Preparation method of diethyl n-butylmalonate

A technology of diethyl n-butylmalonate and diethyl malonate, which is applied in the field of preparation of diethyl n-butylmalonate, can solve the problem of increasing the production cost of diethyl n-butylmalonate and other problems, to achieve the effect of reducing production cost, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A preparation method for n-butyl malonate, comprising the following steps:

[0017] 1) ethanol and sodium react to generate sodium ethylate;

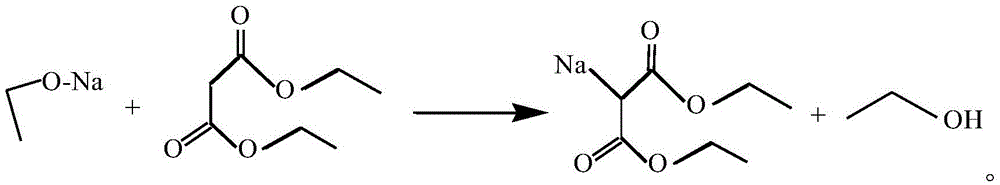

[0018] 2) adding diethyl malonate to the sodium ethylate obtained in step 1), generating diethyl malonate sodium salt;

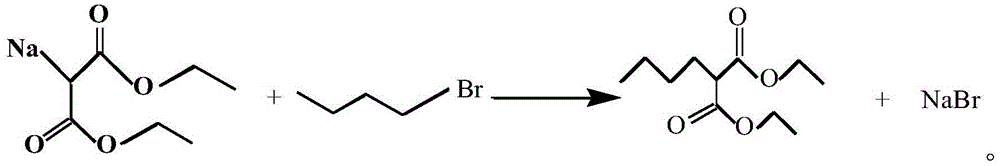

[0019] 3) Add bromobutane to the diethyl malonate sodium salt obtained in step 2), and react to generate n-butyl diethyl malonate.

[0020] The present invention uses ethanol, sodium, diethyl malonate and bromobutane as raw materials without catalyst, reduces the cost of n-butyl diethyl malonate, and the yield of n-butyl diethyl malonate High, high purity, in line with drug quality standards.

[0021] Wherein, the reaction of ethanol and sodium generates the reaction formula of sodium ethylate as follows:

[0022] Na+C 2 h 5 OH→C 2 h 5 ONa+H 2 ↑.

[0023] In the embodiment of the present invention, the preparation of sodium ethylate is in N 2 Prepared under atmosphere, avoiding the problem of easy dec...

Embodiment 1

[0035] Feed N into the reaction kettle filled with 900g ethanol 2 , add 90g of sodium to absolute ethanol, and after reacting for 12h at 73°C, stop feeding N 2 ; At the same time, heat the temperature to 80°C to remove ethanol to obtain sodium ethylate; then pass cooling water into the cooling water jacket of the reactor for 30 minutes, and then pass into N 2 , and slowly add 600g diethyl malonate dropwise to sodium ethylate, stop feeding cooling water and N 2 , to obtain diethyl malonate sodium salt; 590g of bromobutane was added dropwise, and kept at 76°C for 30 minutes, filtered and rectified to obtain diethyl n-butylmalonate.

[0036] The yield of diethyl n-butylmalonate prepared in this example was 76.42%, and the purity was 99.57%.

Embodiment 2

[0038] Feed N into the reactor containing 1200g ethanol 2 , add 96g of sodium to absolute ethanol, at 73°C, after 14h of reaction, stop feeding N 2 At the same time, heat the temperature to 80°C to remove ethanol to obtain sodium ethylate; then pass cooling water into the cooling water jacket of the reactor for 60 minutes, and then pass into N 2 , and slowly add 600g diethyl malonate dropwise to sodium ethylate, stop feeding cooling water and N 2 , to obtain diethyl malonate sodium salt; 600g of bromobutane was added dropwise, and kept at 80°C for 45min, filtered and rectified to obtain diethyl n-butyl malonate.

[0039] The yield of diethyl n-butylmalonate prepared in this example was 76.48%, and the purity was 99.69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com