Combination type tunnel lining, culvert or underground comprehensive pipe gallery

A comprehensive pipe gallery and combined technology, applied in the field of steel pipes, can solve the problems that the support strength cannot be strictly guaranteed, affect the progress of the project, and invest in large equipment, so as to reduce the area of the excavation section, save the amount of engineering, and increase the bearing capacity. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

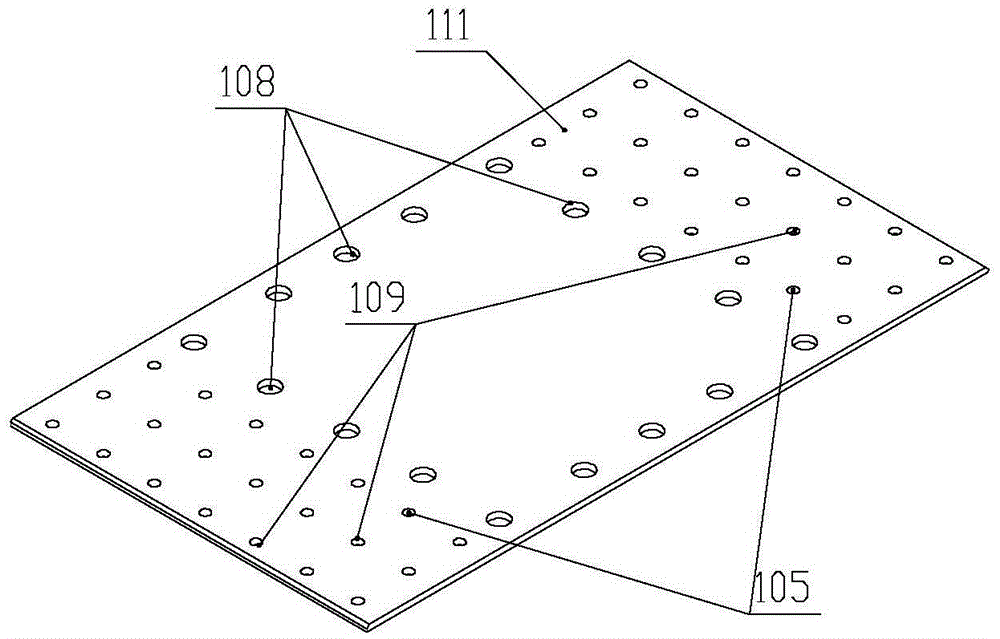

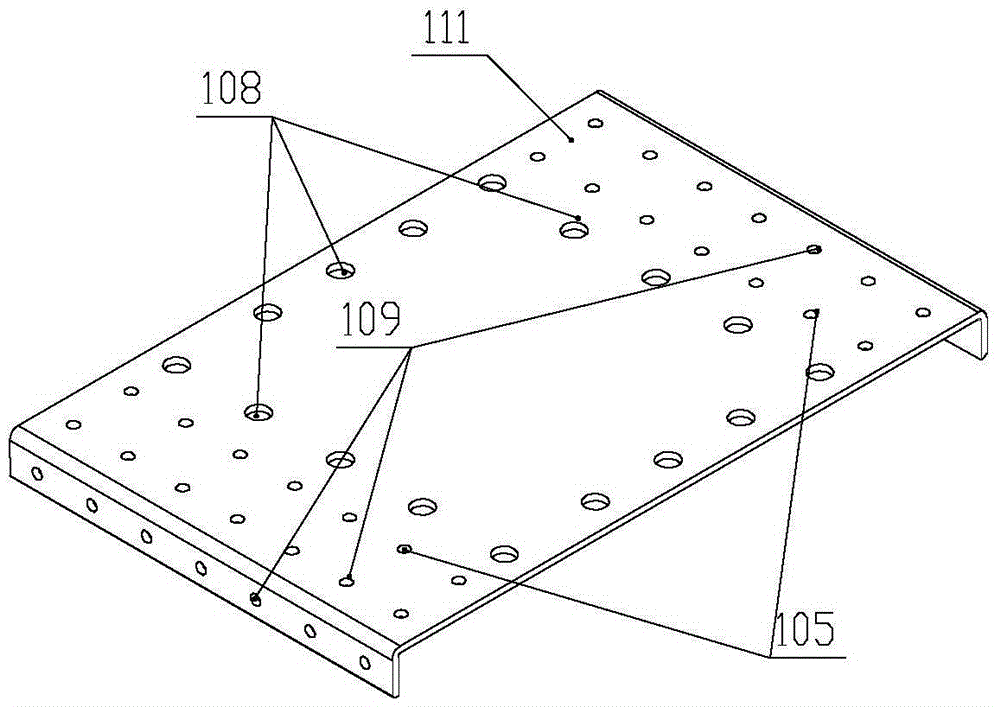

[0027] The invention discloses a combined tunnel lining, culvert or underground comprehensive pipe gallery, which includes a pipeline 100 assembled from curved unit plates 101 along the circumferential and axial directions; wherein, when the unit plates 101 are spliced along the axial direction, The contact end of adjacent unit plates 101 has a hollow cavity structure 104, the cross-sectional periphery of the hollow cavity structure 104 is closed, and the contact surface of the adjacent hollow cavity structure 104 is a splicing connection surface, such as Figure 9 , 10 , 11, 12 shown. Preferably, a connection hole 105 may be opened on the contact surface, and connected by workpieces such as bolts. Since the hollow cavity structure is located outside the tunnel, culvert or underground comprehensive pipe gallery, a splicing operation hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com