A metallurgical gas-fired boiler combustion optimization control system

A combustion optimization and control system technology, applied in the direction of combustion method, combustion control, fuel supply adjustment, etc., can solve the problems of large false liquid level, load influence, large deviation of desuperheating water measurement, etc., and achieve self-seeking of air-fuel ratio Excellent, increase smoke loss, stable combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

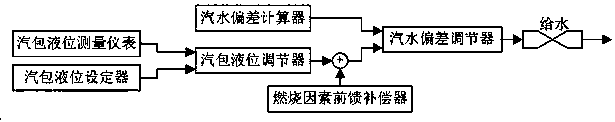

[0041] Drum Level Control Circuit

[0042] The steam drum liquid level regulator adopts the PID control algorithm. The set value of the steam drum liquid level is L_SP, the measured value of the steam drum liquid level is L_PV, and the output is L_AV. The value range of the parameter P in the PID control algorithm is 200~250 , the value range of parameter I is 200 to 300, and the value range of parameter D is 30 to 40; the basic soda deviation QS_JB output by the soda deviation calculator is the current soda deviation value recorded at the moment of automatic adjustment of the drum level control loop, namely

[0043] IF GSAUTO=TRUE THEN

[0044] QS_JB=QS_AV

[0045] Among them, GSAUTO is the enabling signal of the automatic adjustment of the drum liquid level, and QS_AV is the output value of the drum liquid level regulator;

[0046] The set value of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com