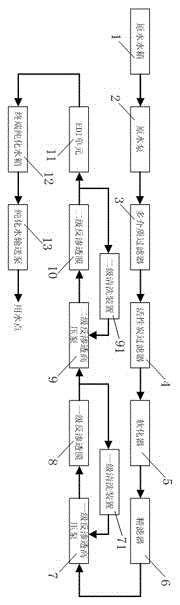

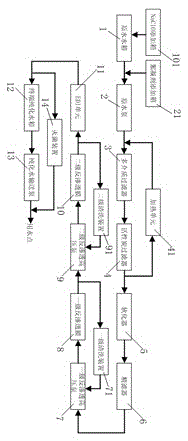

Purified water preparation system

A preparation system and purified water technology, applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve problems such as high production, operation and maintenance costs, complex systems, slow filtration speed and clean areas, and achieve operation The effect of low cost, good solubility and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Raw water supply buffer flushing time of raw water tank 1: not less than 15Mins.

[0034] NaClO Adding Box 101 The dosage of NaClO is generally controlled at 0.3-0.5ppm, which should not be too high or low, and the dosage should be adjusted according to the test value in the raw water.

[0035] Multi-media filter 3, operating flow rate: 8-12m / h; depth of filter layer: ≥1200mm; pressure drop: 0.5bar; filter material: anthracite, quartz sand, etc.

[0036] Activated carbon filter 4, operating flow rate: 10-15m / h; depth of filter layer: ≥1200mm; pressure drop: 0.5bar; filter material: coconut shell activated carbon.

[0037] Softener 5, operating flow rate: 10-25m / h; resin layer height: ≥1200mm; regeneration solution: 8-10% saline.

[0038]The first-stage reverse osmosis membrane 8 points water production design parameters, the water recovery rate of the reverse osmosis device: 70%; the initial desalination rate of the reverse osmosis membrane device: ≥97%.

[0039] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com