Forming method for hollow thin-wall uniform-thickness titanium alloy sealing ring

A forming method and titanium alloy technology, which is applied in the forming field of hollow thin-walled titanium alloy sealing ring with uniform thickness, can solve the problems of prone to fatigue fracture, poor wall thickness uniformity, fatigue fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

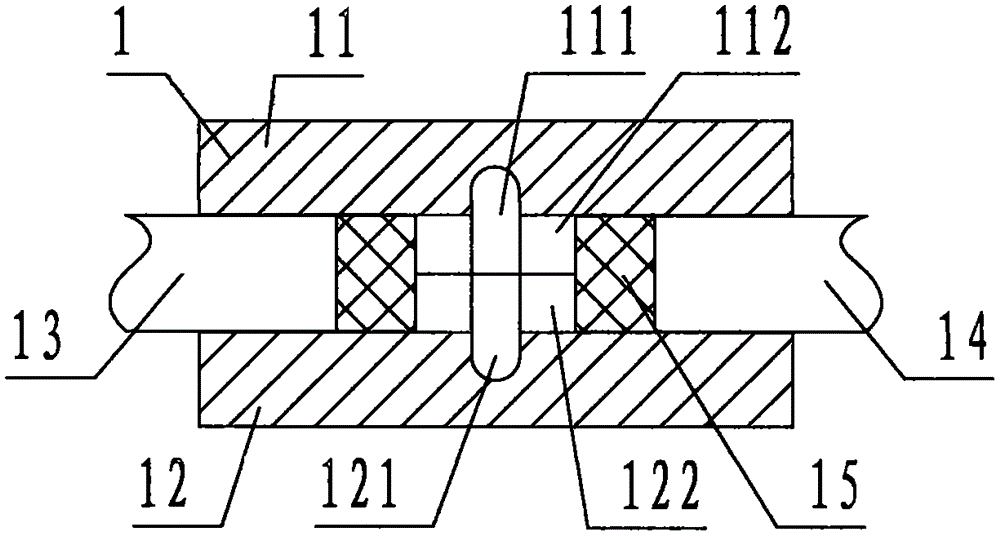

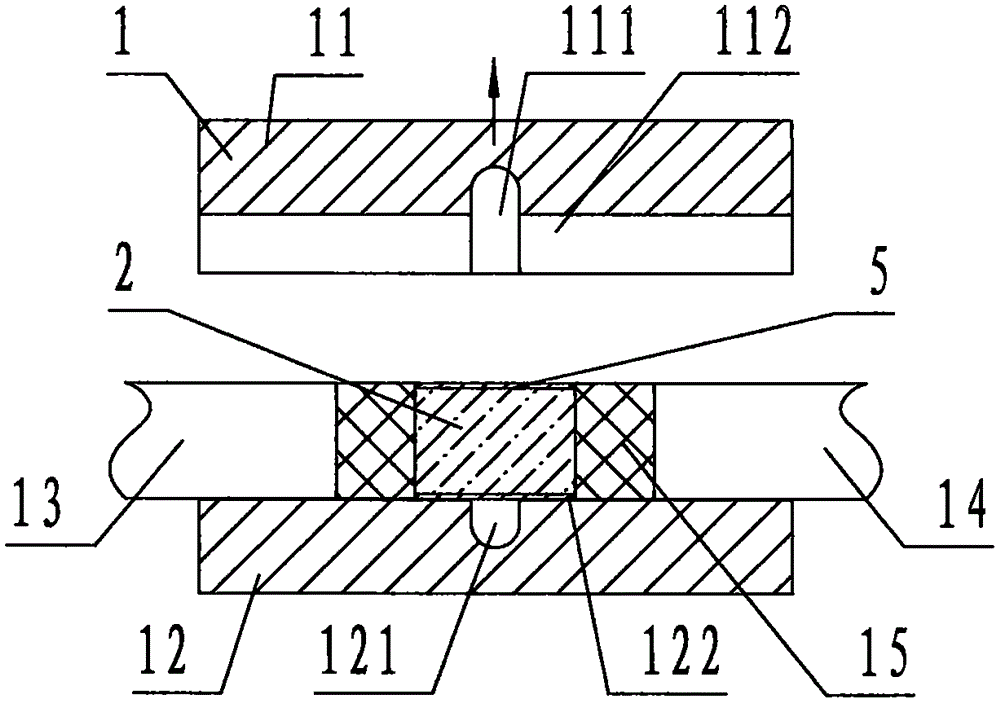

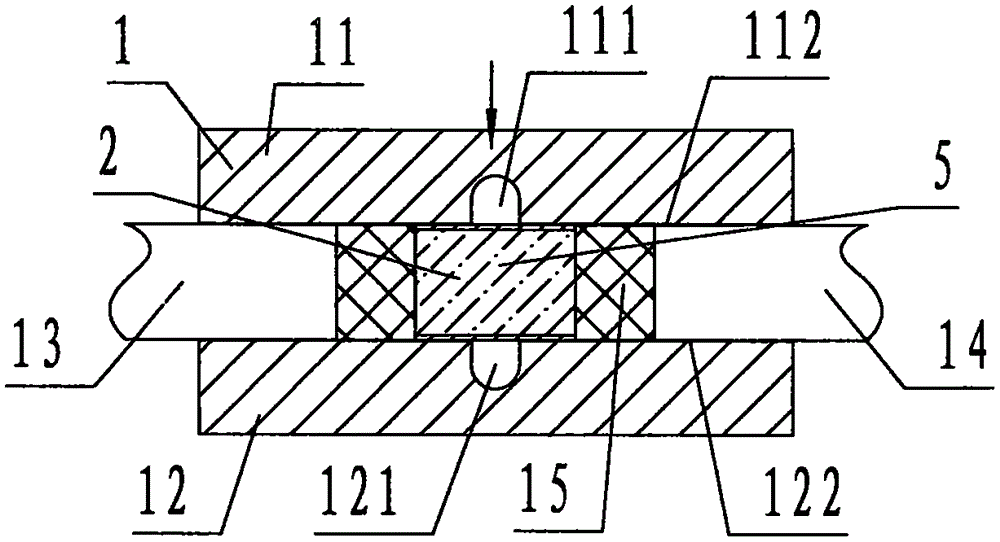

[0031] refer to Figure 1 to Figure 8 , a method for forming a hollow thin-walled uniform-thickness titanium alloy sealing ring of the present invention includes a mold 1 and a process method, wherein: the mold 1 includes an upper mold 11, a lower mold 12, a left punch 13 and a right punch 14, Described upper die 11 is the steel component that is provided with upper die cavity 111 below, and described upper die cavity 111 is the semi-cavity model of the upper half shape surface of molding product 4, and the left and right sides of upper die cavity 111 are provided with Left and right directions, the semicircular through groove is called upper slideway 112;

[0032] Described lower die 12 is the steel component that is provided with lower die cavity 121 above, and described lower die cavity 121 is the semi-cavity model of molded product 4 lower half, and the left and right sides of lower die cavity 121 are provided with left and right directions. 1. The semicircular through gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com