Supported type semi-cage type aquo-complex phase change heat storage material and preparing method and application thereof

A phase change heat storage, semi-cage technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem of no phase change temperature and phase change latent heat, short life cycle of heat storage medium, and unstable dynamic performance and other problems, to achieve the effect of small phase change volume change, long life cycle, and stable room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of a supported semi-clathrate hydrate phase-change heat storage material (a load-type semi-clathrate hydrate phase-change heat storage material with a mass fraction of tetraisopentylammonium bromide of 30%) is as follows: 3 g tetraisoammonium bromide Add pentyl ammonium bromide to 6.97g of water at a temperature of 60°C, stir to dissolve, then add 0.03g of expanded graphite, and stir at 60°C and 700r / min for 120 minutes to obtain a supported semi-clathrate hydrate Phase change thermal storage materials.

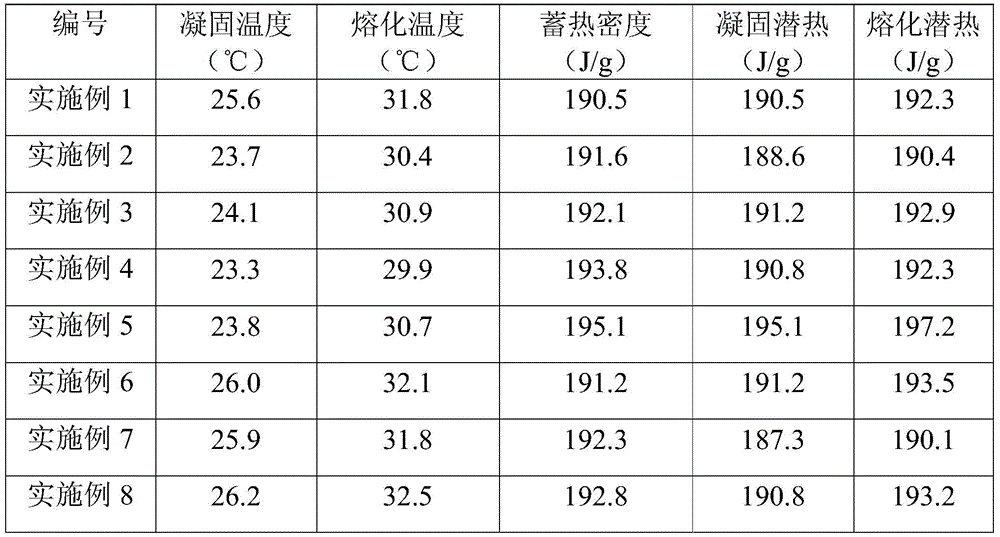

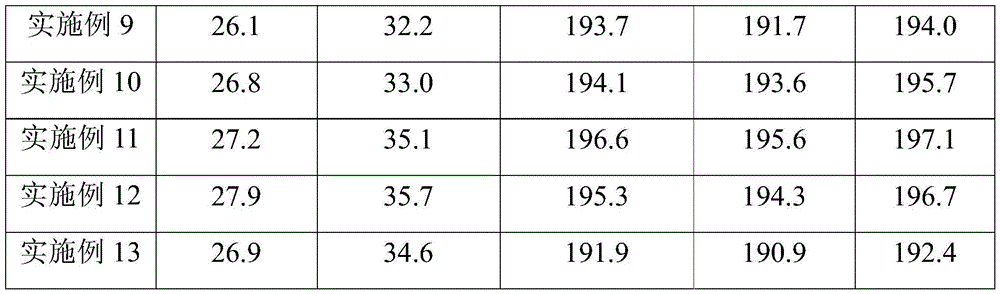

[0027] In this embodiment, a differential scanning calorimeter (Pyris 1DSC calorimeter from PerKinElmer, USA) is used to analyze the phase change heat storage material, and the test results are shown in Table 1.

Embodiment 2

[0029] A preparation method of a loaded semi-clathrate hydrate phase-change heat storage material (a load-type semi-clathrate hydrate phase-change heat storage material with a mass fraction of tetraisopentylammonium bromide of 35%) is as follows: 3.5g Add isopentyl ammonium bromide to 6.43g of water at a temperature of 60°C, stir to dissolve, then add 0.07g of expanded graphite, and stir at 60°C and 700r / min for 120 minutes to obtain a supported semi-cage hydrated Phase change thermal storage materials.

[0030] In this embodiment, a differential scanning calorimeter (Pyris 1DSC calorimeter from PerKinElmer, USA) is used to analyze the phase change heat storage material, and the test results are shown in Table 1.

Embodiment 3

[0032] A preparation method of a supported semi-clathrate hydrate phase-change heat storage material (a load-type semi-clathrate hydrate phase-change heat storage material with a mass fraction of tetraisopentylammonium bromide of 40%) is as follows: 4.0g tetra Add isopentyl ammonium bromide to 5.88g water at a temperature of 60°C, stir to dissolve, then add 0.12g of expanded graphite, and stir at 60°C and 700r / min for 120 minutes to obtain a supported semi-cage hydrated Phase change thermal storage materials.

[0033] In this embodiment, a differential scanning calorimeter (Pyris 1DSC calorimeter from PerKinElmer, USA) is used to analyze the phase change heat storage material, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com