Fresh product cistanche salsa raw material processing method

A technology of raw material processing and cistanche, which is applied in plant raw materials, medical formulas, medical preparations containing active ingredients, etc., can solve the problems of reduced content of active ingredients, difficulty in processing and cutting decoction pieces, serious lignification of raw materials, etc., and achieve good quality , soft texture, reducing the effect of intermediate links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

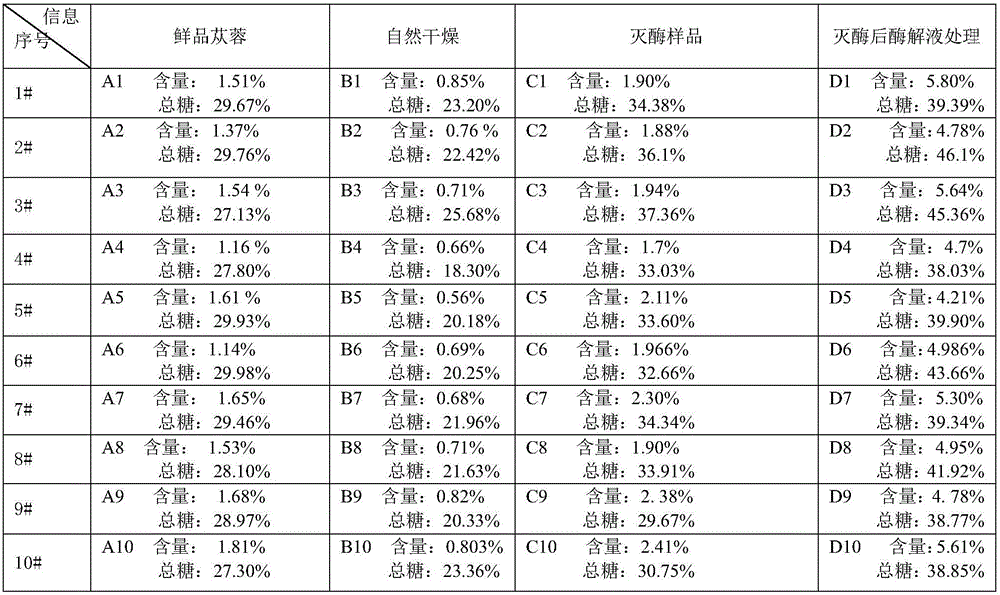

Embodiment 1

[0019] Fresh cistanche is selected and cleaned, and enzymes are killed: put the cleaned cistanche in a single layer in a tray, and after the moistening machine is heated to 80°C, put the tray containing fresh cistanche into it, and use steam to kill enzymes. The time is 25 minutes; Drying: Put the cistanche in an oven at 60°C for 7 hours, then dry it naturally until it is 7-80% dry. During the natural drying process, turn the cistanche twice a day, once in the morning and once in the evening.

[0020] The degree of lignification of Cistanche deserticola after treatment was 3.2%.

Embodiment 2

[0022] Preparation of enzymolysis solution: After Cistanche is crushed, add 8 parts of water and mix; add 0.5% cellulase of the quality of Cistanche for enzymolysis, enzymolysis conditions control temperature at 52°C, ph5, enzymolysis time 4 hours; fresh Cistanche selection After cleaning, put it into the enzymatic solution at 88°C for 15 seconds, and use electric shock treatment for 8 seconds in the middle; then put it in a medicine moistening machine at 91°C, and treat it with steam for 5 minutes: Drying: Put Cistanche in an oven at 60°C for 7 hours Place it in a place out of direct sunlight and dry it naturally until it is 70-80% dry. During the natural drying process, turn the Cistanche 2 times a day, once in the morning and once in the evening.

[0023] The electric shock treatment conditions are: electric field intensity 30kV / cm, pulse time 400μs, pulse frequency 300Hz.

Embodiment 3

[0025] Preparation of enzymatic hydrolysis solution: after crushing Cistanche deserticola, add 10 parts of water and mix; add 1% cellulase of Cistanche deserticola mass for enzymolysis, the enzymatic hydrolysis conditions control temperature at 58°C, pH 4.5, enzymolysis time 6 hours; fresh product Cistanche is selected and cleaned, put into 89°C enzymolysis solution and placed for 19 seconds, and electric shock treatment is used for 10 seconds in the middle; then placed in 88°C moistening machine, treated with steam for 6 minutes: Drying: put Cistanche in an oven at 60°C and bake for 8 After 1 hour, place it in a place where it cannot be exposed to direct sunlight and dry it naturally until it is 70-80% dry. During the natural drying process, turn the Cistanche 2 times a day, once in the morning and once in the evening.

[0026] The electric shock treatment conditions are: electric field intensity 20kV / cm, pulse time 500μs, pulse frequency 200Hz.

[0027] The degree of lignifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com