Cleaning solvent special for anti-pollution flashover of high-voltage electrified-RTV

A high-voltage charging and anti-fouling flashover technology, applied in the field of cleaning agents, can solve the problems of difficult removal of dirt, poor ability to remove dirt, and damage to coatings, and achieve excellent wettability, good low foaming effect, and good emulsifying ability.

Active Publication Date: 2016-06-08

重庆洎皋电力科技有限责任公司

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Affected by the formulation and construction process, the strength and adhesion of RTV coatings vary greatly, and its surface friction is much greater than that of ordinary glass insulators and electric porcelain insulators. It is difficult to remove dirt when flushing with low-pressure water, and excessive flushing pressure Risk of damaging the coating by scrubbing with a rag

Common acid and alkali cleaning solutions are highly corrosive and destructive, and household detergents have poor decontamination ability and many foams, so they are not suitable for cleaning RTV paint insulators

The cleaning solvent for RTV coatings has also been developed in this technical field, but its operation is complicated and the cost is high, and for the cleaning of the surface of charged spraying type RTV coatings, there is no relevant public report in the prior art, because the used formula of charged spraying type RTV coatings Different from general RTV coatings, the technical problems to be overcome are different

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

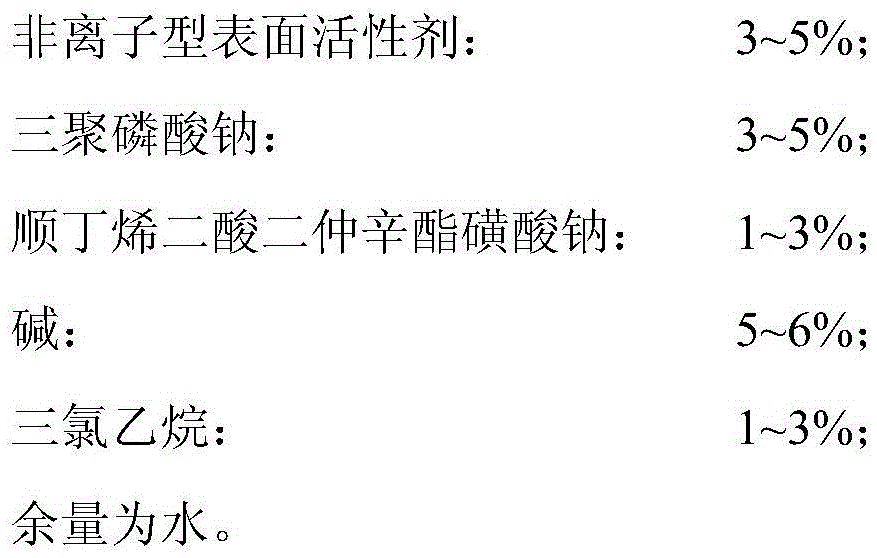

[0023] A kind of surface cleaning agent of charged spraying type RTV paint, by mass fraction, described cleaning agent composition is as follows:

[0024]

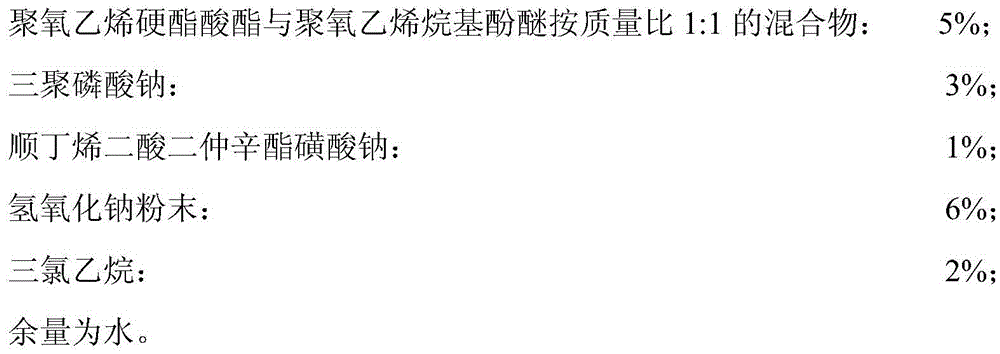

Embodiment 2

[0026]

[0027]

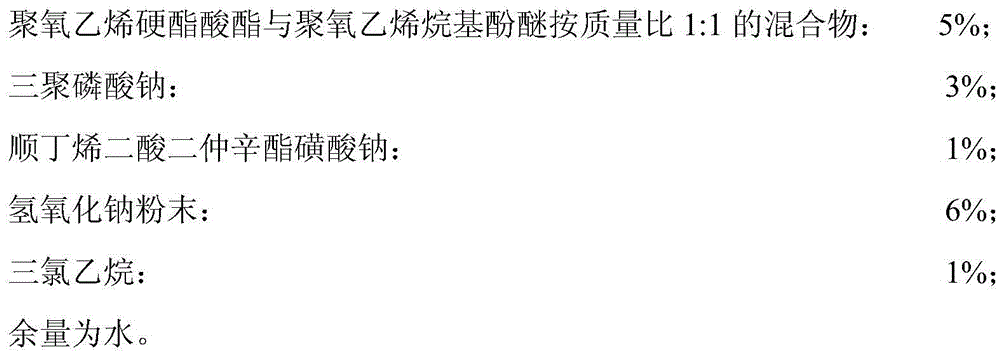

Embodiment 3

[0029]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a cleaning solvent special for anti-pollution flashover of high-voltage electrified-RTV. The cleaning agent is prepared from, by mass, 3-5% of a nonionic surfactant, 3-5% of sodium tripolyphosphate, 1-3% of sodium diethylhexyl sulfosuccinate, 5-6% of alkali, 1-3% of methyl chloroform and the balance water. According to the technical scheme, compared with an existing cleaning agent, the cleaning solvent can effectively remove dirt on the surface of an electrified-spraying type RTV paint insulator, the good hydrophobic nature and the good hydrophobic-migration performance of a coating can be restored, and safe operation of electric equipment can be ensured.

Description

technical field [0001] The invention belongs to the field of cleaning agents, in particular to a surface cleaning agent for charged spraying type RTV coatings. Background technique [0002] With the rapid development of my country's industry, the pollution of a large amount of emissions to the environment is increasing, and the pollution flashover accidents of power transmission and transformation equipment are frequent. The first choice for insulating anti-pollution flashover measures, but as an organic material, room temperature vulcanized rubber is subject to comprehensive utilization of surface discharge, ultraviolet radiation, and surface pollution, and aging phenomena are inevitable. Hydrophobic mobility is also lost. The deterioration of the external insulation performance of RTV will seriously threaten the safe and stable operation of the system. In addition, the RTV coating coated on the surface of the insulator is very thin, and the total amount of anti-pollution fl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C11D10/02

CPCC11D1/72C11D1/74C11D1/825C11D3/044C11D3/06C11D3/24C11D3/3472C11D3/43

Inventor 李学智任大义

Owner 重庆洎皋电力科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com