A compound biological agent microcapsules that can improve the sensory quality of tobacco leaves

A technology of biological preparations and microcapsules, which is applied in the fields of tobacco, food science, and tobacco preparation, can solve the problems of alcoholization of tobacco leaves that have not been seen, and achieve the effects of shortening the aging time of tobacco leaves, accelerating degradation, and important application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

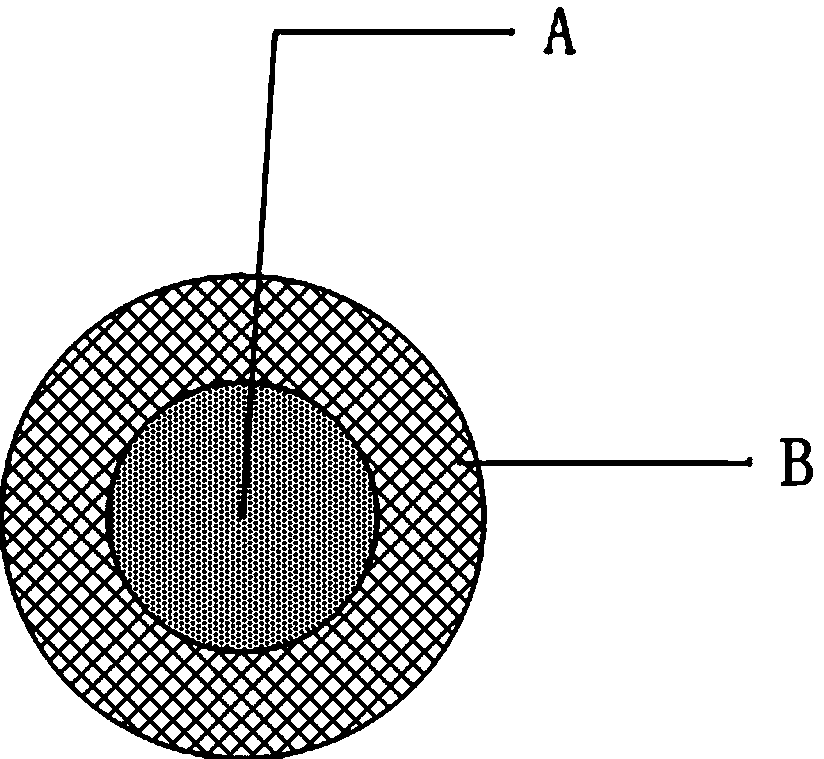

Image

Examples

Embodiment 1

[0046] The composite biological agent microcapsules provided in this example for improving the sensory quality of tobacco leaves are prepared according to the following steps.

[0047] (1) Preparation of core material:

[0048] The Bacillus subtilis bacterial solution is prepared as follows: take the Bacillus subtilis strain, LB liquid medium, 30°C, 200 rpm shaker culture and amplification, use the sterile culture medium as the blank control, and record the concentration of the bacterial solution at 600 nm The absorbance value of OD 600 , when OD 600 =6.0, as the application of bacterial agent, the count at this time shows that the number of bacteria in the bacterial liquid=7 billion / mL (specifically 7.02×10 9 cfu / mL);

[0049] The sphingomonas bacteria solution was prepared as follows: take the sphingomonas bacteria strain and the inorganic salt liquid medium, culture and amplify it on a shaker at 30°C and 200 rpm, and use the sterile culture solution as a blank control. ...

Embodiment 2

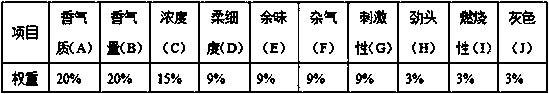

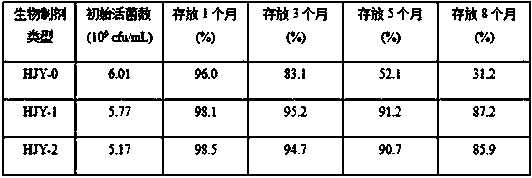

[0070] After blending HJY-0, HJY-1, and HJY-2 prepared in Example 1 with tobacco leaves in a certain proportion, the tobacco leaves were still placed in the tobacco warehouse for storage. During the storage of the tobacco leaves, samples were taken every two months. The treated tobacco leaves were evaluated. The quality changes of tobacco leaves under different treatments are introduced as follows.

[0071] The changes in the quality of tobacco leaves without adding bacterial agents (blank control) are shown in the table below:

[0072] .

[0073] When HJY-0 is used to treat tobacco leaves, add 1.0% of the mass of the tobacco leaves. The changes in the quality of the tobacco leaves after treatment are shown in the table below:

[0074] .

[0075] When HJY-1 is used to treat tobacco leaves, it is added at a rate of 2.0% of the mass of the tobacco leaves. The changes in the quality of the tobacco leaves after treatment are shown in the table below:

[0076] .

[0077]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com