Anti-high temperature bridging plugging agent suitable for lost circulation in deep and ultra-deep formations

A technology of anti-high temperature and plugging agent, which is applied in the field of plugging agent, can solve the problems of low pressure bearing capacity of plugging layer, easy re-leakage, poor suspension stability, etc., and achieve good plugging density, high plugging success rate, The effect of strong pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

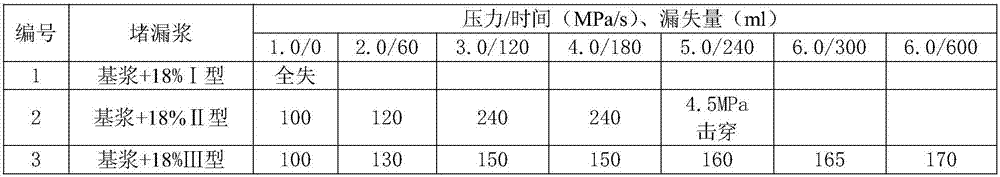

Method used

Image

Examples

Embodiment 1

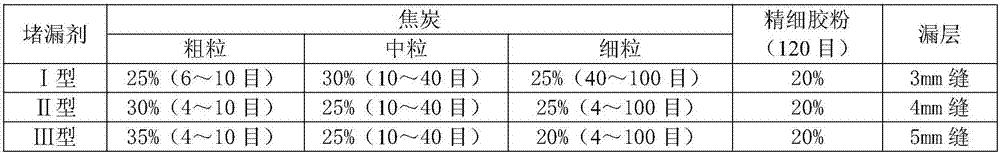

[0027] Example 1 Leakage plugging test with 3mm slit plate

[0028] Use type I plugging agent, prepare plugging slurry according to the above steps, install a 3mm slit plate on the QD-2 type plugging material test device, and conduct a plugging test to test the plugging effect of type I plugging agent on 3mm simulated cracks .

[0029]

[0030] It can be seen from the above table that after the instantaneous leakage of 120ml, the plugging layer is formed, and the total leakage amount in 10 minutes is only 165ml. The plugging layer has good compactness and can withstand a pressure of at least 6MPa.

Embodiment 2

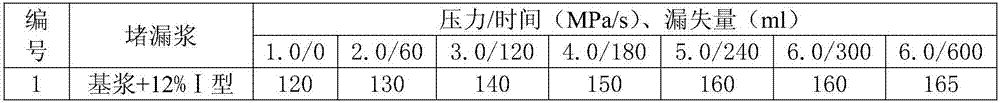

[0031] Example 2 Plugging experiment of matching plugging agent type and slit plate

[0032] Different types of plugging agents and 5mm slit plates were used to conduct plugging experiments to evaluate the effect of plugging agent type (bridging particle size) on the plugging effect.

[0033]

[0034] The data in the above table shows that the particle size of bridging particles has a direct impact on the plugging effect. When the particle size is too low, the plugging agent cannot bridge in the cracks, cannot form a plugging layer, and the plugging slurry is completely lost. If the particle size of the bridging particles is reasonable but the concentration is low, even if the plugging layer is formed, the pressure bearing capacity is not enough, and the plugging layer is broken down under the action of 4.5MPa pressure, and the plugging fails. Only when the particle size of the bridging particles matches the fracture, the size of the particles is properly gradated, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com