Liquid catalyzing system

一种液体、液体循环的技术,应用在醋的制备、食品制备、酒精饮料的制备等方向,能够解决干扰酒液风味、增加肝脏代谢负担、饮用者宿醉等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

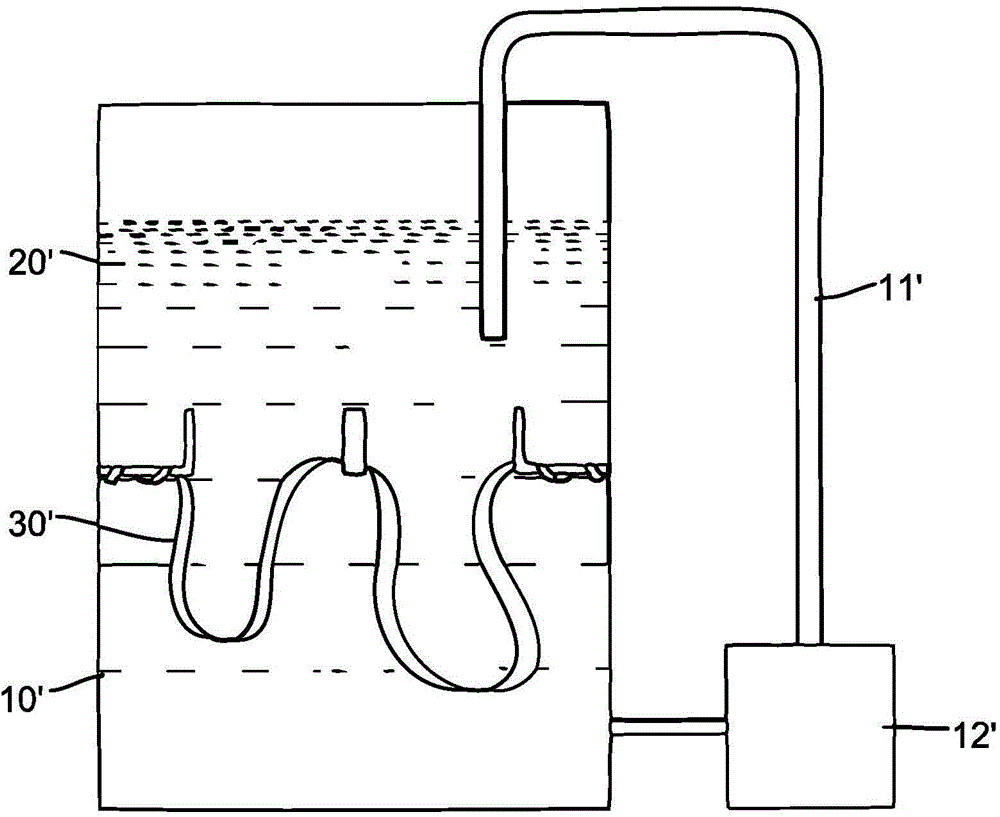

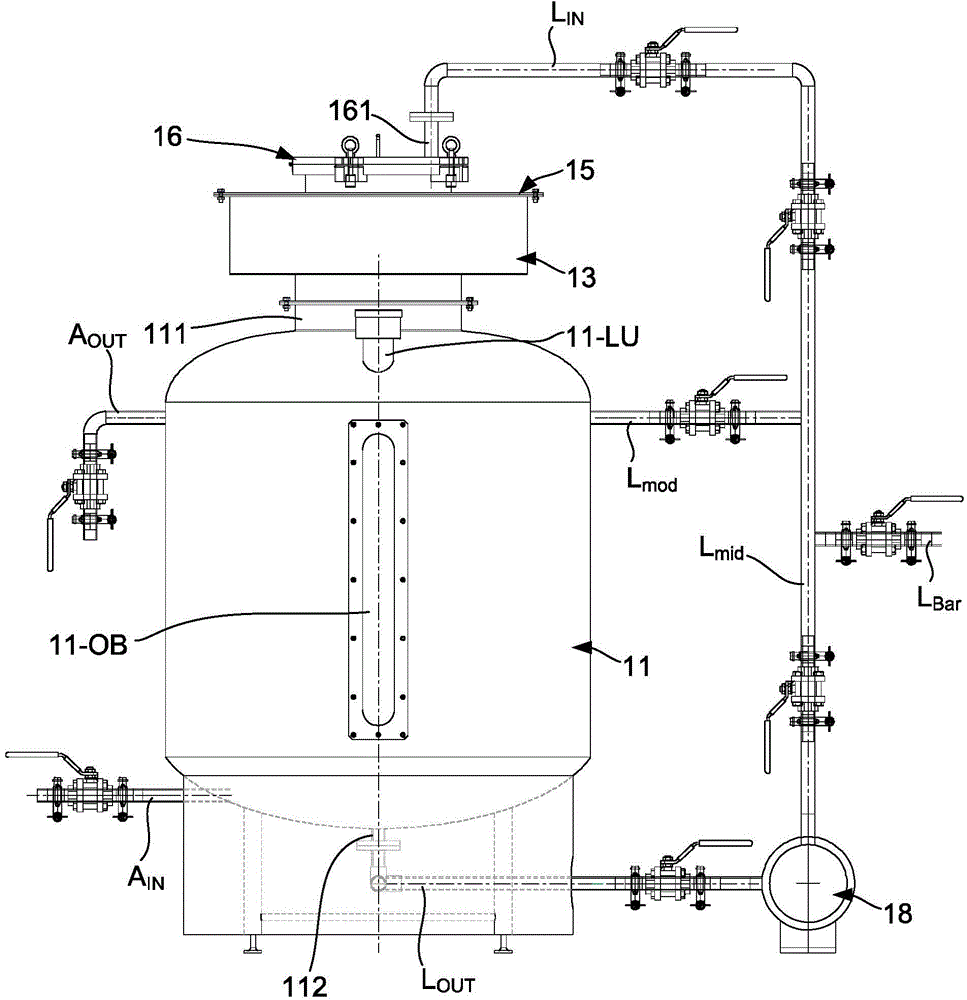

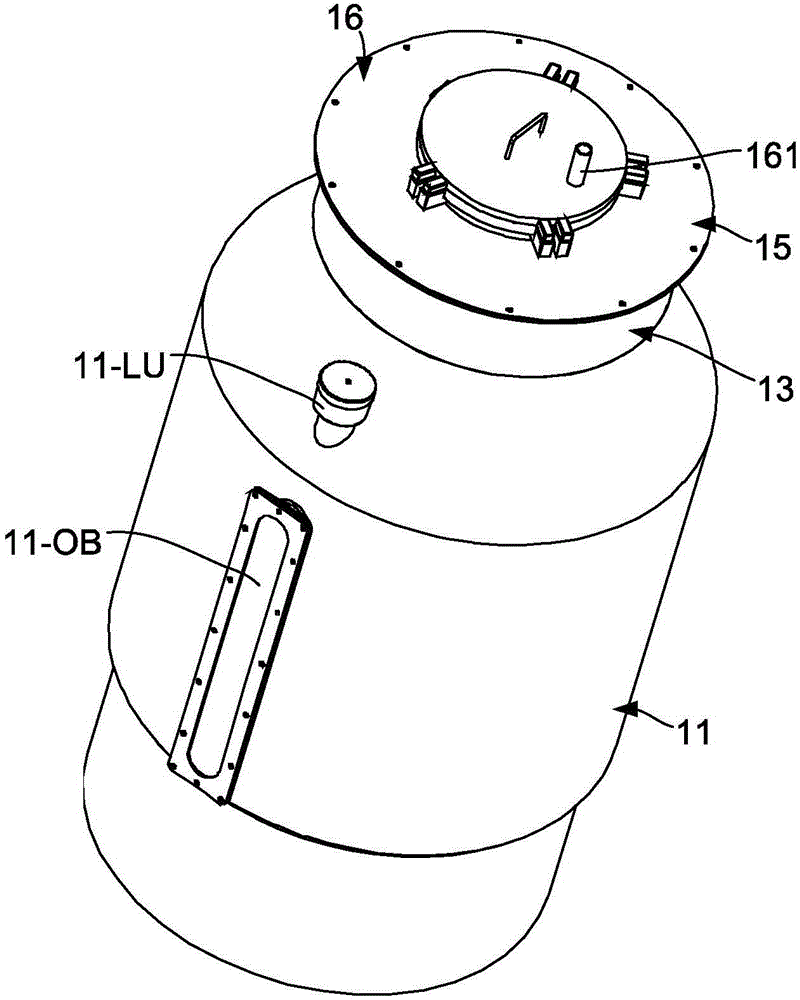

[0077] In order to describe a liquid ripening system proposed by the present invention more clearly, preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0078] Please also see Figure 2 to Figure 6 ,in, figure 2 It is a structural diagram of a liquid ripening system of the present invention, image 3 is a perspective view of a liquid aging barrel of the liquid ripening system, Figure 4 It is a three-dimensional view of a liquid aging barrel, a first buffer tank, a liquid injection part, a cover, and a flip-type cover of the liquid ripening system, Figure 5 is another perspective view of the first buffer tank and the liquid injection part, and Figure 6 It is a three-dimensional view of a bracket, a filter screen and the liquid injection part of the liquid ripening system.

[0079] Such as Figure 2 to Figure 6 As shown, the components of the liquid ripening system include: a liquid ripening bar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com