Load balance type vertical axis wind turbine

A wind turbine and load balancing technology, applied in wind turbines, wind motor combinations, wind turbine assembly, etc., can solve problems such as difficulty in ensuring assembly quality, technical defects that cannot be changed in structure and mechanical properties, and high processing costs, achieving remarkable results Technical advantages and cost advantages, easy guarantee of processing quality, and small overall structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

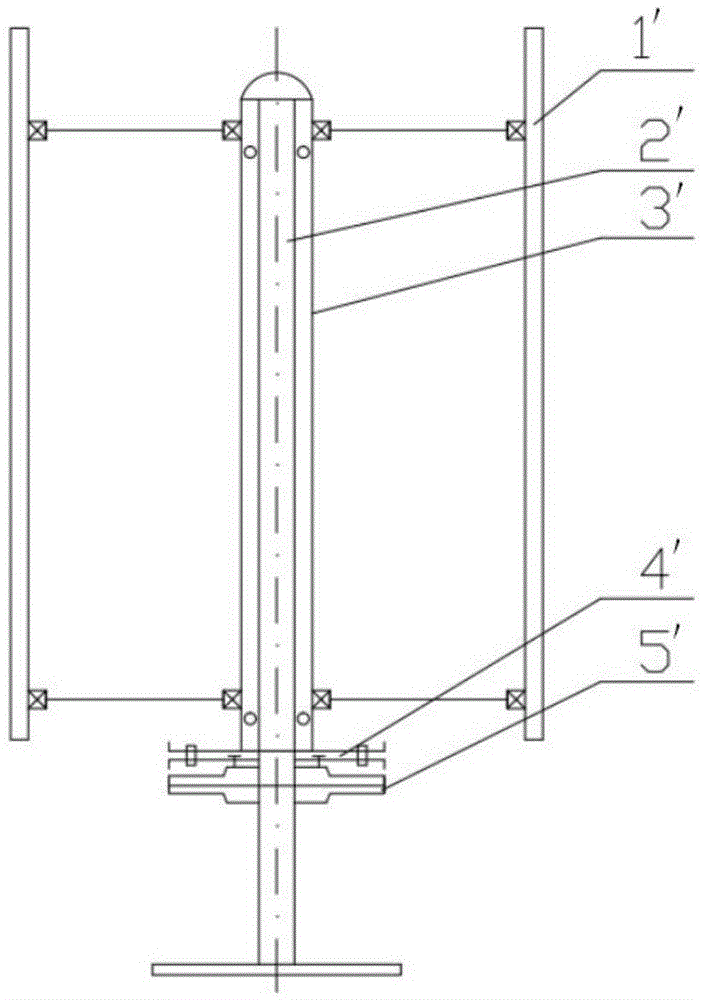

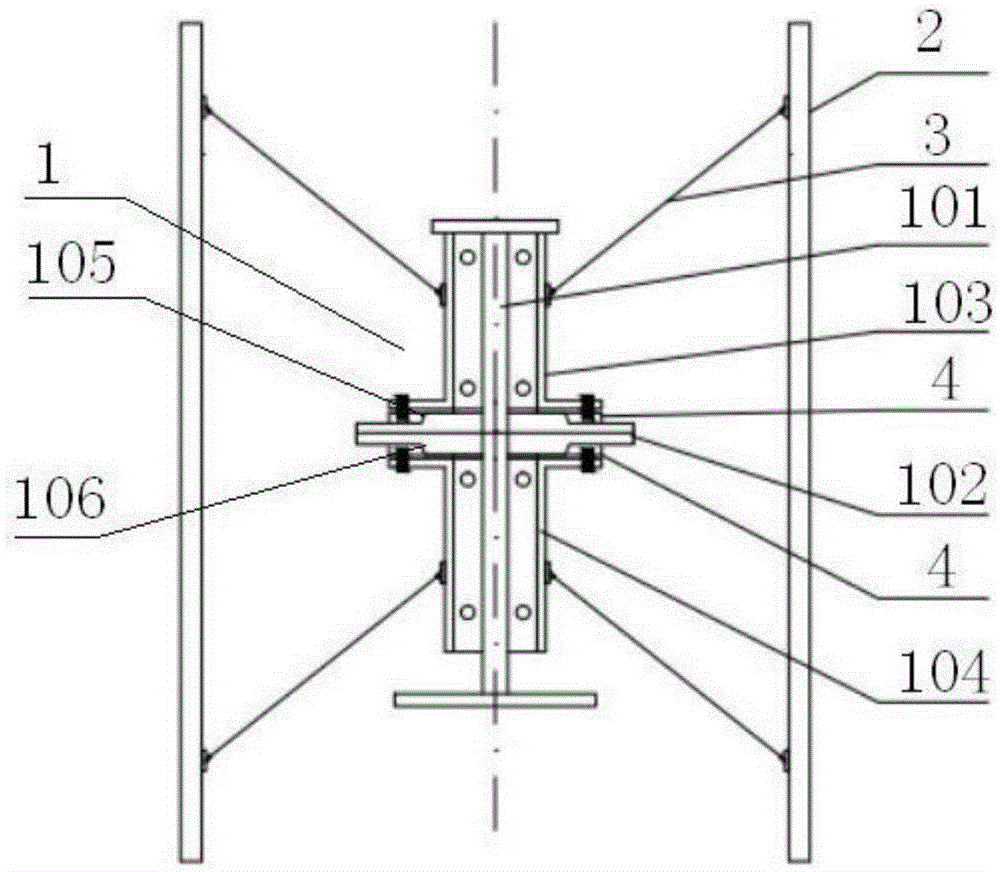

[0024] This embodiment provides a load-balanced vertical-axis wind turbine, such as figure 2 As shown, it includes a power transmission device 1 and a wind rotor blade 2, and a fixed rod 3 for fixing the wind rotor blade 2 to match the power transmission device 1; wherein, the power transmission device 1 includes a motor main shaft 101, which is arranged on the motor The motor 102 at the middle position of the main shaft 101, the upper rotary sleeve 103 fixedly arranged coaxially with the outer periphery of the motor main shaft 101 above the motor 102, and the lower rotary sleeve 103 fixedly arranged coaxially with the outer periphery of the motor main shaft 101 below the motor 102 104 ; the power transmission device 1 has an axisymmetric structure around the motor 102 . This embodiment adopts an axially symmetrical layout structure. When the generator system is running, under the action of wind force, the wind rotor blades 2 rotate, and act on the upper and lower rotor sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com