Modeling method for pulverized coal fired boiler combustion optimization

A modeling method and combustion optimization technology, which is applied in the field of pulverized coal boiler control and combustion process optimization control of pulverized coal boiler, can solve the problems of many variable influences, reduce model complexity, and long modeling time, etc., and achieve a reliable model foundation , Reduce modeling time and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A kind of modeling method of pulverized coal boiler combustion optimization of the present invention, concrete steps comprise:

[0017] Step 1, using the 3σ criterion to eliminate the data with gross errors collected from the distributed control system (DCS);

[0018] Step 2, using the intelligent evolutionary genetic algorithm to reduce the dimensionality of the model independent variables of the boiler combustion process;

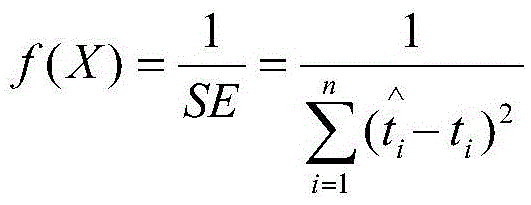

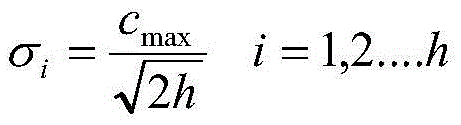

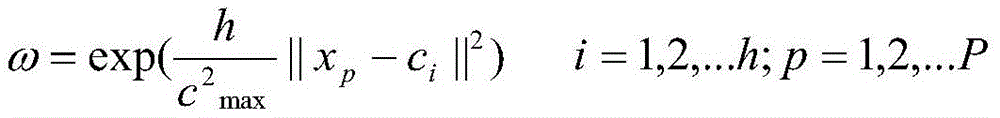

[0019] Step 3. On the basis of the model independent variable screening, use the radial neural network to establish X A soft-sensing model targeting emissions and fly ash carbon content;

[0020] Step 4: Analyze the fitting error and prediction error of the established model, and correct the model parameters.

[0021] Among them, in the process of genetic algorithm optimization calculation, the design steps are:

[0022] 1. Generation of initial population. Randomly generate N initial string data structures, each string structure is an individu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com