RFLDMOS device and manufacturing method thereof

A manufacturing method and device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of snapback effect, device voltage failure, poor robustness, etc., achieve large breakdown voltage, avoid The effect of failure of pressure resistance and improvement of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

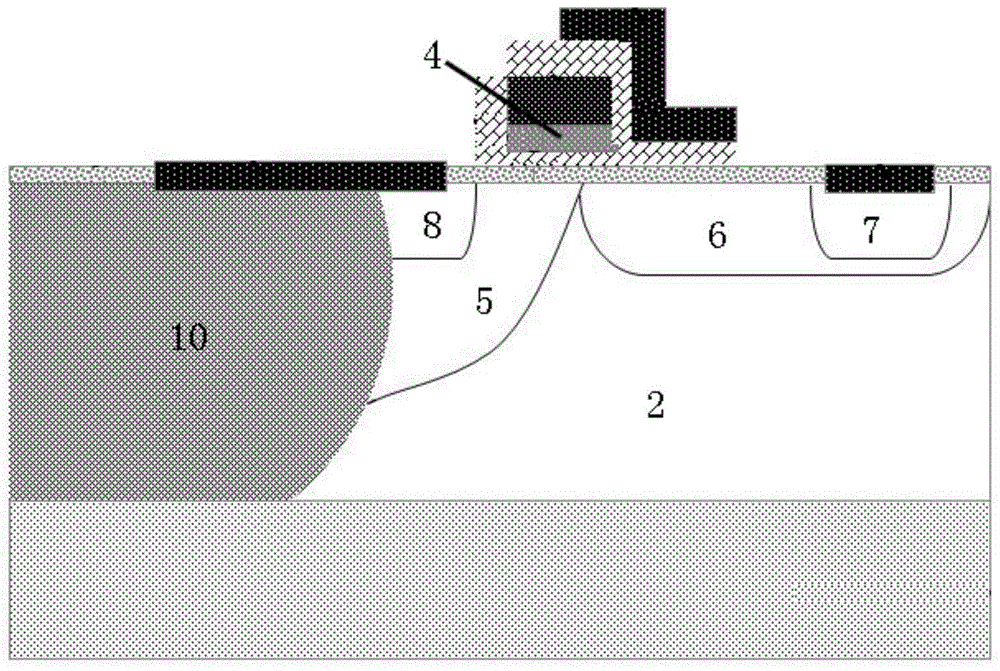

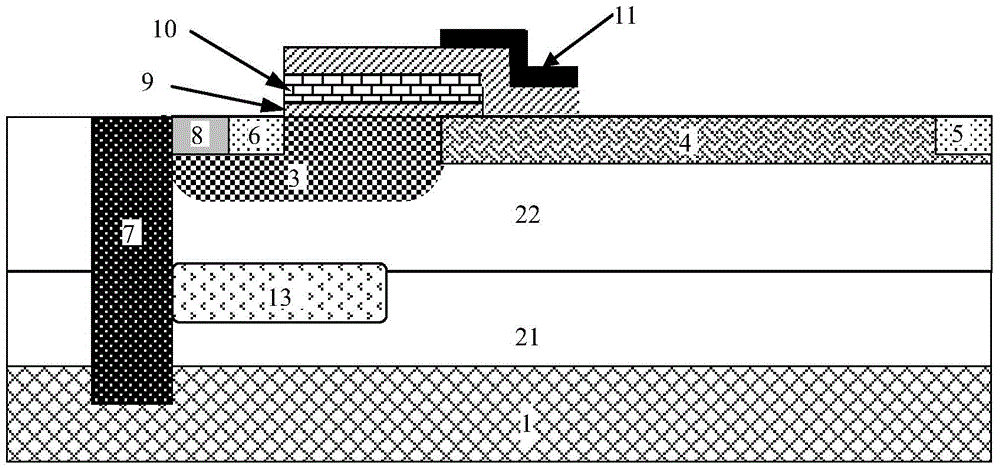

[0064] RFLDMOS (Radio Frequency Laterally Diffused Metal Oxide Semiconductor) devices such as image 3 as shown,

[0065] A first layer of P epitaxy 21 is formed on the P substrate 1;

[0066] A second layer P epitaxy 22 is formed on the first layer P epitaxy 21;

[0067] In the second layer P epitaxy 22, a P well 3 is formed in the left part, and a drain N-type lightly doped region 4 is formed in the right part;

[0068] The drain N-type lightly doped region 4 has a drain N-type heavily doped region 5 formed on the right;

[0069] The P well 3 is connected to a contact column 7 on the left side, and a source terminal N-type heavily doped region 6 is formed in the middle;

[0070] The contact column 7 is connected to the second layer P epitaxy 22, the first layer P epitaxy 21 and the P substrate 1;

[0071] A bulk P-type heavily doped region 8 communicating with the contact pillar 7 is formed on the upper part of the P well 3 on the left side of the N-type heavily doped re...

Embodiment 2

[0090] A method for manufacturing an RFLDMOS (radio frequency laterally diffused metal oxide semiconductor) device, comprising the following steps:

[0091] One. grow the first layer of P epitaxy 21 on the P substrate 1, as Figure 4 shown;

[0092] 2. Photolithography, carry out P-type ion implantation in the first layer P epitaxy 21, form P buried layer (PBuriedLayer), as Figure 5 shown;

[0093] 3. Remove photoresist 15, form second layer P epitaxy 22 on first layer P epitaxy 21, as Figure 6 shown;

[0094] The P-type doping concentration of the first layer P epitaxy 21 is greater than the P-type doping concentration of the second layer P epitaxy 22;

[0095] 4. Forming P well 3, drain N-type lightly doped region 4, source N-type heavily doped region 6, bulk P-type heavily doped region 8, drain N-type heavily doped region 5, gate oxide 9, Polysilicon gate 10, Faraday shield (Faradayshield) 11, metal contact post 7, such as image 3 shown;

[0096] P well 3 is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com