Phosphide-modified silicon-based photoelectric cathode material and preparation method thereof

A photocathode and phosphide technology, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve problems such as catalyst blockage, catalytic activity reduction, and adverse effects of electron transmission, and achieve the effect of overcoming corrosion and improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

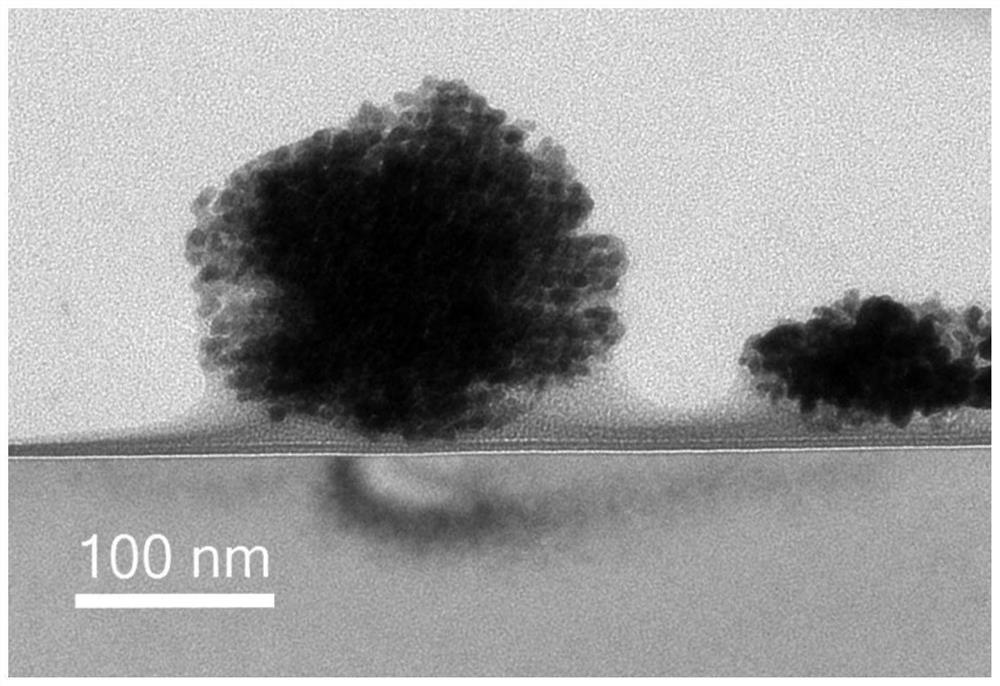

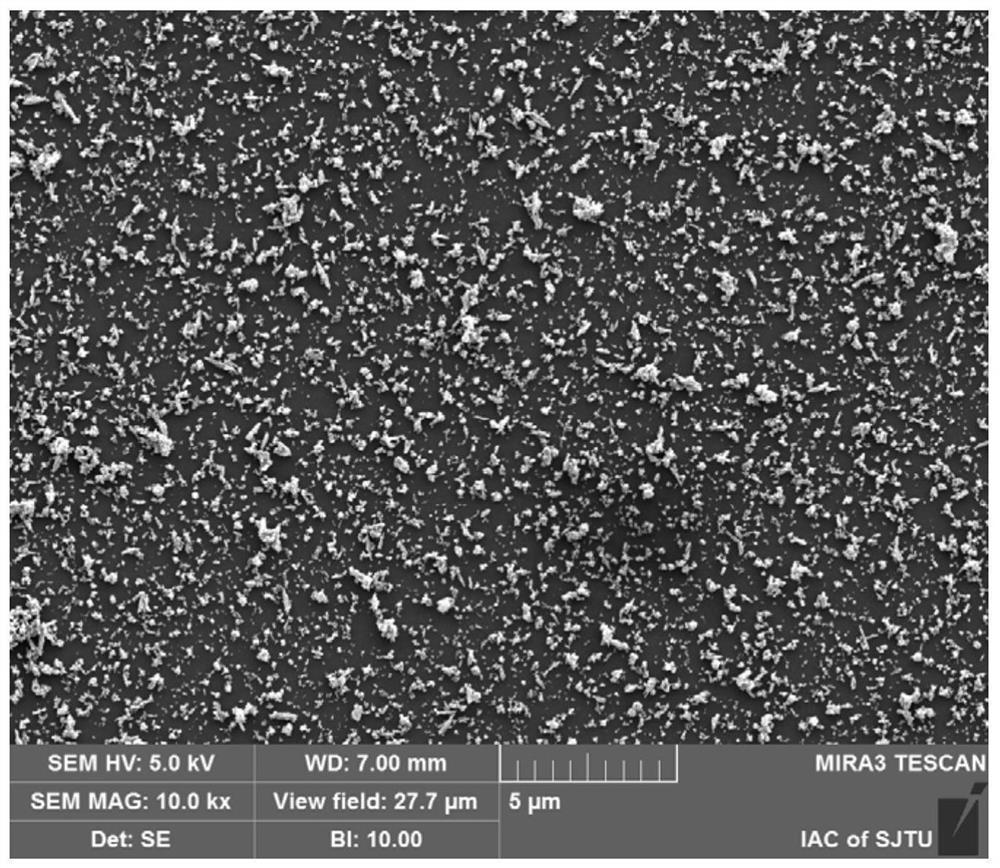

Embodiment 1

[0027] Cut p-type single-sided polished silicon with a resistance value of 1-10Ω into 2cm×2cm, ultrasonically clean it with deionized water, ethanol and acetone for 30min, then immerse in 5% HF solution for 10min, rinse with deionized water and blow with nitrogen Dry, place in the atomic layer deposition system, use tetrakis(dimethylamino)titanium and water as reaction precursors, deposit 125 cycles at 150°C, and obtain TiO with a thickness of 5nm 2 . The WP particles with mesoporous structure were dispersed in a mixture of methanol (50%) and ethanol (50%), and ultrasonicated for 30 min to obtain a 10 mg / mL dispersion. Then take 100uL of WP dispersion and spin coat on TiO 2 / Si substrate, the rotation speed is 3000r / min, and the time is 60s. Configure TiCl with a concentration of 0.01mol / L 4 The methanol dispersion is spin-coated on the surface of the silicon wafer at a spin speed of 3000r / min for 60s. Put the silicon wafer in an oven at 60°C for 10 minutes, then place it ...

Embodiment 2

[0029] Cut p-type single-sided polished silicon with a resistance value of 5-15Ω into 2cm×2cm, ultrasonically clean it with deionized water, ethanol and acetone for 30min, then immerse in 5% HF solution for 10min, rinse with deionized water and blow with nitrogen Dry, place in the atomic layer deposition system, use tetrakis(dimethylamino)titanium and water as reaction precursors, deposit 250 cycles at 150°C, and obtain TiO with a thickness of 10nm 2 . Disperse the mesoporous MoP powder in a mixture of methanol (50%) and ethanol (50%), and sonicate for 30 min to obtain a 10 mg / mL dispersion. Then take 100uL of MoP dispersion and spin-coat on TiO 2 / Si substrate, the rotation speed is 4000r / min, and the time is 60s. Configure TiCl with a concentration of 0.1mol / L 4 The methanol dispersion is spin-coated on the surface of the silicon wafer at a spin speed of 5000r / min for 60s. Put the silicon wafer in an oven at 60°C for 10 minutes, then place it in a tube furnace with argon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com