Tobacco seedling stage film uncovering machine

A technology of peeling film machine and tobacco seedlings, applied in plant protection cover, botanical equipment and methods, horticulture and other directions, can solve the problems of affecting the efficiency of crop production in mountainous areas, unable to peel off the film continuously, unstable operation, etc. Membrane efficiency, easy replacement, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

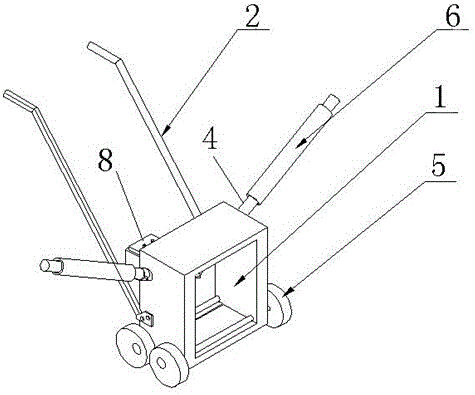

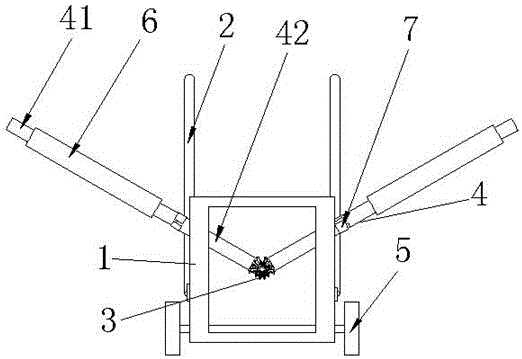

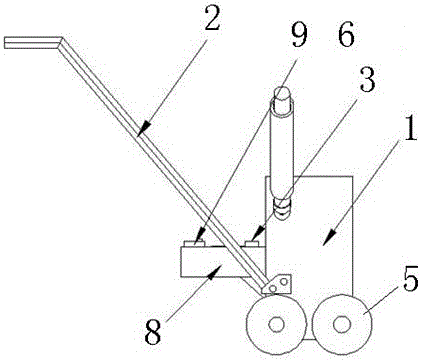

[0020] refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the present embodiment provides a tobacco seedling film removing machine, comprising a frame 1, a control armrest 2, a motor 3 and a transmission shaft 4, the lower end of the control armrest 2 is fixed on the frame 1, and the bottom of the frame 1 is provided with a walking Wheel 5, frame 1 is a box-shaped structure, and both sides of frame 1 are equipped with a transmission shaft 4, each transmission shaft 4 is stretched out from one side of its corresponding frame 1, and the output of motor 3 The shaft extends to the inside of the frame 1, and the output shaft of the motor 3 is arranged along the traveling direction of the road wheel 5, and the two transmission shafts 4 are perpendicular to the output shafts of the motor 3, and each transmission shaft 4 is formed by the transmission shaft I41 and The transmission shaft II42 is butted and combined. One end of the transmission shaft I41 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com