Silicon ingot cutting machine with novel hypersensitive wire break alarm devices

A disconnection alarm and high-sensitivity technology, which is applied to fine working devices, working accessories, stone processing equipment, etc., can solve problems such as poor detection effect, and achieve the effect of improving alarm effect, sensitivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

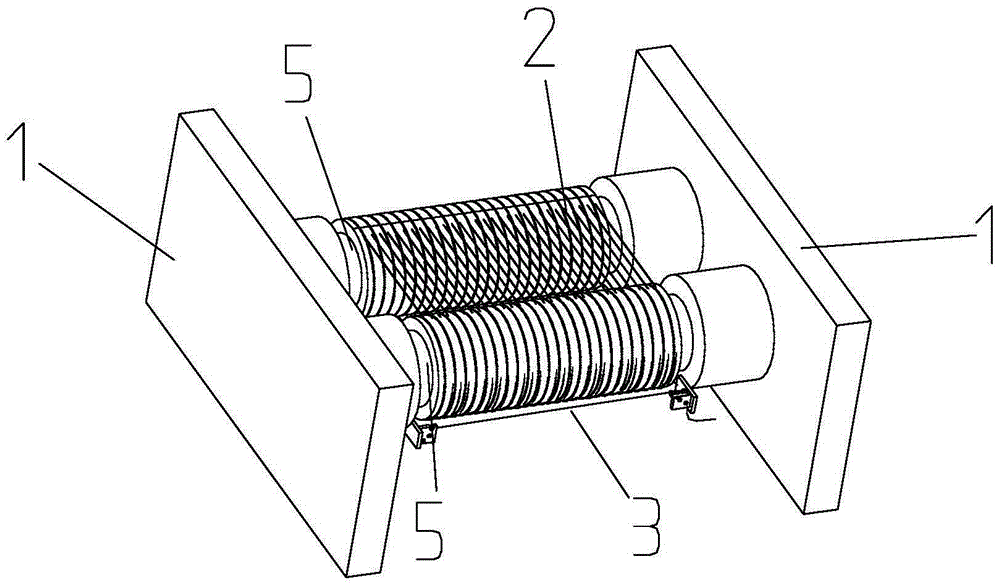

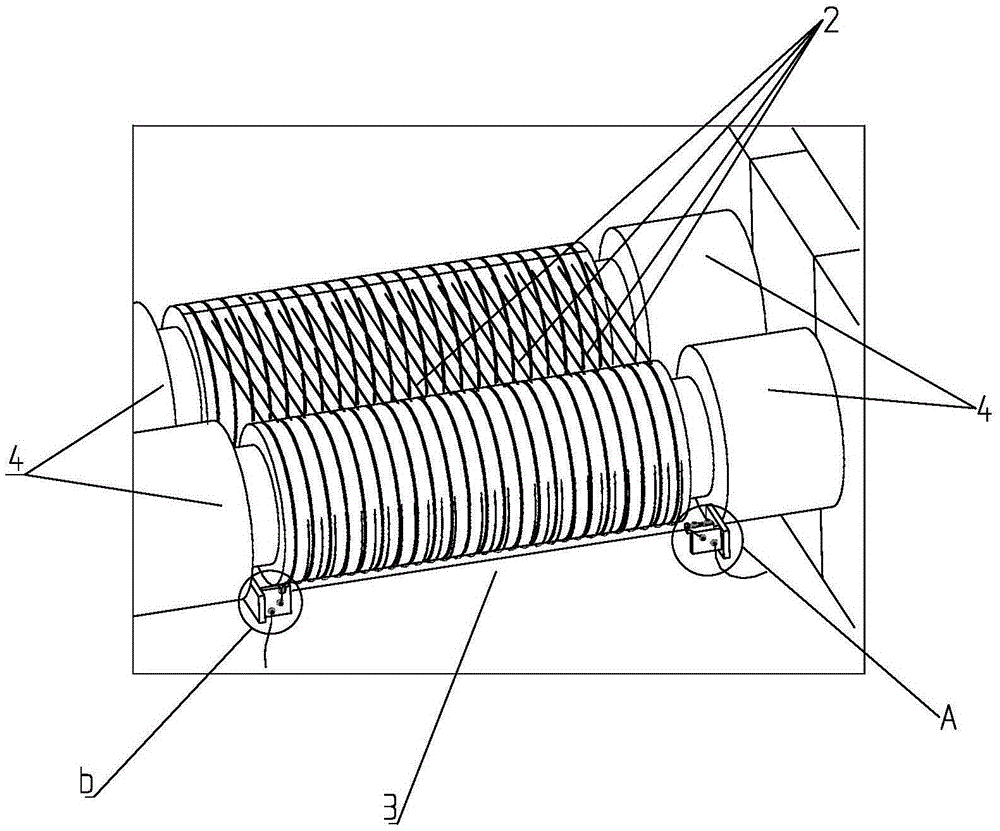

[0030] Embodiment one, such as figure 1 , figure 2 As shown, the present invention provides a novel high-sensitivity disconnection alarm device, which includes a disconnection alarm device, a cutting line, a main roller, and a main control unit. Bearing boxes 4 are set, the number of bearing boxes is 4, two pairs, each pair of bearing boxes is facing each other, and a main roller is carried between each pair of bearing boxes, so that the main roller is erected in the frame , the number of main rollers is two and the two main rollers are parallel. A metal cutting line 2 for cutting silicon ingots surrounds the two main rollers, and the cutting line surrounds the main rollers to form a wire mesh.

