl methylphosphonate in sequence, and stir Disperse evenly to obtain component A.

[0043] 3. Weigh 110 parts of polyisocyanate PAPI and 0.5 part of T12, stir and disperse evenly to obtain component B.

[0044] 4. Mix component A and component B at a volume ratio of 1:1, foa...

Embodiment 2

[0049] 1. At room temperature, weigh 90 parts of polyether polyol 460 (functionality 3.2, number average molecular weight 550, viscosity 250-450mPa·s), 10 parts of polyether polyol 4110 (functionality 4, number average molecular weight 500, Viscosity 2500-4500mPa·s) is placed in a dried reactor to obtain a composite polyether polyol.

[0050]2. Add 40 parts of low-viscosity epoxy resin compound (30 parts of epoxy resin E-51 and 10 parts of reactive diluent neopentyl glycol diglycidyl ether) into the dried reaction kettle and compound polyether polyol Mix well, then add 1.0 parts of 2,4,6-tris(dimethylaminomethyl)phenol, 4 parts of foam stabilizer AK-8805, 3 parts of deionized water and 10 parts of dimethyl methylphosphonate in sequence, and stir Disperse evenly to obtain component A.

[0051] 3. Weigh 110 parts of polyisocyanate PAPI and 0.5 part of T12, stir and disperse evenly to obtain component B.

[0052] 4. Mix component A and component B at a volume ratio of 1:1, foam...

Embodiment 3

[0057] 1. At room temperature, weigh 70 parts of polyether polyol 460 (functionality 3.2, number average molecular weight 550, viscosity 250-450mPa·s), 30 parts of polyether polyol 4110 (functionality 4, number average molecular weight 500, Viscosity 2500-4500mPa·s) is placed in a dried reactor to obtain a composite polyether polyol.

[0058] 2. Add 50 parts of low-viscosity epoxy resin compound (35 parts of epoxy resin E-44 and 15 parts of reactive diluent neopentyl glycol diglycidyl ether) into the dried reaction kettle and compound polyether polyol Mix well, then add 1.5 parts of 2,4,6-tris(dimethylaminomethyl)phenol, 4 parts of foam stabilizer AK-8805, 3 parts of deionized water and 10 parts of dimethyl methylphosphonate in sequence, and stir Disperse evenly to obtain component A.

[0059] 3. Weigh 115 parts of polyisocyanate PAPI and 0.5 part of T12, stir and disperse evenly to obtain component B.

[0060] 4. Mix component A and component B at a volume ratio of 1:1, foa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com