Milk and cereal beverage with quinoa malt and method for producing milk and cereal beverage

A technology of cereal beverage and malt milk, which is applied in the direction of food science, food ingredients as clouding agent, application, etc., can solve the problems of poor understanding of quinoa, and achieve the effect of improved flavor, broad market prospect, and white color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

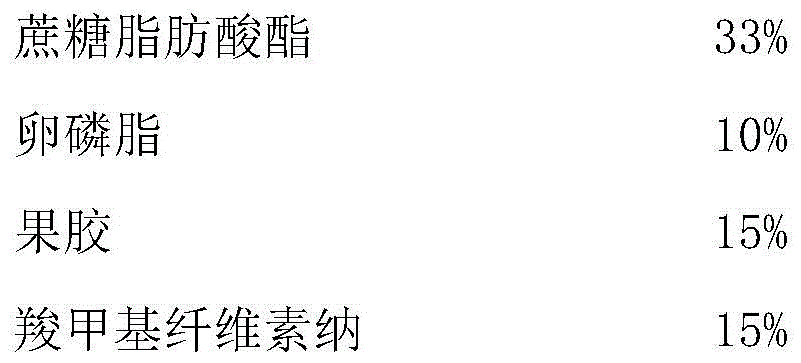

Embodiment 1

[0018] 1) Prepare fresh quinoa sprouts: first select the quinoa, select the quinoa with plump grains, good maturity, and no mildew, soak in 1% sodium hypochlorite solution for 35 seconds for disinfection, rinse repeatedly with clean water, and then soak in pure water After 3.5 hours, the sample was drained and spread on a germination tray, placed in an incubator at 22°C to germinate, sprayed with water every 7.5 hours during the germination process to maintain humidity, and germinated continuously for 4 days to obtain fresh quinoa sprouts;

[0019] 2) Preparation of quinoa germ puree: select well-germinated fresh quinoa sprouts, remove the shell and wash them, mix fresh quinoa sprouts with purified water at a weight ratio of 1:4, refine and homogenize Finally, filter through a 100-mesh sieve to remove slag, and obtain fresh quinoa germ puree with white color and outstanding quinoa flavor. The control conditions are: pure water temperature: 85°C; high pressure homogenization pre...

Embodiment 2

[0028] 1). The preparation methods of fresh quinoa germ, quinoa germ puree and compound emulsion stabilizer are the same as in Example 1.

[0029] 2). Deployment

[0030] Based on the preparation of 1,000 kg of quinoa malt milk products: 800 kg of fresh quinoa malt puree, 60 kg of xylitol, 5.5 kg of compound emulsion stabilizer and 134.5 kg of purified water;

[0031] Accurately weigh various raw and auxiliary materials required for the formula, first dry mix xylitol and compound emulsification stabilizer, dissolve with 100 kg of pure water, then mix with quinoa germ puree, and quantify to 1000 kg with pure water; Homogenization is carried out under the conditions of pressure 25MPa and temperature 70°C; the homogenized material is the product after ultra-high temperature instantaneous sterilization (121°C, 10S), hot filling (88°C), and packaging; the protein in the product is tested Content 1.88%, total flavonoid content 21.6mg / 100mL. After the product is centrifuged at 4000...

Embodiment 3

[0033] 1). The preparation methods of fresh quinoa germ, quinoa germ puree and compound emulsion stabilizer are the same as in Example 1.

[0034] 2). Deployment

[0035] Based on the preparation of 1000 kg of quinoa malt milk products: 700 kg of fresh quinoa malt puree, 70 kg of xylitol, 5 kg of compound emulsification stabilizer and 225 kg of purified water;

[0036] Accurately weigh various raw and auxiliary materials required for the formula, first dry mix xylitol and compound emulsification stabilizer, dissolve with 100 kg of pure water, then mix with quinoa germ puree, and quantify to 1000 kg with pure water; Homogenization is carried out under the conditions of pressure 25MPa and temperature 70°C; the homogenized material is the product after ultra-high temperature instantaneous sterilization (121°C, 10S), hot filling (88°C), and packaging; the protein in the product is tested Content 1.69%, total flavonoid content 18.5mg / 100mL. After the product is centrifuged at 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com