Large caterpillar crane floor board roadbed box

A technology of crawler cranes and subgrade boxes, applied in the field of subgrade boxes, which can solve the problems that reinforced concrete floors cannot meet the requirements of bearing capacity, poor engineering properties, low strength, etc., and achieve low cost of floor reinforcement, not easy to be damaged, and safe high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

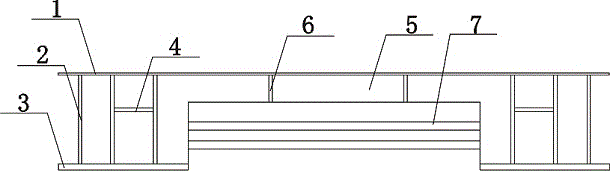

[0013] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0014] Such as figure 1 The preferred embodiment of the large-scale crawler crane floor subgrade box of the present invention shown in the present invention includes a cross beam 1, a vertical beam 2 is installed on the lower surface of the cross beam 1, and a threaded connection between the vertical beam 2 and the cross beam 1. There are two vertical beams 2 and two vertical beams. The beam 2 is set close to the two ends of the cross beam 1. The H-shaped steel beam 4 is installed on the inner side of the two vertical beams 2 and located on the lower surface of the cross beam 1. The bottom of the H-shaped steel beam 4 and the bottom of the vertical beam 2 are both loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com