Method for alleviating corrosion of boiler preheater

A preheater and boiler technology, applied in the field of corrosion, can solve the problems of reducing the combustion efficiency of the boiler and the service life of the boiler, and the boiler preheater is prone to corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0022] According to the method of the present invention, the fuel of the boiler can be various conventionally used fuels, such as at least one of crushed coal, pulverized coal, coal water slurry, and coal gas. The method of the present invention is particularly suitable for metallurgical gas It is a fuel boiler system. Therefore, according to a preferred embodiment of the present invention, the fuel of the boiler is a fuel containing metallurgical gas.

[0023] The metallurgical gas refers to the combustible gas containing carbon monoxide produced in the metallurgical process, especially the iron and steel metallurgical process, such as blast furnace gas, converter gas, coke oven gas and producer gas. The calorific value of metallurgical gas is generally 2-20MJ / m 3 .

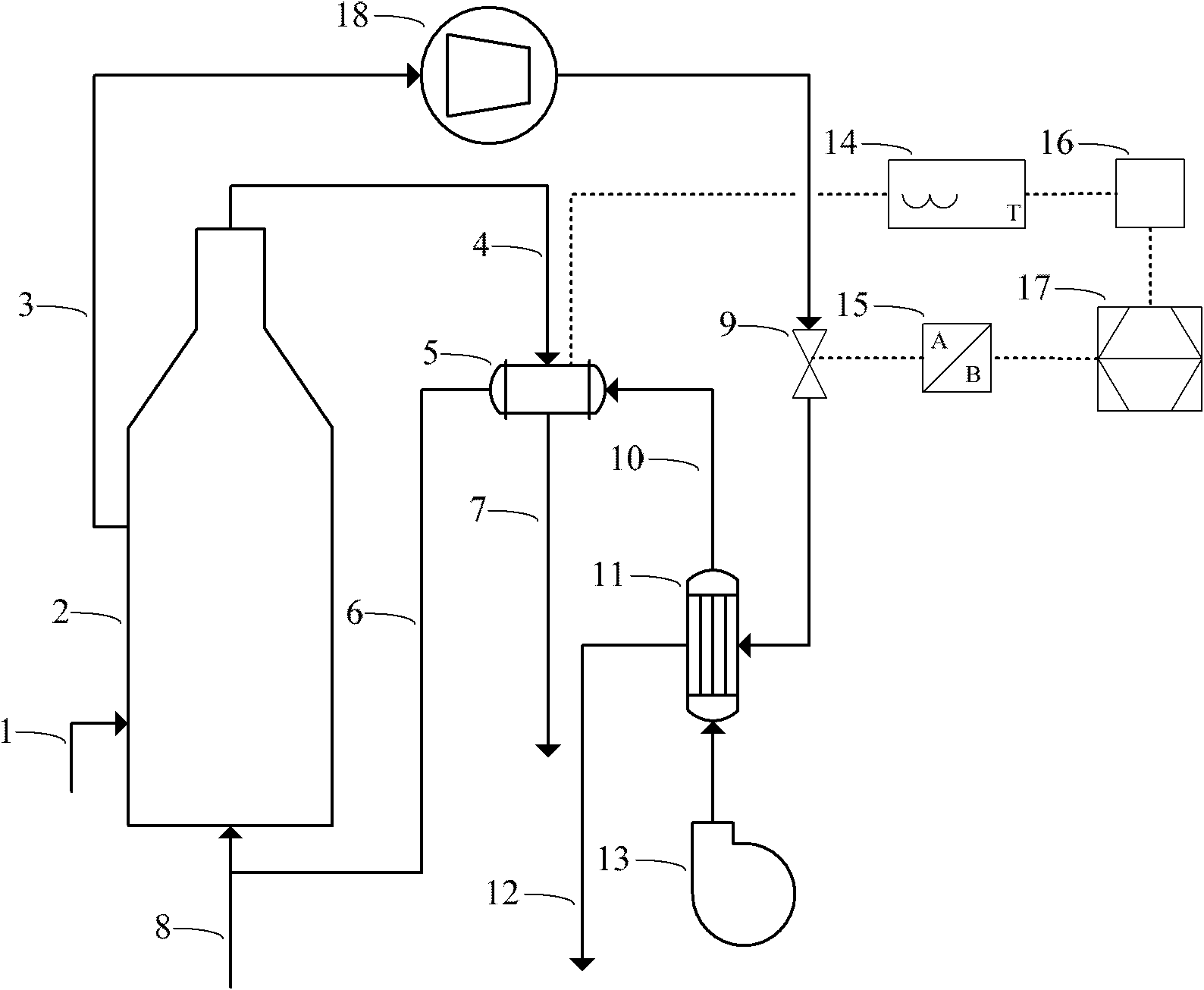

[0024] According to a particularly preferred preferred embodiment of the present invention, the method of the present invention is achieved by figure 1 The system shown is implemented. Among them, the water passing...

Embodiment 1

[0031] use figure 1 In the system shown, the water (approximately 215°C) that pipe 1 passes into boiler 2 is heated in boiler 2 to steam (9.8MPa, 535°C) and is exported through pipe 3 and used for steam turbine 18 to generate electricity. After steam (0.9MPa, 310°C).

[0032] The waste steam used for the power generation of the steam turbine 18 passes through the valve 9 and then enters the heat exchanger 11. The blower 13 reduces the combustion air (about 15°C) to 110000Nm 3 The flow rate of / h is sent to the heat exchanger 11, which is used for heat exchange between the waste steam generated by the steam turbine 18 and the combustion-supporting air, and then is exported through the pipe 12; the heat-exchanged combustion-supporting air (90-100°C) enters the installation through the pipe 10 In the boiler preheater 5 in the flue 4. The heat-exchanged combustion-supporting air in the boiler preheater 5 and the flue gas in the flue 4 form a countercurrent heat conduction contact, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com