Electrostatic dust suppression device of belt conveyor and control method thereof

A belt conveyor, electrostatic technology, applied in the direction of transportation and packaging, electrostatic cleaning, conveyors, etc., can solve the problems of unsatisfactory purification effect, difficulty in achieving energy saving, and poor dust purification effect, so as to save labor costs and run The effect of low power and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

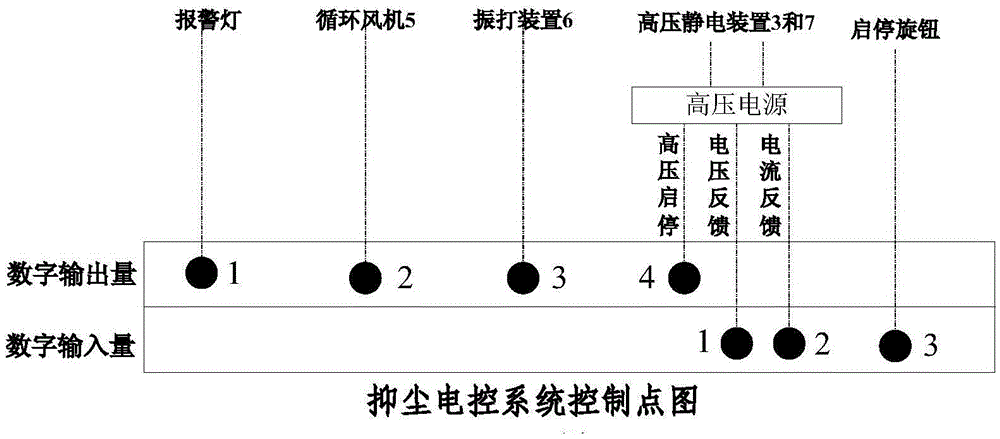

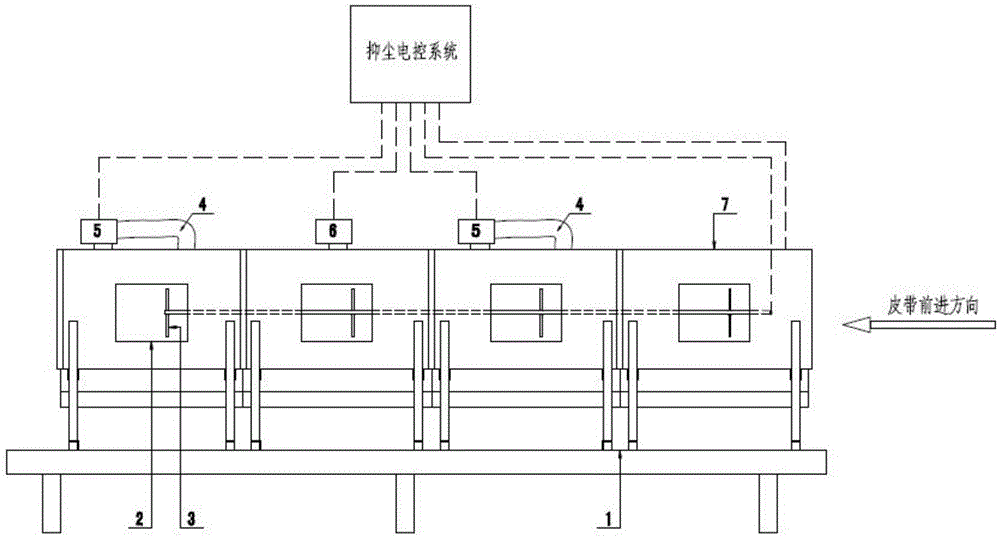

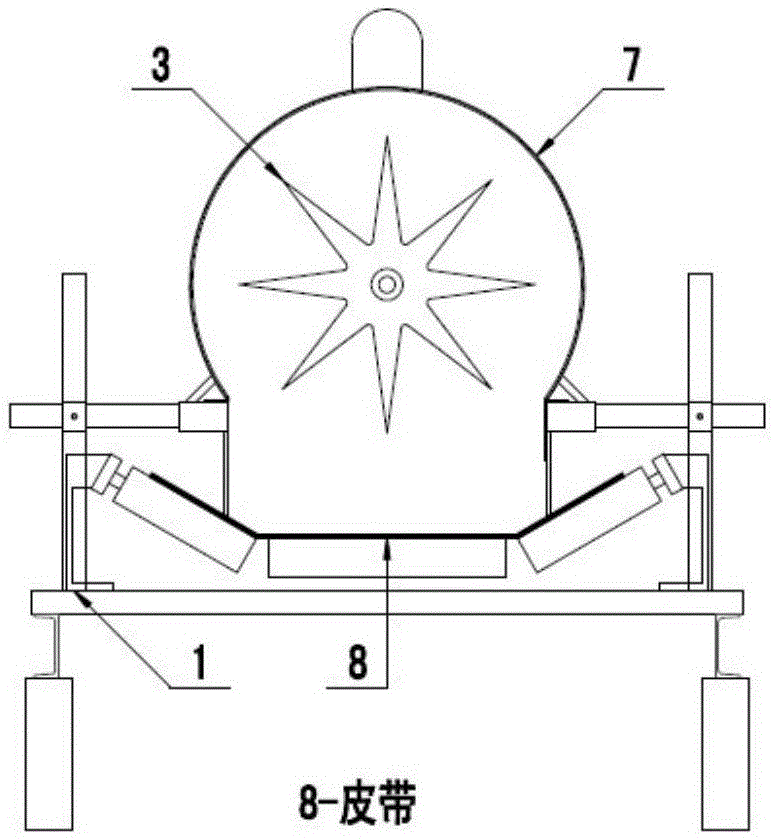

[0018] see figure 1 with figure 2 , The main body of the dust suppression device of the present invention is mainly composed of a circulating fan 5, a rapping device 6, a high-voltage electrostatic device 3 and 7 (3 is a cathode, and 7 is an anode). A closed cavity covering the belt 8 is formed between the metal cylinder 7 and the belt conveyor frame 1 .

[0019] The function of the circulation fan 5 is to disturb the dust-laden airflow surrounded by the main body cylinder 7 of the dust suppression device, so as to better promote the electrostatic adsorption effect;

[0020] The effect of the rapping device 6 is that when the electrostatic device cylinder wall 7 and the cathode electrode 3 (comprising the connection line between a plurality of cathode electrodes 3) are more dusty and adsorbed and cannot come off naturally, the rapping device will be used to remove the accumulated dust. Dust shakes off from cathode 3 and anode 7;

[0021] The function of high-voltage electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com