Solid biological bacterial fertilizer and preparation method thereof

A biological bacterial fertilizer and solid technology, which is applied in the preparation of organic fertilizers, the treatment of biological organic parts, organic fertilizers, etc., can solve the problems that affect the popularization and application of microbial fertilizers, are difficult to develop, and have no stability in the scientific evaluation of bacterial fertilizers. Fundamentally solve other problems, achieve the effect of easy to master the production process, improve sweetness, and inhibit harmful microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

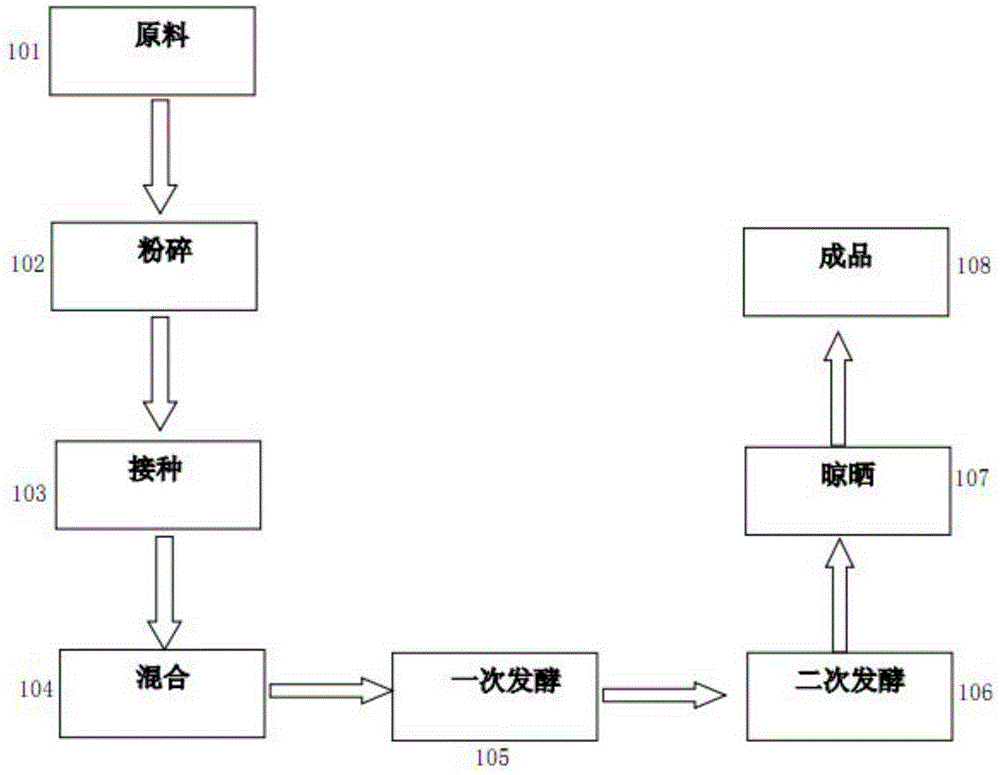

[0023] A method for preparing solid biological bacterial fertilizer is to subject raw material 101 to microbial fermentation treatment, and its specific operation process includes the following steps:

[0024] 1) The raw material 101 is calculated in parts by mass: 40 kg of corn stalks, 20 kg of animal manure, and the raw material 101 of corn stalks and animal manure is pulverized into 102 to 40 mesh powder;

[0025] 2) Add 5% high-efficiency flora fermentation broth based on the total mass percentage of corn stalks and animal manure to inoculate 103, and mix 104 evenly with the corn stalk powder and animal manure powder obtained in step 1), and transfer to the fermentation tank for further Fermentation treatment; the first fermentation 105 is aerobic fermentation, the time of fermentation 105 is 5 days, the moisture of fermentation 105 is controlled at about 60%, the second fermentation 106 is anaerobic fermentation, the time of fermentation 106 is 10 days, and the moisture of...

Embodiment 2

[0028] A method for preparing solid biological bacterial fertilizer is to subject raw material 101 to microbial fermentation treatment, and its specific operation process includes the following steps:

[0029] 1) The raw material 101 is calculated in parts by mass: 40 kg of corn stalks, 20 kg of animal manure, and the raw material 101 of corn stalks and animal manure is pulverized into 102 to 30 mesh powder;

[0030] 2) Add 7% of the high-efficiency flora fermentation broth based on the total mass percentage of corn stalks and animal manure to inoculate 103, and mix 104 with the corn stalk powder and animal manure powder obtained in step 1), and transfer to the fermentation tank for further Fermentation treatment: the first fermentation 105 is aerobic fermentation, the time of fermentation 105 is 7 days, the moisture of fermentation 105 is controlled at about 55%, the second fermentation 106 is anaerobic fermentation, the time of fermentation 106 is 12 days, and the moisture of...

Embodiment 3

[0033] A method for preparing solid biological bacterial fertilizer is to subject raw material 101 to microbial fermentation treatment, and its specific operation process includes the following steps:

[0034] 1) The raw material 101 is calculated in parts by mass: 40 kg of corn stalks, 20 kg of animal manure, and the raw material 101 of corn stalks and animal manure is pulverized into 102 to 20 mesh powder;

[0035] 2) Add 10% of the high-efficiency flora fermentation broth based on the total mass percentage of corn stalks and animal manure to inoculate 103, and mix 104 with the corn stalk powder and animal manure powder obtained in step 1), and transfer to the fermentation tank for further Fermentation treatment; the first fermentation 105 is aerobic fermentation, the time of fermentation 105 is 10 days, the moisture of fermentation 105 is controlled at about 50%, the second fermentation 106 is anaerobic fermentation, the time of fermentation 106 is 15 days, and the moisture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com