A logistics automatic transmission system and its transmission method used in extreme environments

An automatic transmission, extreme environment technology, used in conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as being unsuitable for transporting heavy products, people prone to moisture and corrosion, and elongation of conveyor belts, to simplify artificial products. Inspection procedures, easy to operate and control transmission, the effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

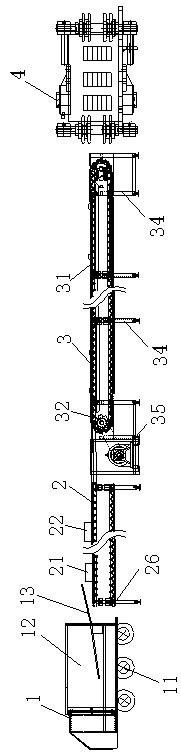

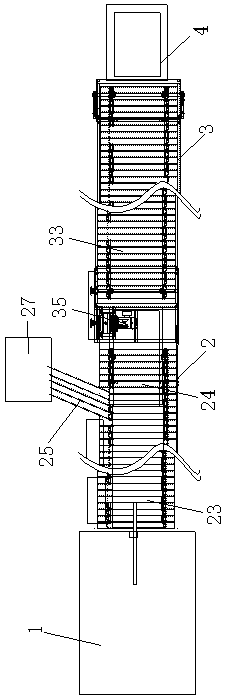

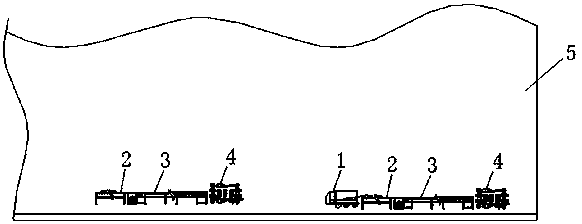

[0025] An automatic logistics transmission system used in extreme environments, set in a closed operating space 5, mainly includes an electrically connected logistics transmission system and a remote control system, and the logistics transmission system mainly includes transmission tools 1, The sorting mechanism 2, the conveyor belt mechanism 3 and the packaging mechanism 4, wherein, the conveying tool 1 is a remote-controlled product loading and unloading vehicle, mainly including an all-wheel drive device 11, a loading compartment 12 and a loading and unloading track 13, and the loading compartment 12 An open structure consisting of a top and a side opening is surrounded by a bottom plate and three walls. The loading and unloading track 13 is a long straight track-shaped adjustable and inclined loading and unloading track 13. A support adjustment base is installed on the left side of the bottom of the track. The loading and unloading track 13 is installed on the bottom edge o...

Embodiment 2

[0035] An automatic logistics transmission system used in extreme environments, set in a closed operating space 5, mainly includes an electrically connected logistics transmission system and a remote control system, and the logistics transmission system mainly includes transmission tools 1, The sorting mechanism 2 and the conveyor belt mechanism 3 are then transferred to other tooling stations, wherein the transfer tool 1 is a remote-controlled product loading and unloading vehicle, which mainly includes an all-wheel drive device 11 for controlling orientation transfer, a loading compartment 12 and The loading and unloading track 13, the load compartment 12 is surrounded by a bottom plate and three walls to form an open structure with a top and a side opening. The loading and unloading track 13 is an adjustable inclined loading and unloading track 13 in the shape of a long straight track. A support adjustment base is installed, and the loading and unloading track 13 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com