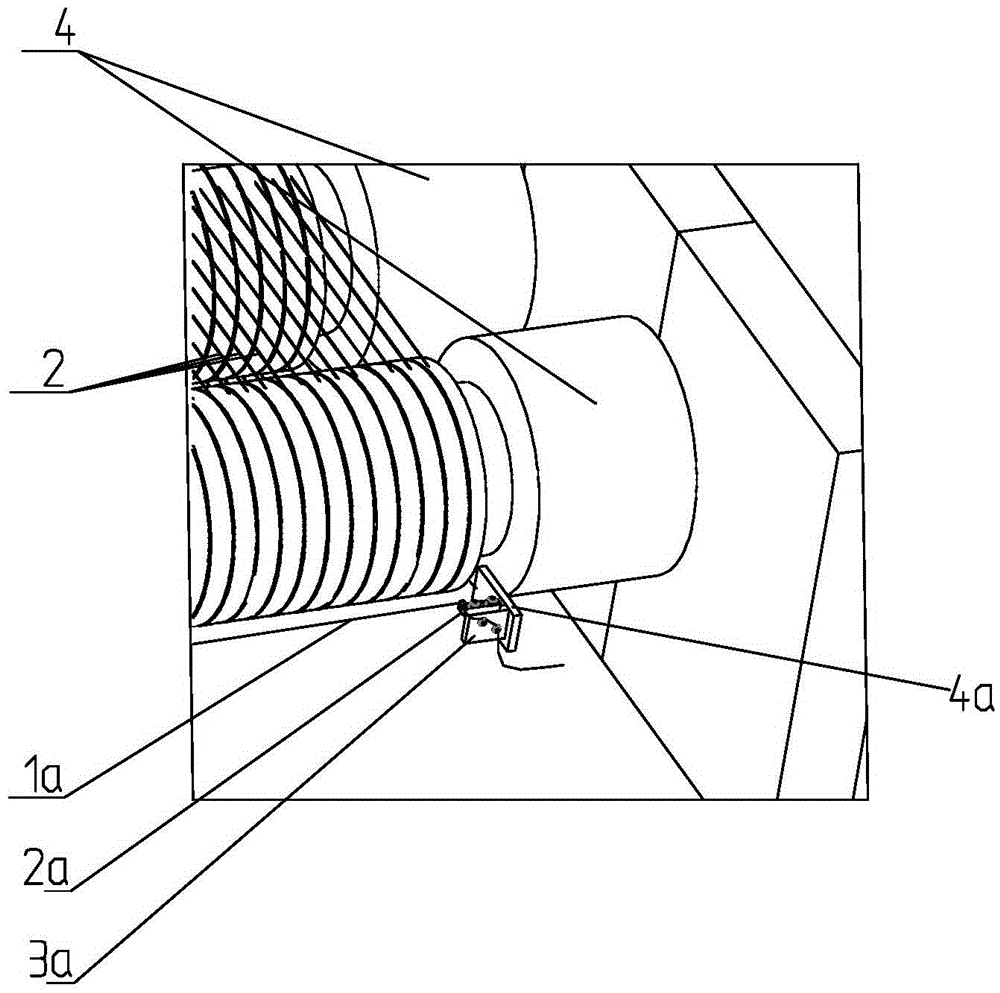

[0031] Such as figure 2 , Image 6 As shown, when the cutting line is in contact with the semi-arc surface of the outer peripheral surface of the main roller, the outer peripheral surface of the main roller can be formed by setting the two arc-shaped surfaces to meet each other,...

Embodiment 2

[0035] Embodiment 2, in order to ensure a good detection effect, it also includes a control detection unit, a power supply and a disconnection detection relay, and a short circuit detection unit. The control detection unit is used to control the operation of the entire cutting device automation system for the retraction and release of the steel wire , the metal sensing line is connected to the sensing signal input terminal of the control detection unit, the disconnection detection relay is connected in parallel with the metal sensing line, and the disconnection signal output terminal of the disconnection detection relay is connected to the disconnection signal receiving end of the control detection unit , the metal induction line is energized, the metal induction line, the control detection unit and the disconnection detection relay are all powered by the power supply, the short-circuit detection unit is integrated in the control detection unit, and the short-circuit detection u...

Embodiment 3

[0036]Embodiment 3, in order to ensure a good cutting effect, the diameter of the metal induction wire is 0.1 mm and the metal induction wire is located under the side of the main roller, and the horizontal plane where the metal induction wire is located is in the middle of the metal induction wire. The angle between the point and the midpoint of the main roller is greater than or equal to 45° and less than 90°, when the angle between the midpoint of the metal induction line and the midpoint of the main roller is equal to 45°, the arc length of the cutting line is broken It is equal to the distance between the metal induction line and the monitoring surface of the main roller. When the angle between the midpoint of the metal induction line and the middle point of the main roller is greater than 45°, the arc length of the cutting line is longer than that of the metal induction line to the main roller monitoring The distance between the two surfaces ensures that within this angle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap