Coating uniformity online detection system and method for paper-making reconstituted tobacco

A technology of reconstituted tobacco leaves and detection system, which is applied to tobacco, measuring device, tobacco preparation, etc., can solve the problems of inability to intelligently control coating uniformity, inability to realize coating uniformity detection, and no coating uniformity analysis, etc. It is easy to adjust the control in time, the sampling speed is fast, and the detection speed is fast.

Active Publication Date: 2016-06-15

QUANZHOU INST OF EQUIP MFG

View PDF11 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the problem of this device is: complex operation, offline operation, cannot meet the needs of online operation, and does not analyze the coating uniformity

However, the problem with this device is that it is necessary to detect the solid content of the coating liquid on the film base, the operation is complicated, the detection of the coating uniformity cannot be realized, and the real-time intelligent control of the coating uniformity cannot be realized.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

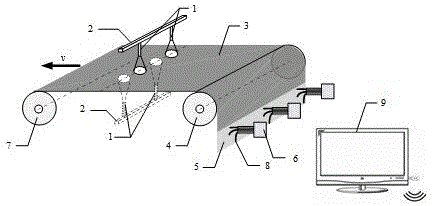

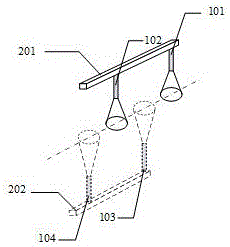

[0065] figure 1 It is a schematic diagram of the online detection system for coating uniformity of reconstituted tobacco leaves of the present invention. It can be seen from the figure that the system structure includes: the device includes a near-infrared spectrum detection device 1, a mechanical motion scanning device 2, a reconstituted tobacco leaf conveying device 7, and a uniform coating Sex intelligent control device 6 and computer 9;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

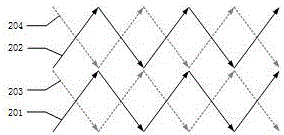

The invention discloses a coating uniformity online detection system for paper-making reconstituted tobacco. The detection system comprises a near-infrared spectrum detection device, a mechanical movement scanning device, a reconstituted tobacco transferring device, a coating uniformity intelligent control device and a computer. A detector moves in a staggered mode to acquire spectrum data of different positions of reconstituted tobacco, and online fast detection of coating uniformity is achieved by means of a data processing and analyzing algorithm. The coating uniformity online detection system for the paper-making reconstituted tobacco performs real-time online detection on coating uniformity of the reconstituted tobacco in the production process, detection speed is high, and detection precision is high. When a detection result does not accord with requirements of uniformity production, information is fed back, coating uniformity can be conveniently controlled, production quality of the paper-making reconstituted tobacco is guaranteed, and production efficiency is improved.

Description

technical field [0001] The invention relates to a system for detecting coating uniformity of reconstituted tobacco leaves by papermaking method, in particular to an online detection system and detection method for coating uniformity of reconstituted tobacco leaves by papermaking method using near-infrared spectrum analysis technology. Background technique [0002] Reconstituted tobacco leaves are sheet or silk regenerated tobacco products (also called tobacco flakes) made by technically processing and recombining tobacco residues such as tobacco powder, shredded stems, and chips during cigarette processing. For the process quality control of reconstituted tobacco leaf products, the current production line has online control equipment for moisture, temperature, slurry concentration and density indicators, and other quality control is blank. Most of them are offline detection, and the results are lagging behind. Strong, such as online detection and feedback of product quantifi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A24B3/14G01N21/3563G01N21/359

CPCA24B3/14G01N21/3563G01N21/359

Inventor 韩军吴飞斌龙晋桓

Owner QUANZHOU INST OF EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com