Nanometer-material-compounded long-glass-fiber-reinforced polypropylene material and preparing method thereof

A technology of polypropylene materials and nanomaterials, which is applied in the field of nanocomposite long glass fiber reinforced polypropylene composite materials and its preparation, can solve the problem of increasing the proportion of long glass fiber reinforced polypropylene, unfavorable long glass fiber reinforced polypropylene processing, and affecting the production of polypropylene. Problems such as propylene melt flow characteristics, to achieve the effect of improving tensile strength, good market prospects and economic benefits, and low warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

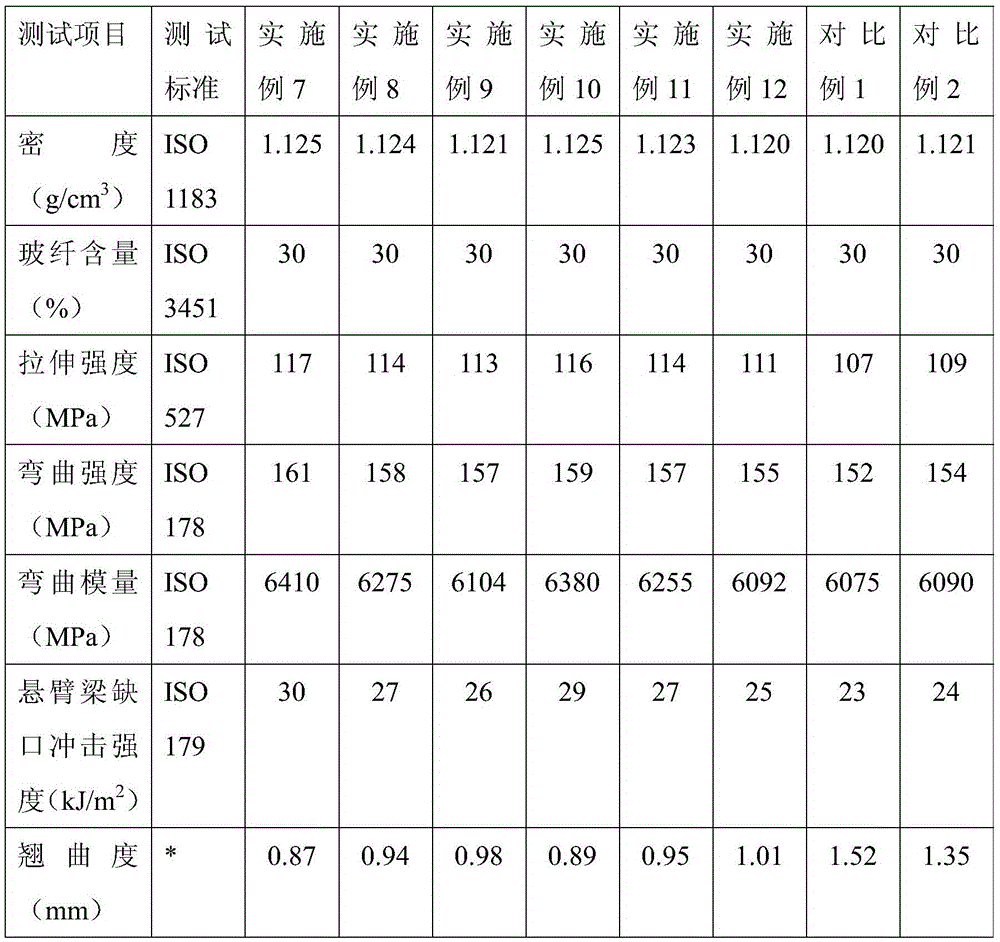

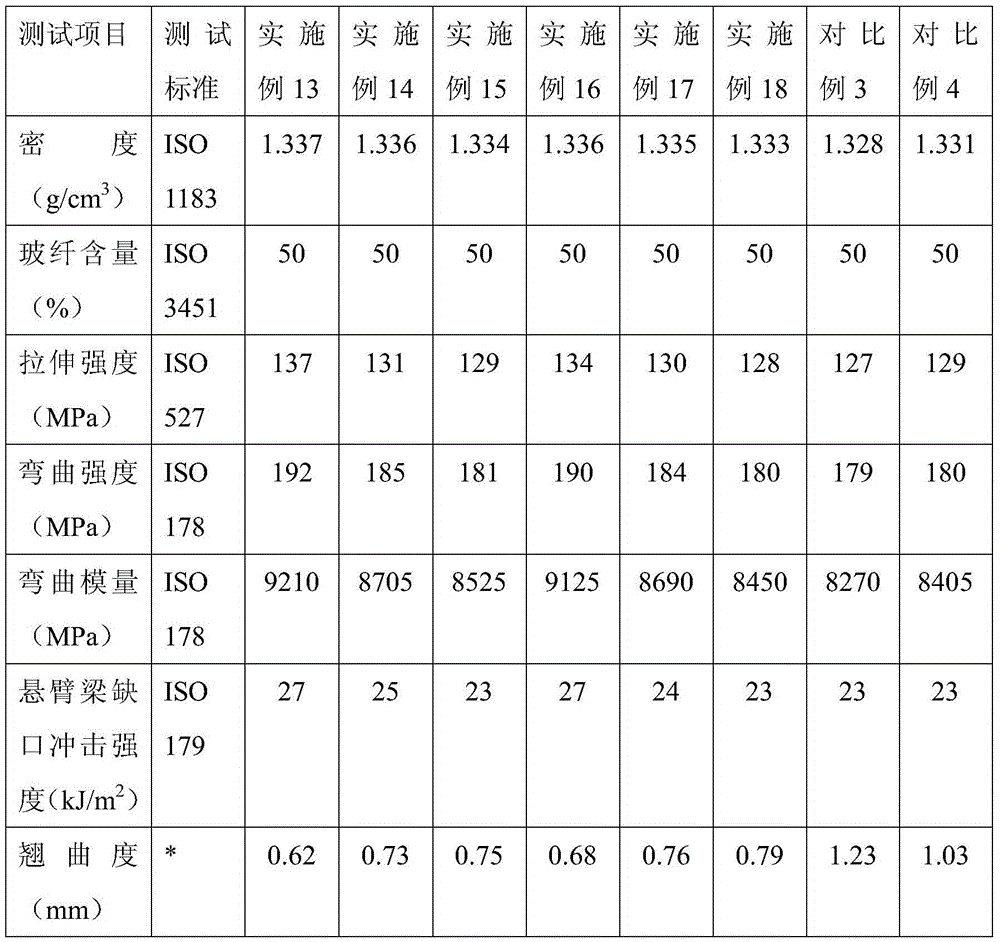

Examples

Embodiment 1

[0032] In the present embodiment, the nanomaterial masterbatch is prepared as follows:

[0033] First, add 6.9kg of Honeywell polyethylene wax AC-629A and 0.1kg of sorbitan monooleate into a 20L reactor, set the heating temperature to 150°C, and turn on the agitator after the polyethylene wax melts. Stirring speed 500rpm, slowly add 3kgWackerN20 fumed silica (12nm) into the reaction kettle, after the addition is complete, stir and mix for 1 hour, take out the molten mixture, cool and solidify, and obtain nanomaterial masterbatch particles after crushing, the average particle size 3mm.

