An ionic wind air purifier

An air purifier and ion wind technology, which is applied in the field of purifiers, can solve problems such as damage to insulation performance, aggravate tracking, corrosion, etc., and achieve the effects of improving yield, improving customer experience, and avoiding concerns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

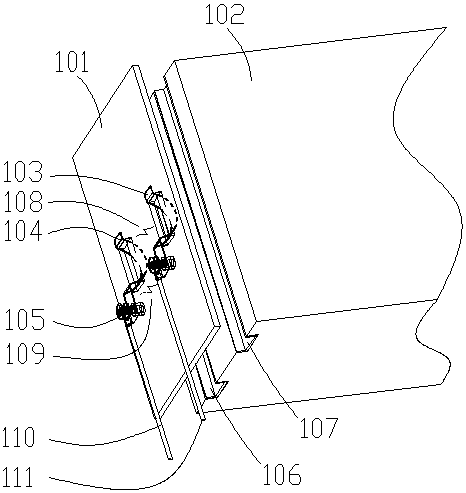

Image

Examples

Embodiment Construction

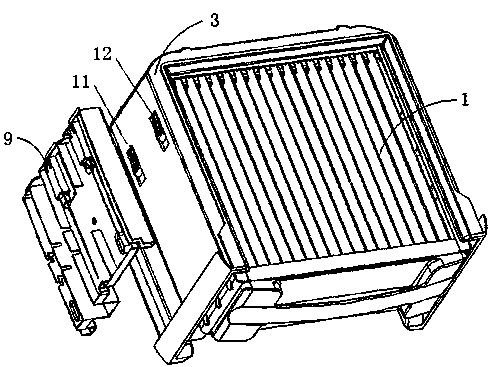

[0031] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

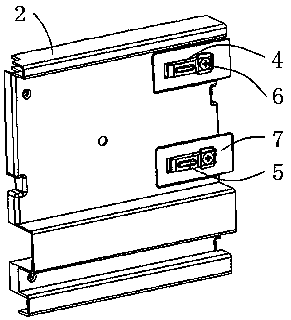

[0032] Such as figure 2 As shown, an ion wind air purifier includes an electrostatic precipitator 1 and a fixed structure 2, the electrostatic precipitator 1 is provided with an electrostatic precipitator protective cover 3, and the electrostatic precipitator protective cover 3 is designed The purpose is to prevent the electrostatic precipitator 1 from being impacted and in contact with rough and corrosive substances during use, and to better prolong the life of the electrostatic precipitator.

[0033] One side of the electrostatic precipitator is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com