Manufacturing method of decorative porcelain

A production method and technology of colored porcelain, applied to clay products, other household utensils, household utensils, etc., can solve the problems of increasing the difficulty and workload of the production process, difficulty in uniform chroma on the surface of porcelain, time-consuming and labor-intensive operation, etc., to achieve The manufacturing process is simple, the production process is reduced, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Make porcelain with black and white stripes

[0077] (1) Prepare white porcelain clay and black porcelain clay

[0078] Choose white clay as the raw material porcelain clay.

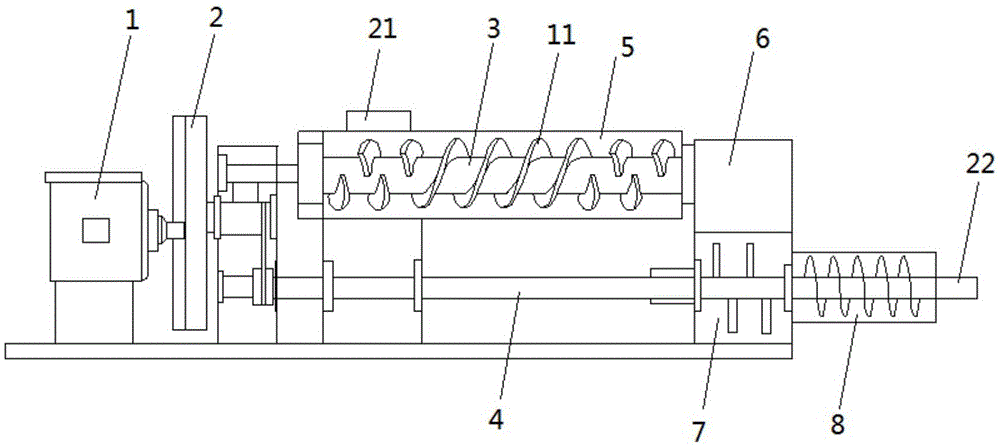

[0079] (a) putting the selected white clay into the first vacuum mud refiner to refine the mud to obtain white porcelain clay;

[0080] (b) Add raw material white clay to a mixer, then add a certain proportion of black coloring material, and stir evenly; put the evenly stirred porcelain clay into a second vacuum mud refiner to refine the clay to obtain black porcelain clay.

[0081] Among them, when making white porcelain clay and black porcelain clay, the proportion of water should be consistent.

[0082] The mud outlet of the mud refining machine used is rectangular, and the size of the mud outlet is 15cmx3mm, that is, the porcelain clay extruded through the mud outlet is 15cm wide and 3mm thick.

[0083] Use a cutting machine to cut the porcelain clay coming out of the vacuum mud refining ma...

Embodiment 2

[0092] Make porcelain with red and blue stripes

[0093] Among them, white clay is selected as the raw material porcelain clay.

[0094] (a) Add raw material white clay into a mixer, then add a certain proportion of red coloring material, and stir evenly; put the evenly stirred porcelain clay into the first vacuum mud refiner to refine the clay to obtain red porcelain clay.

[0095] (b) Add raw material white clay to a mixer, then add a certain proportion of blue coloring material, and stir evenly; put the evenly stirred porcelain clay into a second vacuum mud refiner to refine the clay to obtain blue porcelain clay.

[0096] Except for preparing the red porcelain clay and the blue porcelain clay respectively and sequentially laminating the red porcelain clay and the blue porcelain clay to a predetermined height, the colorful porcelain was prepared according to the same method as in Example 1.

Embodiment 3

[0098] Make porcelain with red, yellow and blue stripes

[0099] Among them, white clay is selected as the raw material porcelain clay.

[0100] (a) Add raw material white clay into a mixer, then add a certain proportion of red coloring material, and stir evenly; put the evenly stirred porcelain clay into the first vacuum mud refiner to refine the clay to obtain red porcelain clay.

[0101] (b) Add raw material white clay into a mixer, then add a certain proportion of yellow coloring material, and stir evenly; put the evenly stirred porcelain clay into a second vacuum mud refiner to refine the clay to obtain yellow porcelain clay.

[0102] (c) adding raw material white clay into a mixer, then adding a certain proportion of blue coloring material, and stirring evenly; putting the evenly stirred porcelain clay into a third vacuum mud refiner to refine the clay to obtain blue porcelain clay.

[0103] Except for preparing red porcelain clay, yellow porcelain clay and blue porcela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com