Embodiment 2

[0035] In the present embodiment, the nanomaterial masterbatch is prepared as follows:

[0036]First, add 6.9kg of modified ethylene bis fatty acid amide TAF and 0.1kg of sorbitan monopalmitate into a 20L reaction kettle, set the heating temperature to 150°C, and turn on the stirrer after the TAF is melted, and the stirring speed is 500rpm , slowly add 3kg AEROXIDE gas-phase nano-alumina AluC (13nm) into the reaction kettle, after the addition is complete, stir and mix for 1 hour, take out the molten mixture, cool and solidify, and obtain nano-alumina masterbatch particles after crushing, with an average particle size of 3mm .

Embodiment 3

[0038] In the present embodiment, described nanomaterial masterbatch is prepared as follows:

[0039] First, add 6.9kg of pentaerythritol tetrastearate and 0.1kg of sorbitan trioleate into a 20L reactor, set the heating temperature to 120°C, and after the pentaerythritol tetrastearate melts, start the agitator, Stirring speed 500rpm, 3kgDegussa gas-phase method nano-titanium dioxide AEROXIDETiO 2 P25 (21nm) was slowly added to the reactor, after the addition was completed, stirred and mixed for 1 hour, the molten mixture was taken out, cooled and solidified, and pulverized to obtain nanometer titanium dioxide masterbatch particles with an average particle size of 3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com